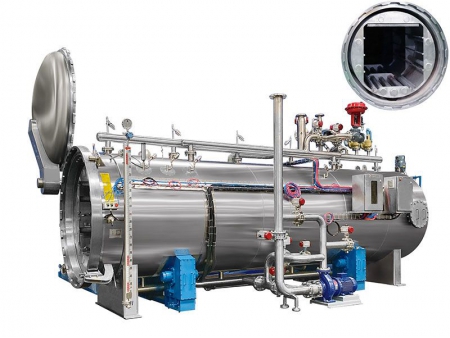

Spray Retort

Request a Quote

Sterilization Retort for Sauces and Condiments

How It Works

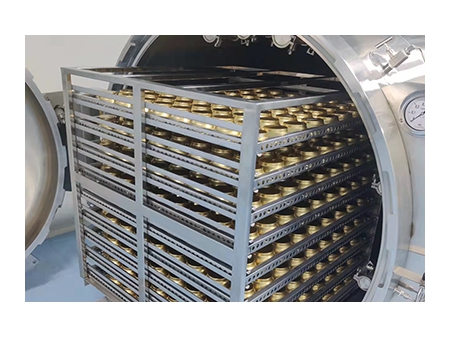

- Filling the Autoclave and Water Injection

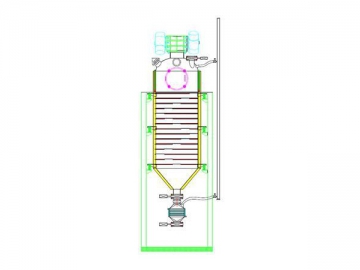

Load the products to be sterilized into the autoclave and securely close the door. Depending on the required product filling temperature, sterilization process water at the set temperature is injected from the hot water tank into the autoclave until it reaches the specified liquid level. A small amount of process water can also be introduced into the spray pipes through the heat exchanger.

- Heating and Sterilization

The circulation pump circulates process water on one side of the heat exchanger, spraying it continuously, while steam is introduced on the other side to heat the water to the set sterilization temperature. A diaphragm valve regulates steam flow to maintain stable temperatures. Atomized hot water is sprayed evenly over the product surfaces to ensure uniform sterilization. Temperature sensors and PID control functions precisely manage temperature fluctuations. - Cooling and Temperature Reduction

Once sterilization is complete, steam injection stops, the cold water valve opens, and cooling water flows into the other side of the heat exchanger to reduce the temperature of the process water and the products inside the autoclave. - Drainage and Completion

Any remaining water is drained, pressure is released through the exhaust valve, and the sterilization process is finished.

Leave Your Message

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos