Automotive Mold

Since the establishment, our company has been providing precision molds for all parts of the car. We have purchased large advanced production equipment and set up an engineering team of 60 people for producing the best automotive mold in the industry.

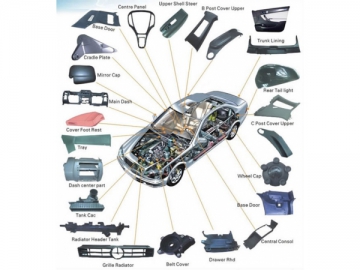

We provide molds for auto parts such as radiator, dashboard, door, inner cavity, inner decoration, etc. to companies like Toyota, GM, Nissan, Honda, VW, Volvo, BMW, Citroen, and Peugeot. These companies have strict requirements on the design, processing, and testing of automotive mold. This has urged us to adjust our standards to higher ones and also helped us form the habit of pursuing better quality.

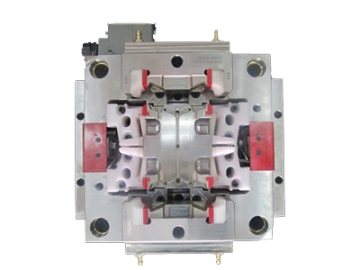

1. We adopt the industry's leading software: CAD/CAM, Solid Works, Pro/E, Power Mill, and Mold-Flow Simulation

2. DFM Report: we use mold flow software to analyze 3D mold flow chats and set the structure of the automotive mold. If necessary, adjustments can be made on 3D charts.

3. Design automotive mold according to the requirements of customers

Standard Mold Base: LKM

Standard Mold Accessories: Hasco, DME

Hot Runner: Mold Master, Yudoo, HRS

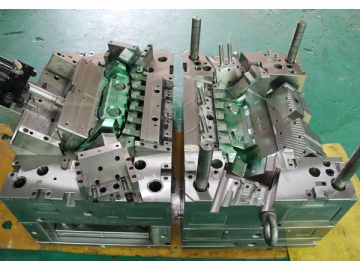

4. Mold manufacturing process

a. CNC Machine Center

b. WEDM

c. EDM

d. Fly Casting: there are two mold clamping machines and their clamping force is 1200 tons and 500 tons respectively.

e. Coordinate Measuring Machine: used to inspect workpieces after each processing step.

5. Customer specified mold surface treatment

a. Polishing

b. High gloss polishing or mirror polishing

c. Texturing, like VDI texture

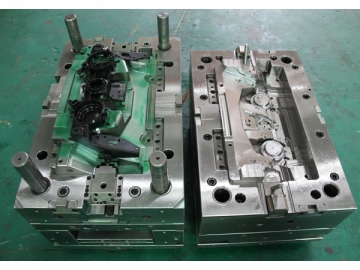

Kwok Fai specializes in making custom molds for automotive interior components. We have produced injection molds for A column, B column, C column, instrument panel, air outlet, door, seat, etc. These parts are the basic components of an automobile. They require higher surface quality and different injection molding materials as well as molding methods.

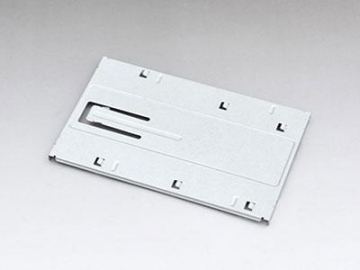

| Mold Type | Injection mold |

| Plastic Material | PP, ABS, PA GF, ASA |

| Cavity Number | 1 1, 1, 2, 4 , 8 |

| Steel Material Type | P20, H-12 |

| Runner System | 2 sets of HRS |

| Mold Service Life | 100000-1000000 shots |

| Mold Size | 100mm×100mm - 2500mm×4500mm |

| Mold Weight | 0.1T-40T |

| Gate Type | Valve gate, side gate, and sub gate |

| Molding Machine | various injection molding machines of 50-3000 tons |

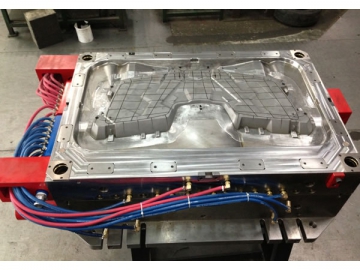

- SUV molds for export to USA

- SUV molds for export to USA

- Land Rover molds for export to UK

- Land Rover molds for export to UK

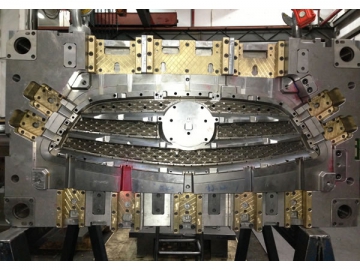

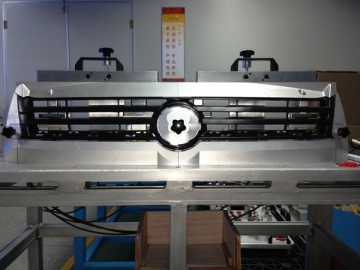

- Chinese grille mold

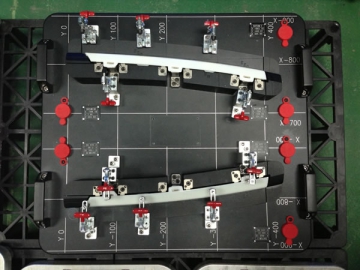

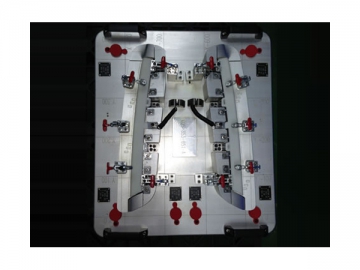

We not only provide auto moulds but also produce inspection tools for automotive molds. Accordingly, we can check the injection molded parts at any time to improve our mold production accuracy and avoid unnecessary waste. The inspection tools can be manufactured according to the requirements of customers. We have provided many domestic and foreign customers with professional inspection tools.

- Inspection tool for grille trim strip

for export to South Africa - Inspection tool for grille trim strip

for export to South Africa - Inspection tool for Honda grille

- Inspection tool for Honda grille

- Inspection tool for automobile

B-pillar