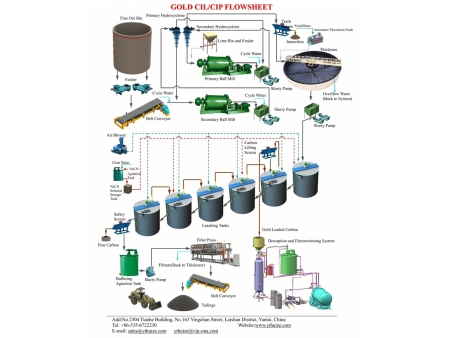

Gold CIP/CIL plant

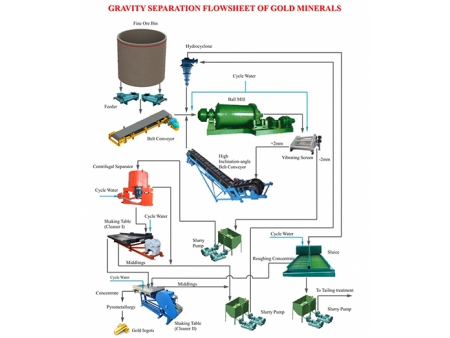

The gold ore is processed in the concentrator where it is crushed, screened, and ground to the proper mineral particle size. The slurry is then filtered to remove any sawdust and fiber before the thickener is applied to increase the concentration of the slurry before it undergoes cyanide leaching.

The CIP process begins with the leaching of slurry in several tanks using cyanide or other chemicals. After that, the solution is directed to an adsorption tank filled with activated carbon, in order to capture the gold.

The CIL (Carbon in Leach) process involves running leaching and adsorption operations in multiple tanks in parallel.

The gold loaded activated carbon is removed from the adsorption tank periodically, washed of mud and any other impurities on its surface, then transferred to the desorption workshop.

HZE's desorption-electrowinning system provides great efficiency and low energy consumption, with a cycle as short as 10 hours.

The gold mud undergoes a series of processes, such as pickling, separating other metals, washing, filtering, and drying. This allows it to be smelted and cast into gold ingots of high purity of at least 97%.

HZE proposed that the tailings should be processed through filtration and dehydration after the leaching and adsorption process are completed. The filtrate obtained from this process should be recycled into the production pool in the plant so that cyanide and other agents that remain can be reused. This would lower the amount of chemicals used and would provide a more eco-friendly atmosphere while at the same time stopping the release of any hazardous substances from the facility.