Hydraulic Tunneling Drilling Rig, KJ212

Request a Quote

Low profile drill rig

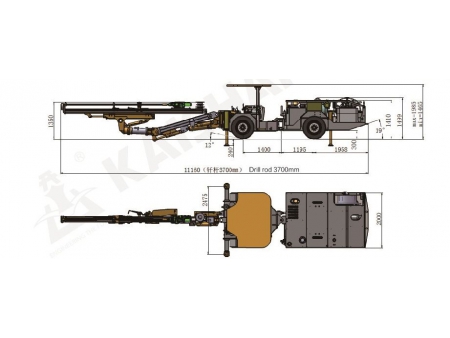

- Dimensions (L×W×H): 11160×2000×1465/1985mm

- Weight: 11000kg/Appr.11000kg

- Maximum gradeability: 20%(11°)

- Range of cross section: 2.5m-1.5m

KJ212 hydraulic tunneling drilling rig is a low profile drill rig able to drill vertical, inclined or horizontal holes. This tunneling jumbo is specially engineered for low-height tunnels with cross sections ranging from 3.5m×1.8m to 5m×4.8m, it can pass through a cross section of up to 2.5m×1.5m.

| Dimensions and weight | |||||||

| Length | 11160mm | ||||||

| Width | 2000mm | ||||||

| Height | 1465/1985mm | ||||||

| Weight | Approx.11000kg | ||||||

| Tramming speed on flat ground | 10km/h | ||||||

| Maximum gradeability | 20%(11°) | ||||||

| Safety protection | |||||||

| Noise level | < 100dB(A) | ||||||

| Lifting safety roof | Meet the requirements of FOPS and ROPS | ||||||

| Air and water system | |||||||

| Air compressor | 1×JN4 | Oil consumption of lubrication | 180-250g/h | ||||

| Capacity of air compressor | 0.5m³/min | ||||||

| Pressure | 6-8bar | Water pump | 1×CR3 | 1×CR5 | |||

| Shank lubrication device | Electronic pulse lubrication pump | Power | 1.5kW | 5.5kW | |||

| Air consumption of lubrication | 0.3m³/min | Capacity of water pump | 3m³/h | 6m³/h | |||

| Chassis | |||||||

| Diesel engine | Cummins QSB3.9-C80-31 60kW, 2200rpm | Steering mechanism | Articulated steering angle: ±35° | ||||

| Exhaust purification | Exhaust catalyzer | Parking braking | Multi-disc brake | ||||

| Drive system | Closed hydraulic system for four-wheel driving | Emergency braking | |||||

| Swing angle | Swing of rear axle: ±6° | Fuel tank | 30L | ||||

| Tires | 300-15 | ||||||

| Drilling system | |||||||

| Rock drill (drifter) | 1×HC50/R38 | 1×HC109/R38 | 1×HC95LM/R38 | ||||

| Impact power | 13kW | 18.8kW | 21kW | ||||

| Impact flow | 105L/min | 135L/min | 100-120L/min | ||||

| Impact pressure | 130bar | 135bar | 180bar | ||||

| Maximum rotary pressure | 150bar | 150bar | 210bar | ||||

| Impact frequency | 62Hz | 47Hz | 62Hz | ||||

| Torque | 325Nm | 780Nm | 764Nm | ||||

| Hole diameter | Ø32-76mm | Ø42-102mm | Ø42-102mm | ||||

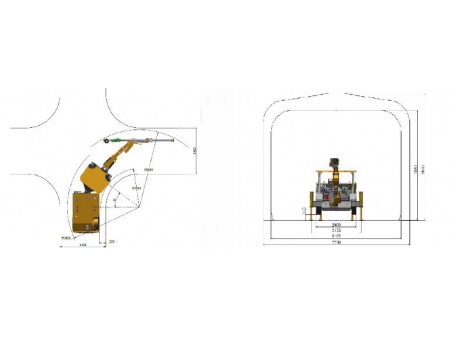

| Beam rotation | 360° | ||||||

| Feed extension | 1600mm | ||||||

| Model of drill boom | K20 | ||||||

| Form of drill boom | Automatic parallelism | ||||||

| Boom extension | 1200mm | ||||||

| Electric hydraulic power unit | |||||||

| Motor | 45kW | 55kW | 75kW | ||||

| Impact/Feed/Positioning | Variable displacement axial piston pump | ||||||

| Rotation | Gear pump | ||||||

| Filter fineness | 10µ | ||||||

| Hydraulic oil tank | 240L | ||||||

| Hydraulic cooler | Water cooler | ||||||

| Working voltage | 380V | ||||||

| Frequency | 50Hz | ||||||

| Starting method | Star/delta | ||||||

| Cable reel | 1×F440 | ||||||

| Length of reel cabling | 100m | 80m | |||||

| Cable specifications | 3×35 3G6 2×1.5 | 3×50 3G6 2×1.5 | |||||

- The hydraulic tunneling drilling rig is configured with medium/low pressure hydraulic drifters from Montabert. Hydraulic hoses and seals do not operate in high pressure conditions since the hydraulic drifter works under low oil pressure, thus resulting in prolonged service life, high reliability and less maintenance cost when compared to high pressure hydraulic drifter;

- The rock drill (drifter) uses stepped piston, which improves the efficiency of impact energy transfer from drill to rock, increases drilling speed, lowers the consumption of drilling tools while keeping the drill rig in good condition;

- Independently designed drilling rig boom uses Cartesian coordinate action principle to enable quick and simple drilling positioning since it can achieve that the feed beam is automatically parallel to the origin position; The robust drill boom offers optimum shaped coverage, with no blind spot for drilling holes, the boom can also execute cross-cut drilling and bolt hole drilling operations;

- Low-emission Cummins diesel engine paired with hydraulic four-wheel-drive transmission system is included in the hydraulic tunneling drilling rig, achieving stepless speed adjustment, high gradeability and fast walking speed; The exhaust purification device is equipped to greatly improve the underground working environment;

- Wet multi-disc service brake and spring-applied hydraulically released parking brake provide safe braking and high stability; In addition, emergency stop buttons at multiple points significantly enhance the safety during underground mining and tunneling operations;

- The compact structure of the tunneling jumbo makes steering more flexible, the powerful articulated chassis allows for steering angle of ±35° and rear axle swing angle of ±6°, enabling the drilling rig to easily pass through tunnels with a height down to 1.8m, and safely achieve right angle turns in a 3.5m wide tunnel;

- The spacious operating environment, lifting protective roof and considerably designed automatic functions of the low profile drill rig allow the operator to focus on drilling safely, quickly and accurately;

- Optimal layout of the drilling rig enables operator has a good visibility, and all parts at service points are securely protected, and accessible for easy maintenance;

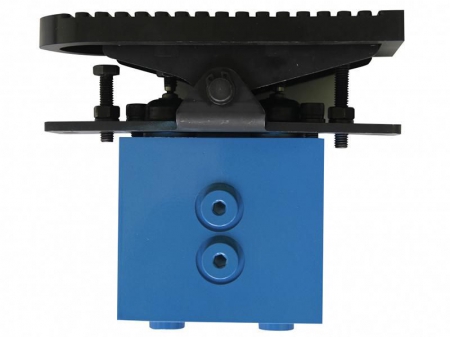

- The hydraulic tunneling drilling rig is equipped with the original power control valve block from Montabert, France, enabling it to feature automatic impact pressure adjustment, and anti-jamming function. This ensures smooth and accurate hole drilling during the operation.

- The drilling rig adopts auto-stop device and bottom hole debris clearing function, automatically stopping pushing and impacting after finishing the drilling process. The handle control can be used to blow out residue and water at the bottom of the hole, eliminating the need for manual cleaning and reducing operation cycle time.

- This drilling equipment comes with Kaishan brand energy-saving integrated direct-connected screw air compressor, offering smooth operation, easy maintenance, significantly saved energy and reduced pollution.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos