- Types

- Samples

- Specifications

- Features

- Details

Mid-frequency DC inverter spot welder converts three-phase AC power into DC power through rectification. The output of the MFDC inverter will be squares waves of electrical current at medium frequency of 1000HZ after controlled by the inverter circuit composed of IGBTs. Then it is transferred to primary transformer and the voltage is stepped down and rectified to provide a low-pulse DC current for welding the workpiece. The inverter adjusts the duty cycle of the IGBTs by feeding back the primary or secondary welding current, thereby achieving a constant current during the entire welding process.

Copper, aluminum, nickel, molybdenum, tungsten, manganese, gold, silver, and other non-ferrous metals

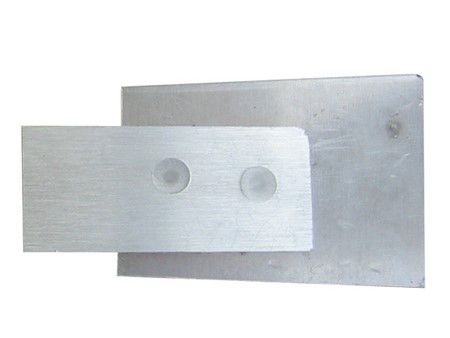

Low carbon steel plate welding, stainless steel plate welding, galvanized plate welding, aluminum plate welding, spot welding of wire, multiple spot projection welding, spot welding of high-strength steel in the automotive manufacturing industry, nut projection welding, as well as welding of copper wire, silver contact, and copper plate in the high and low voltage electrical industry.