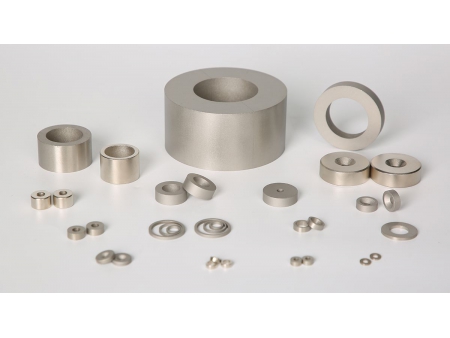

Samarium Cobalt Magnets-Sm 2 Co 17

Consisted of samarium and cobalt with an atomic ratio of 2:17

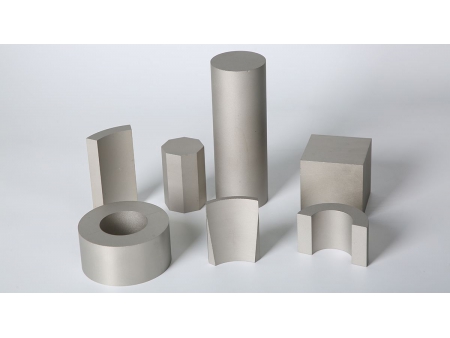

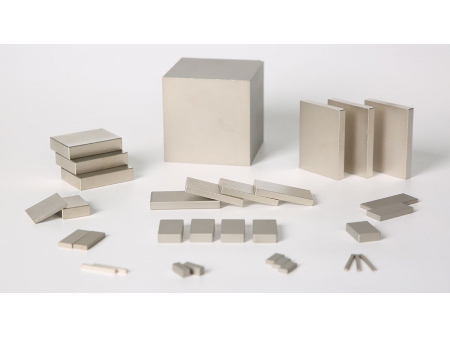

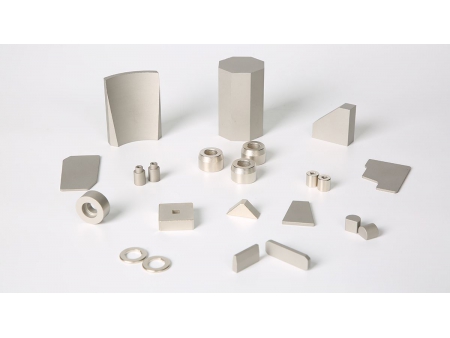

The 2:17 samarium cobalt magnets, also known as Sm2Co17 magnets, are a high-performance magnetic material made of samarium, cobalt, copper, iron, and zirconium through melting, grinding, pressing, sintering, and aging processes. With a maximum energy product ranging from 17-35 MGOe and a high working temperature between 250℃-500℃, Sm2Co17 magnets have excellent corrosion resistance and low temperature coefficient, making them ideal for various applications in aerospace, high-temperature motors, automotive sensors, magnetic drives, pumps, and microwave devices.

Although Sm2Co17 has excellent properties, it is brittle and not easily shaped into complex shapes or thin-walled structures like round disks or rings. During the production process, it may cause minor chipping, which is acceptable as long as it does not affect the magnet's functionality. We advise users to handle with care during assembly to avoid attracting iron or other magnetic materials, which could lead to breakage or injury.

Moreover, it is not easy to saturate and magnetize 2:17 magnets. If users need to magnetize the magnets themselves, it is essential to consider the magnetic field strength of the magnetizer and select the appropriate grade.

| Material | Grade | Br Remanence Br | Hcb Coercivity Force | Hcj Intrinsic Coercivity | (BH)max Maximun Energy | Tc Curie Temperature | Tw Max. Operating Temperature | Temperature Coefficient of Br α(Br) | Temperature Coefficient of Hcj β(Hcj) | ||||

| T | KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | ℃ | %/℃ | %/℃ | ||

| Sm2(CoFeCuZr)17 | YXG-24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥1990 | ≥25 | 175-191 | 22-24 | 800 | 350 | -0.035 | -0.20 |

YXG-26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1990 | ≥25 | 191-207 | 24-26 | 800 | 350 | -0.035 | -0.20 | |

YXG-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥1990 | ≥25 | 207-223 | 26-28 | 800 | 350 | -0.035 | -0.20 | |

YXG-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1990 | ≥25 | 223-239 | 28-30 | 800 | 350 | -0.035 | -0.20 | |

YXG-32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥1990 | ≥25 | 231-255 | 29-32 | 800 | 350 | -0.035 | -0.20 | |

YXG-33H | 1.12-1.16 | 11.2-11.6 | 845-890 | 10.6-11.2 | ≥1990 | ≥25 | 239-263 | 30-33 | 800 | 350 | -0.035 | -0.20 | |

YXG-22 | 0.93-0.97 | 9.3-9.7 | 676-740 | 8.5-9.3 | ≥1433 | ≥18 | 160-183 | 20-23 | 800 | 300 | -0.035 | -0.20 | |

YXG-24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥1433 | ≥18 | 175-191 | 22-24 | 800 | 300 | -0.035 | -0.20 | |

YXG-26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1433 | ≥18 | 191-207 | 24-26 | 800 | 300 | -0.035 | -0.20 | |

YXG-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥1433 | ≥18 | 207-223 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

YXG-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1433 | ≥18 | 223-239 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

YXG-32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥1433 | ≥18 | 231-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

YXG-33 | 1.12-1.16 | 11.2-11.6 | 845-890 | 10.6-11.2 | ≥1433 | ≥18 | 239-263 | 30-33 | 800 | 300 | -0.035 | -0.20 | |

YXG-35 | 1.16-1.2 | 11.6-12.0 | 868-908 | 10.9-11.4 | ≥1433 | ≥18 | 255-278 | 32-35 | 800 | 300 | -0.035 | -0.25 | |

YXG-26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 199-215 | 25-27 | 800 | 300 | -0.035 | -0.20 | |

YXG-28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

YXG-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

YXG-32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

YXG-24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8-12 | 183-199 | 23-25 | 800 | 250 | -0.035 | -0.20 | |

YXG-26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 8-12 | 199-215 | 25-27 | 800 | 250 | -0.035 | -0.20 | |

YXG-28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 207-220 | 26-28 | 800 | 250 | -0.035 | -0.20 | |

YXG-30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | 800 | 250 | -0.035 | -0.20 | |

YXG-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | 800 | 250 | -0.035 | -0.20 | |

| 2:17 Low temperature coefficient (SmEr)2(CoTm)17 | LTC(YXG-18) | 0.84-0.89 | 8.4-8.9 | 629-668 | 7.9-8.4 | ≥1433 | ≥18 | 135-151 | 17-19 | 840 | 300 | -0.001 | -0.25 |

LTC(YXG-20) | 0.89-0.94 | 8.9-9.4 | 660-708 | 8.3-8.9 | ≥1433 | ≥18 | 151-167 | 19-21 | 840 | 300 | -0.007 | -0.25 | |

LTC(YXG-22) | 0.94-0.98 | 9.4-9.8 | 692-740 | 8.7-9.3 | ≥1433 | ≥18 | 167-183 | 21-23 | 840 | 300 | -0.01 | -0.25 | |

| High temperature SmCo Sm2(CoFeCuZr)17 | HT400(YXG-26) | 0.99-1.04 | 9.9-10.4 | 740-812 | 9.3-10.2 | ≥1830 | ≥23 | 191-215 | 24-27 | 850 | 400 | -0.035 | -0.12 |

HT450(YXG-24) | 0.96-0.99 | 9.6-9.9 | 724-772 | 9.1-9.7 | ≥1830 | ≥23 | 175-199 | 22-25 | 850 | 450 | -0.035 | -0.12 | |

HT500(YXG-22) | 0.93-0.97 | 9.3-9.7 | 708-756 | 8.9-9.5 | ≥1830 | ≥23 | 160-183 | 20-23 | 850 | 500 | -0.035 | -0.12 | |

| Calculation of Theoretical Values of Br and Hcj at High Temperature | The temperature coefficients of remanence Br and intrinsic coercivity Hcj are measured at 20°C to 150°C, only for reference. Theoretical calculation formula (T1 = room temperature (usually 20℃), T2=high temperature): Br@T2=Br@T1-[(T2-T1)*α(Br)*Br@T1] Hcj@T2=Hcj@T1-[(T2-T1)*β(Hcj)*Hcj@T1] Taking YXG-28H, Br=1.03T, Hcj=1990KA/m as an example, the theoretical value at 150℃ is calculated as follows: Br@150℃=1.03-[(150-20)*0.035%*1.03]=0.9831T Hcj@150℃=1990-[(150-20)*0.2%*1990]=1472KA/m | ||||||||||||

| Remark: 1) There will be a slight test error during the magnetic performance test, but the error rate is less than 1%. Because the roughcast are not fully inspected, the performance indicators of all grades will have individual deviations. Take the YXG-30 grade as an example, Br=10.8-11.0KGs (of which there may be less than 5% of the performance range between 10.75-11.04KGs). 2) The maximum working temperature has a lot to do with the specific working environment, load coil and other factors. 3) With the improvement of technology, the performance index may be changed, please refer to the latest version of NGYC property sheet. | |||||||||||||

| Item | Unit | Sm2Co17 Magnet |

| Density (D) | G/Cm3 | 8.4 |

| Curie Temperature (Tc) | K | 1100 |

| Vickers Hardness (Hv) | MPa | 550-600 |

| Compressive Strength (δc) | MPa | 800 |

| Resistivity (ρ) | Ω.Cm | 8~9×10-5 |

| Bending Strength (δb) | Mpa | 130-150 |

| Tensile Strength (δt) | Mpa | 35 |

| Coeff. of Thermal Expansion (α) | (10-6/℃) | ∥ 8 ⊥11 |

Please note that the above values are for reference purposes only and should not be used as the sole basis for material acceptance or rejection.