Vertical Form Fill Seal Machine with Auger Filler, L4T620-FT

Specially designed for powdered products, the vertical form fill seal machine is equipped with an auger filler, screw feeder and main packer. It’s ideally suitable for the packaging of powdered products featuring 100 mesh. Auger filler and hopper of screw feeder's capacity can be customized according to the client's requirement.

- Production rate: up to 55 packages per minute.

- Bag format: quad seal bag, quad seal bag with a punching hole.

- Application: powdery products, such as flour, soy milk powder, coffee powder, powder laundry detergent, etc.

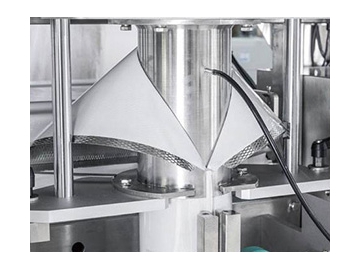

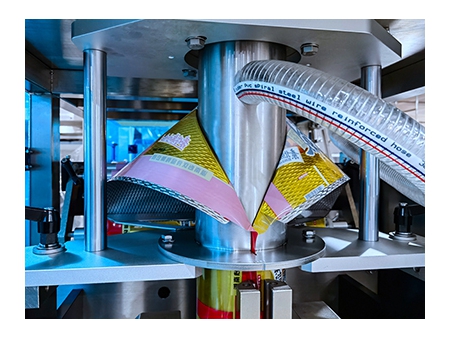

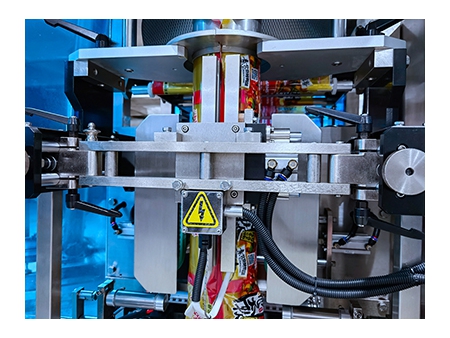

Bag forming unit

Bag forming unit Powder dosing unit

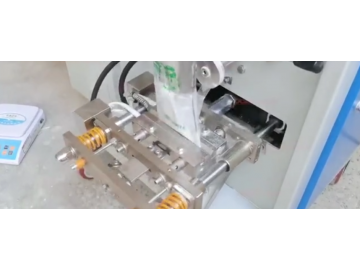

Powder dosing unit Horizontal sealing

Horizontal sealing Vertical sealing

Vertical sealing

The products are measured by the screw rotation numbers, which are fast and precise with an error range within ±1g. The capacity varies from 30 to 50L depending on the machine type.

The color code photo eye and the transport system are sensitive to the materials so that they can be filled and supplemented in time. The open-type feeding hopper is easy to clean.

The packaging machine is controlled by Panasonic servo motor and a single/double film drawing system is adopted to ensure the film transporting stability and bag forming smoothness. The SMC/Airtac air cylinder helps to improve bag sealing property and reduce failure rate.

External film unwind apparatus simplifies film changeover. Standard code printer uses intermittent ribbon coding to ensure the color fastness of the printed date.

PLC control, Panoramic driver and Wienview touch screen feature simple operations and are sensitive to touch. The operation system supports a variety of languages, including English, Russian, French, Spanish, Arabic, Korean, Persian, etc.

Products are conveyed by screws and the hopper can vibrate to prevent materials build-up. After receiving the signal from color code induction system, the material will be fed automatically, making it easy to operate and control.

The feeding process is totally sealed to minimize dust output. The capacity of the vibrating hopper is 80-150L and the diameter of the feeding tube is 100-114mm, which vary among different machine models.

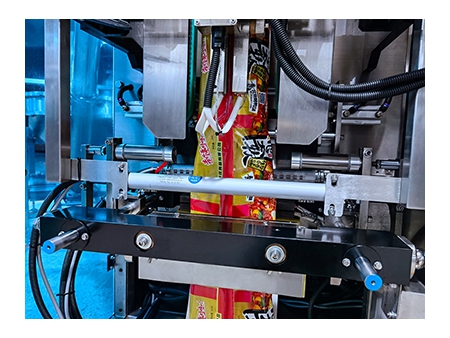

The finished bags are conveyed to the platform by screws, which are driven by micro motors. The conveying capacity is up to 60-80 bags per minute with higher smoothness and lower noise.

The conveyor belt can be customized to fit your specific requirements. For example, PVC belt, stainless steel chain conveyor or PVC chain conveyor is optional based on the characteristics of product materials.

| Model | SK-L4T620-FT |

| Dispensing capacity | 800-1500g |

| Bag width range | front side width 90-190 mm lateral side width 50-120 mm seal width 5-10 mm |

| Bag length range | 100-400 mm |

| Speed | 5-55 bags/min |

| Material type | various film laminates |

| Machine Dimensions | L4500*W1300*H3200 mm |

| Machine weight | 1200kg |

| Packaged wooden cases | 5 cases/8-9 m³ |

| Air consumption | 0.65mPa, 2.5m³/min |

| Power supply | 220V 50/60HZ 3kW |

If you are interested in our vertical form fill seal machine with auger filler, you are welcome to contact us for more details.