Hydraulic Tunneling Drilling Rig, KJ311

Request a Quote

Computer-assisted drilling rig

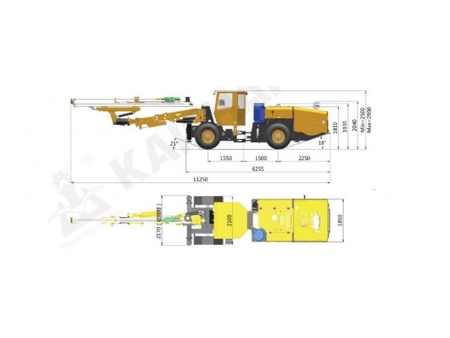

- Dimensions (L×W×H): 11250×1850×2500/2900mm

- Weight: 12500kg

- Maximum gradeability: 25%(14°)

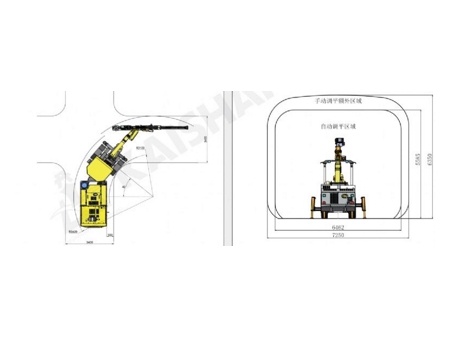

- Range of cross section: 12-35m²

This hydraulic tunneling drilling rig is computer-assisted intelligent tunneling equipment suitable for blast hole drilling in hard rock mining and tunneling with cross sections of 12-35m².

| Dimensions and weight | Drilling system | |||||

| Length | 11250mm | Model of rock drill (drifter) | HC50/R38 | HC95SA/R38 | HC95LM/R38 | |

| Width | 1850mm | Impact power | 13kW | 20kW | 24kW | |

| Height | 2500/2900mm | Impact pressure | 130bar | 165-200bar | 180-200bar | |

| Weight | 12500kg | Max rotary pressure | 150bar | 210bar | 210bar | |

| Tramming speed | 10km/h | Impact frequency | 62Hz | 62Hz | 62Hz | |

| Maximum gradeability | 25%(14°) | Torque | 325Nm | 597Nm | 764Nm | |

| Safety protection | Hole diameter | 32-76mm | 42-102mm | 42-102mm | ||

| Noise level | <100dB(A) | Beam rotation | 360° | |||

| Lifting safety roof | FOPS&ROPS | Feed extension | 1600mm | |||

| Air and water system | Model | K26F | ||||

| Air compressor | 1×JN4 | Form of drill boom | Automatic parallelism | |||

| Capacity of Air compressor | 0.5m3/min | Boom extension (matching) | 1200mm | |||

| Pressure | 6-8bar | Electric hydraulic power unit | ||||

| Device of shank lubrication | Electronic pulse lubrication pump | Motor | 45kW | 55kW | 75kW | |

| Air consumption of lubrication | 0.3m3/min | Impact/feed/positioning | Axial variable displacement piston pump | |||

| Oil consumption of lubrication | 180-250g/h | Rotation | Gear pump | |||

| Water pump | 1×CR3 | 1×CR5 | Filter fineness | 10μ | ||

| Power | 1.5kW | 5.5kW | Hydraulic oil tank | 240L | ||

| Capacity of water pump | 3m3/h | 6m3/h | Hydraulic cooler | Water cooler | ||

| Chassis | Working voltage | 380V | ||||

| Diesel engine | 60kW,2200rpm | Frequency | 50Hz | |||

| QSB3.9-C80-31 | Starting method | Star/delta | ||||

| Exhaust purification | Exhaust catalyzer | Cable reel | 1×F440 | |||

| Drive system | Four-wheel drive system with wet axle | Length of reel cabling | 100m | |||

| 80m | ||||||

| Swing angle | Swing of rear axle±6° | Cable specifications | 3×35 3G6 | 3×50 3G6 | ||

| tires | 11.00-20 | / | / | / | / | |

| Steering mechanism | Articulated steering angle: ±40° | / | / | / | / | |

| Parking braking | Wet multidisc brake of reducer | / | / | / | / | |

| Travelling braking | Two-circuit hydraulic brake | / | / | / | / | |

| Fuel tank | 60L | / | / | / | / | |

- The hydraulic tunneling drilling rig has functions of automatic hole positioning, automatic control of rock drilling process, centralized lubrication, fault alarm and automatic shutdown; In addition, the drilling parameters will be displayed in real time so that operator can realize remote control of the drilling rig;

- With password verification, it is possible to download and store the operating parameters, which can be used as basis for the modification and improvement of the hydraulic tunneling drilling rig;

- A robust universal boom provides optimum shaped coverage, and the powerful articulated chassis with four-wheel-drive transmission ensures stable and safe maneuvering with high flexibility in small and narrow construction tunnels;

- KJ311E hydraulic tunneling drilling rig is equipped with the French Montabert imported medium and low pressure high-frequency hydraulic rock drill, and a stepped piston for enhanced reliability and lower maintenance costs.

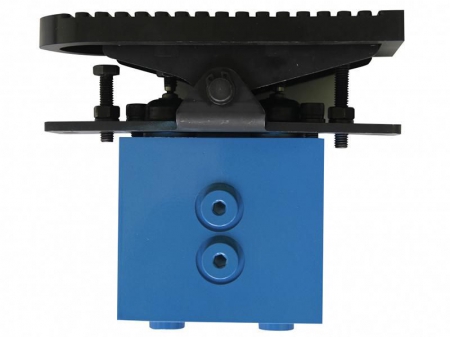

- The drilling rig is equipped with the original power control valve block from Montabert, France, enabling it to feature automatic impact pressure adjustment, and anti-jamming function. This ensures smooth and accurate hole drilling during the operation.

- It utilizes a newly designed Cartesian coordinate linear motion drilling arm to maintain automatic parallelism with the initial position, facilitating quick and convenient positioning for drilling.

- The hydraulic drilling equipment adopts auto-stop device and bottom hole debris clearing function, and it will automatically stops pushing and impacting at the end of the drilling process, reducing operation cycle time.

- Kaishan brand energy-saving integrated direct-connected screw air compressor is equipped in the hydraulic drilling rig, offering smooth operation, easy maintenance, significantly saved energy and reduced pollution. This makes a great contribution to improving the working environment, and protecting human health.

- The drilling equipment is equipped with a Cummins diesel engine, and walking brake adopts a dual-circuit multi-disc wet brake system, complemented by a multi-disc parking brake system, providing double guarantee for the braking of the drilling rig.

- Spacious working space ensures good driver visibility, and the drilling rig is equipped with a liftable safety roof and a series of automatic functions.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos