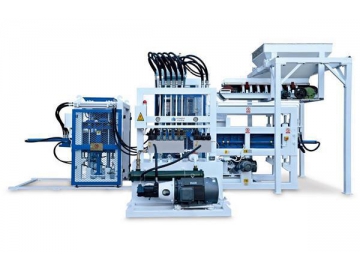

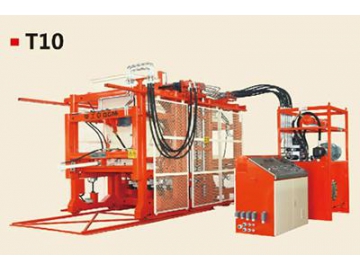

Hydraulic Concrete Block Making Machine, QT4000

Technical Parameters of QT4000 Hydraulic Concrete Block Making Machine

| Vibration frequency | 3800-4500 times/sub | |||

| Total weight | 9000kg | |||

| Installed capacity | 22kW | |||

| Cycle time | 15-20s | |||

| Rated pressure | 31.5Mpa | |||

| Exciting force | 4000kN | |||

| Plate specification | 920×580×18-20mm | |||

| Molding way | Vibration extrusion forming | |||

| Stacker capacity | 3.7kW | |||

| Block | Hollow block | Solid brick | Pavement brick | |

| Picture |  |  |  |  |

| Size | 390×190×190 | 238×113×51 | 230×115×60 | 200×100×60/80 |

| Molding blocks | 4pcs/mold | 18pcs/mold | 12pcs/mold | 16pcs/mold |

| Molding cycle | 18-25s | |||

| Per hour production | 800pcs/1h | 3600pcs/1h | 2400pcs/1h | 3200pcs/1h |

| Class production | 6400pcs/8h | 28800pcs/8h | 19200pcs/8h | 25600pcs/8h |

| Excitation frequency | 50~60Hz | |||

| Block height | 50~200mm | |||

| Power of main motor | 22kW | |||

| Weight | 9000kg | |||

**Note: The above parameters are for reference only. Modifications and upgrades are available. Contact us directly for details.

The QT4000 hydraulic concrete block making machine is a new hydrostatic block machine we recently launched. This machine is a fully automatic hydraulic block forming machine that can be used nearly anywhere as it works quietly.

Features

1. The hydraulic concrete block making machine is equipped with high and low pressure pumps and prefill valves, giving the machine a higher forming efficiency. The machine forms the block without shaking, giving the finished blocks a higher forming accuracy.

2. After the block forming process is complete, the concrete block making machine can stack the blocks on site, saving space and labor.

3. The hydraulic concrete block making machine integrates mechanical, electrical and hydraulic technologies automatically.

4. The PLC control system displays the working condition of the machine and will alert operators to failures or alarms when they arise. The system also allows for fault diagnoses and recovery.

5. This block making machine automatically and efficiently feeds and arranges raw materials.

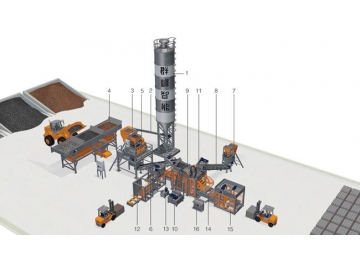

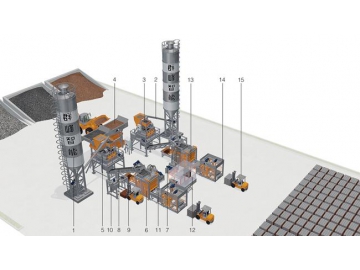

Applications

The hydraulic concrete block making machine is used to produce different sized color pavement blocks, curbstones, precast components for high-speed rail cable troughs, landscaping products and more. This multi-functional concrete product machine is also suitable for production of sintered wall building blocks and other bricks made from solid waste, such as high-content coal fly ash, coal gangue, cinders, construction waste, household waste burning residues, waste clay and more.

Pictures of Details

- Electrical control cabinet

- Material feeding system

- Mold brush

- Bearing

For more molds and samples, please click ""