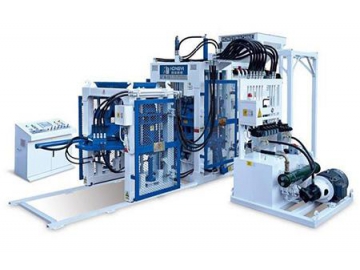

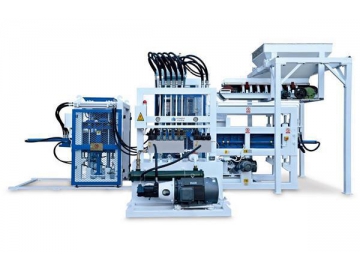

Concrete Block Making Machine, QT8-15

Technical Parameters of QT8-15 Concrete Block Making Machine

| Vibration frequency | 3800-4500 times/sub | ||||

| Total weight | 11500kg | ||||

| Overall dimension | 9800×3600×2800mm | ||||

| Installed capacity | 31.7kW | ||||

| Cycle time | 15-20s | ||||

| Rated pressure | 31.5Mpa | ||||

| Exciting force | 95kN | ||||

| Plate specification | 940×860×25mm | ||||

| Molding way | Vibration extrusion forming | ||||

| Stacker capacity | 3.0kW | ||||

| Block | Hollow block | Solid brick | Porous brick | Pavement brick | |

| Picture |  |  |  |  |  |

| Size | 390×190×190 | 240×115×51 | 240×115×90 | 200×100×60/80 | 250×250×60 |

| Molding blocks | 8pcs/mold | 42pcs/mold | 21pcs/mold | 24pcs/mold | 8pcs/mold |

| Molding cycle | 15~20s | 20~30s | |||

| Per hour production | 1440pcs/1h | 9000pcs/1h | 3780pcs/1h | 4320pcs/1h | 1440pcs/1h |

| Class production | 11520- 15360pcs/8h | 60480- 80640pcs/8h | 30240- 40320pcs/8h | 34560pcs/8h | 11520- 15360pcs/8h |

| Excitation frequency | 50~60Hz | ||||

| Block height | 50~200mm | ||||

| Power of main motor | 31.7kW | ||||

| Machine size | 9800×3600×2800mm | ||||

| Machine weight | 11500kg | ||||

**Note: The above parameters are for reference only. Modifications and upgrades are available. Please contact us directly for more information.

Characteristics

1. The QT8-15 concrete block making machine has a shock-proof, heavy duty structure made from high density cast steel.

2. The fully automatic brick forming machine is equipped with an electrical system that consists of the German Siemens PLC control system and a touch screen. The PLC control system has safe logic control and troubleshooting functions.

3. A hydraulic system on the multi-functional concrete block making machine is equipped with double high dynamic proportional valves that can automatically adjust the oil flow and oil pressure. The double-valve hydraulic system works with a 4 rod guiding system and the long guide bushing guarantees the precise movement between the tamper head and the mold.

The rubber parts, brushes, bolts, springs and bearings are more easily worn than other components during the working process of the concrete block making machine. Due to that, the machine needs to be carefully maintained. To assist with that, we supply various spare parts for replacement along with the concrete block production equipment. You can also get these parts on local markets. If concrete block machinery parts aren't available in your area, please contact us and we will supply them as quickly as possible. Our machine comes with a one-year warranty, and problems or requirements are easily met, simply contact us.

Pictures of Details

- Detail of main machine

- Mould brush

- Pigment mixer

- Screw

For more molds and samples, please click ""