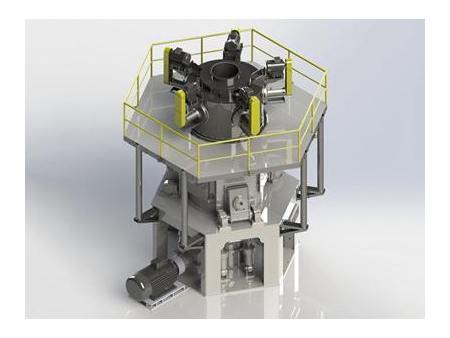

Ultrafine Powder Vertical Roller Mill

Application

VSLM series vertical ultrafine powder vertical roller mill can be widely applied to processing of ultrafine powder of non-metallic mineral such as calcite mineral, marble mineral, limestone mineral, barite, talc, dolomite mineral, wollastonite mineral, potash feldspar, pyrophyllite mineral, fluorite, zeolite, silica, gypsum, mica, kaolin, bentonite, bauxite, illite, vermiculite, sepiolite, ceramics, aluminum hydroxide, magnesium hydrate, furnace slag and steel slag.

Parameters of vertical roller mills of different types (take calcite mineral as the grinding material)

| Less than 2μm=33% production rate(t/h) | 6~8 |

| Less than 2μm=40% production rate(t/h) | 4~6 |

| Less than 2μm=50% production rate(t/h) | 2~3 |

| Power of the main body(KW) | 160 |

| Power of the fan(KW) | 132 |

| Power of the air compressor(KW) | 30 |

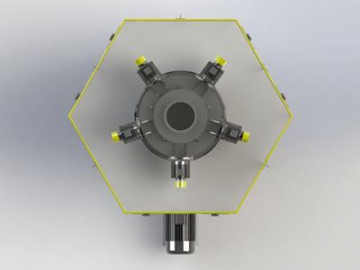

| Power of the classifier wheels(KW) | 15×4 |

| Power consumption(main body, fan, classifier) (KW/H) | 38 |

| Less than 2μm=33% production rate(t/h) | 11~13 |

| Less than 2μm=40% production rate(t/h) | 8~9 |

| Less than 2μm=50% production rate(t/h) | 5~6 |

| Power of the main body(KW) | 220 |

| Power of the fan(KW) | 185 |

| Power of the air compressor(KW) | 37 |

| Power of the classifier wheel(KW) | 15×5 |

| Power consumption(main body, fan, air compressor, classifier) (KW/H) | 32 |

| Less than 2μm=33% production rate(t/h) | 12~14 |

| Less than 2μm=40% production rate(t/h) | 11~13 |

| Less than 2μm=50% production rate(t/h) | 7~8 |

| Power of the main body(KW) | 250 |

| Power of the fan(KW) | 200 |

| Power of the air compressor(KW) | 37 |

| Power of the classifier wheel(KW) | 18.5×5 |

| Power consumption(main body, fan, air compressor, classifier) (KW/H) | 33 |

| Less than 2μm=33% production rate(t/h) | 14~16 |

| Less than 2μm=40% production rate(t/h) | 12~14 |

| Less than 2μm=50% production rate(t/h) | 9~10 |

| Power of the main body(KW) | 280 |

| Power of the fan(KW) | 220 |

| Power of the air compressor(KW) | 45 |

| Power of the classifier wheel(KW) | 18.5×6 |

| Power consumption(main body, fan, air compressor, classifier) (KW/H) | 33 |

Product characteristics

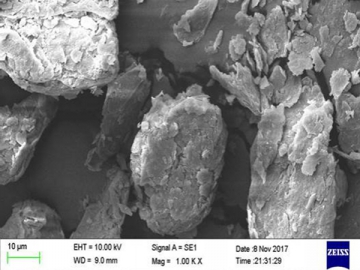

1. VSLM series vertical roller mill is equipped with turbine air classifier. Its products have a wide range of optional size. The content of 2μm fine powder is 10%-60% (tested by Malvern 2000 particle size laser analyzer), D97 from 6μm to 45μm.

2. The size range of finished powder is small. We can adjust and control the distribution of the powder according to the demands of our customers.

3. The vertical grinding mill is equipped with drying system itself. So the comprehensive moisture of the materials which go into the vertical grinding mill can reach 20%.

4. The added value of the powder is high. It can be used in many fields such as papermaking, paint, rubber, artificial granites, plastic masterbatch, piping material, PVC calendering film, wires and cables, baby diapers, non-woven fabrics, toothpaste, food and pharmacy.

5. We adopt advanced design of production line. The power consumption of our vertical ultraultrafine powder vertical roller mill is lower and the production is higher. Compared with domestic equipment of the same type, our output has raised by 10%~30%. Compared with ball mill, the power consumption of our products has lowered by 30%~60%.

6. We adopt powder grinding equipment technology. After being improved, the roller and Grinding table can work under low vibration. It produces less noise. The tested noise level is about 70 decibels in one meter area of the mill.

7. All the operations are conducted under fully closed cycle system. There is little dust pollution. The production environment is clean, hygienic and more environmentally-friendly.

8. VSLM series grinding mill adopts imported high chromium rare earth alloy steel which has good quality and is wear resistant. It can be used to grind materials with high hardness such as waste ceramic tiles.

9. We adopt fully automatic PLC online control. The parameters can be displayed real time by flash which realizes artificial intelligence to a large extent.

10. Any disorder of the equipment can be detected online through remote monitor and control which feature higher efficiency and speed.

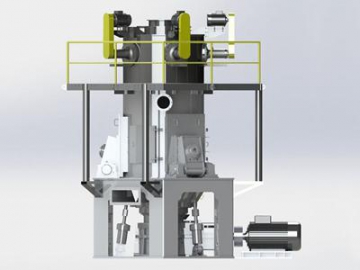

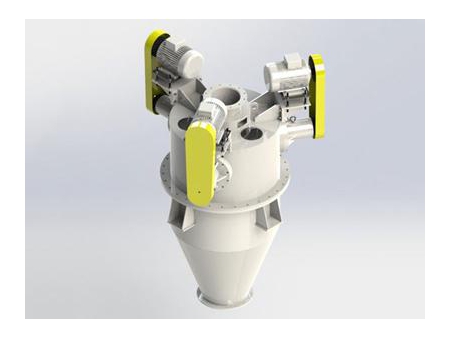

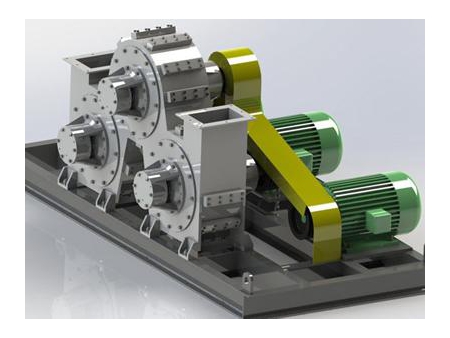

Working principal

The main motor drives the grinding table by reduction gear box. The materials go into the mill by screw conveyor. Then they fall to the middle of the grinding table under gravity. At the same time the air flow produced by the fan goes into the mill. Under the centrifugal force, the materials move from the middle to the edge of the grinding table. When it passes through the rolling passage of the grinding table, it's compacted by the roller. The large materials are crushed directly and the small materials are extruded to form a special layer to undergo intergranular comminution. After being grinded, the materials continue to move to the edge of the grinding table until they are taken upward by the strong air flow of the annular groove at the outer of the grinding table. Those materials which are more coarse would fall in the grinding table under the force of gravity and be grinded again while those smaller ones would rise in the air flow to the classifying system to be classified. Under the effect of the rotor blades of the classifier, the coarser particles would be stricken back to the grinding table to be grinded again. Only those which are qualified would be taken out of the classifying system by the negative pressure air flow and taken into the dedust equipment. After being collected by the powder collecting machine, they become finished products. Besides, the materials and other particles which have larger sizes would fall into the lower cavity of the mill. Then they are scraped to the slagging mouth and discharged which ensures the quality of the products effectively. By adjusting the pressure of the hydraulic pressure system, the pressure of the roller can be changed. So it can handle raw materials of different hardness to a certain extent. The speed of the rotator of the classifying system of classifying wheels can be adjusted. So qualified products of different types are available.

Vsunny offers various industrial ultrafine powder vertical roller mill, and the complete equipment line that is for mineral crushing, grinding, classifying and separation. We can provide custom milling equipment and solutions in client needs.