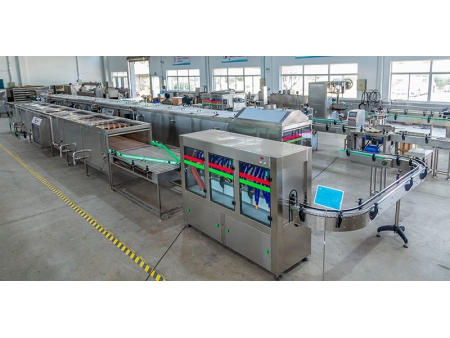

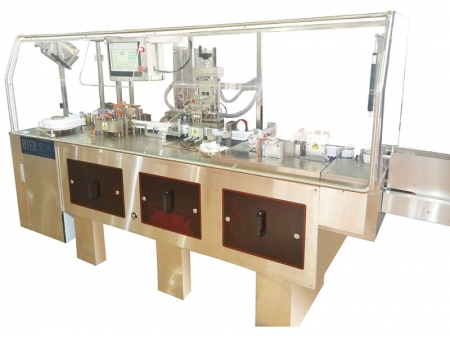

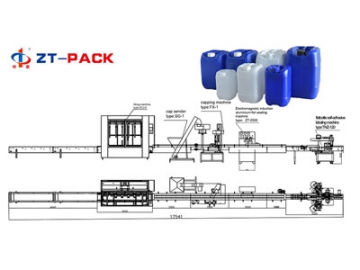

Inline liquid filling equipment and packaging machinery

Our liquid filling line stands as an automatic system that offers a comprehensive solution for the filling and packaging of a wide array of liquids. Engineered for efficiency, it integrates an advanced conveying system, filling system, sealing system, and final packaging in one seamless flow. We offer customizable designs tailored to your configuration and parameter preferences.

-

- Filling speed:

- 200-2400bph

-

- Filling accuracy:

- ≦±1﹪

-

- Filling heads:

- 2/4/6/8 heads (customizable)