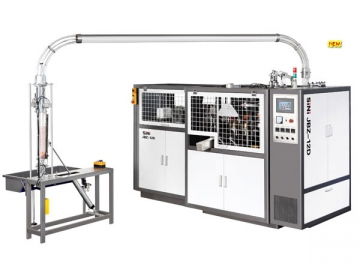

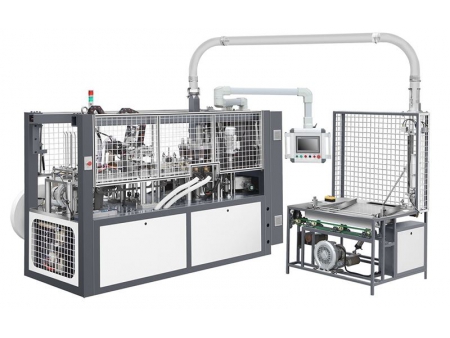

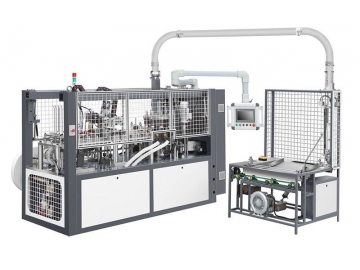

JBZ-12D Paper Cup Forming Machine

This JBZ-12D paper cup forming machine is a kind of intelligent middle speed product, which is upgraded from the low speed machine. Its entire body of steel sheet and the spray lubrication system enable the machine to work at normal operation state for a long time.

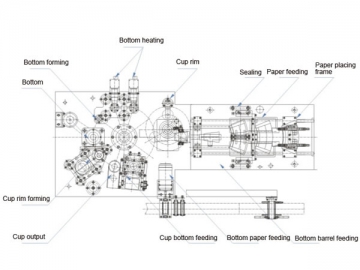

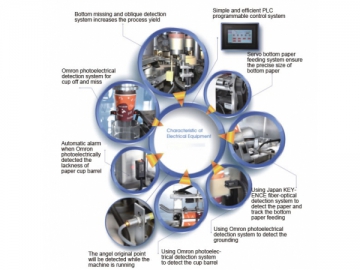

Driven by the advanced high precision cylindrical cam, the machine makes use of gear transmission to ensure precise forming performance of each station. As for the bottom paper feeding, the specialized servo tracking system will get the precise size of the cup bottom, saving the raw material effectively. Moreover, the cup bottom is heated twice without flame via the Switzerland Leister heater.

For every process in the production, we utilize the Japanese Omron photoelectric detection and give the corresponding reports. Through the human-machine interface, the paper cup forming machine is capable of remaining long term operation under the control of PLC system. With the reasonable setting, the cup collection platform with automatic counting function is the perfect replacement of human labor.

Main machine and control cabinet can be opened freely for easy maintenance and operation.

There are 2 sets of imported air heaters from Switzerland mounted for keeping stable heating temperature.

Automatic oil spraying lubrication system restricts the machine to start if the oil channel is blocked or lack of oil.

Combination of cylindrical cam drive with gear drive makes the machine run stably at high speed.

Advantages

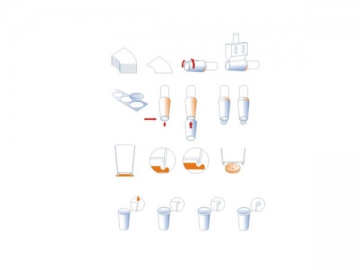

1.The machine is designed to assort paper automatically while absorbing the materials.

2. If the paper is in short, it will alarm automatically.

3. If the machine detects that pieces of paper is not absorbed or blocks the machine, it will shut down.

4. It offers automatic track on conveying paper and feeding paper.

5. While gluing the side seal, the paper cup forming machine will stop if there is no paper at all.

6. The ultrasound probe is used to detect the paper feeding situation. If there is no paper, the machine will halt.

7. When it detects that there is no cup barrel in the adhesion of side seal, the machine will stop, too.

8. Our paper cup forming machine adopts the robot hand to supply the silicon oil. It supports automatic bottom paper shaping.

9. If no bottom paper or inclined bottom paper is servo conveyed, the machine will stop.

10. The detection of the drop of the finished cup will lead to the stop of the machine.

11. When it detects that the finished cup misses the inspection, the machine will have a halt.

12. Users can set any station among the 18 optional stations to filter and sort the cup that leads to the stop of machine.

13. There are 2 sets of Switzerland heaters for controlling the temperature of the bottom. If the forming temperature is not consistent with the set temperature, the machine can't be started.

14. When the machine stops for 5 minutes, it will switch to the energy saving mode automatically.

15. Our paper cup forming machine supports manually stop when the cup is blocked or unloaded on the cup collection platform.

16. Through the setting on the human-machine interface, the machine offers automatic stop if there is no cup collected onto the cup collection platform.

17. The control angle of the encoder allows random adjustment.

18. The machine is installed with the liquid level switch for stop. The equipment will be separated automatically after shutting down.

19. The main engine and the control cabinet can be opened arbitrarily so that it is convenient for maintenance and operation.

20. Under the drive of cylindrical cam with the gear transmission, the paper cup forming machine keeps stable operation at high speed.

21. Equipped with the automatic central spray lubrication system, the machine can't be started if it is lack of oil or the oil pipeline is blocked.

| Model | JBZ-12D |

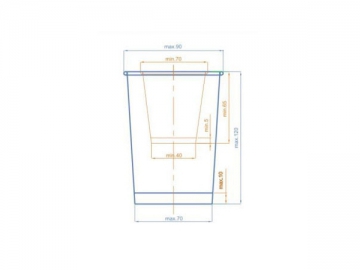

| Paper Cup Dimension | 6-12ounce (Outer diameter of cup rim 70-90mm, outer diameter of cup bottom 40-70mm, height of cup 65-120mm, depth of cup bottom 5-10mm) |

| Capacity | 60-75pcs/min |

| Maim Motor Power | 2.2kw |

| Electric Heating Power | 8kw |

| Total Power | 15kw |

| Air Supply | 0.4m³/min, 0.5MPa |

| Applicable Paper | 190-350g/m² (Single or double face laminated with PE film) |

| Weight | 3100kg |

| Overall Size | 2950mm×1400mm×2000mm |

| Cup Collection Device Size | 1050mm×850mm×1950mm |

| Note: The thickness of the laminated PE film on the paper is not lower than 15g/m². | |