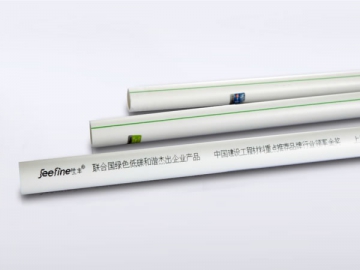

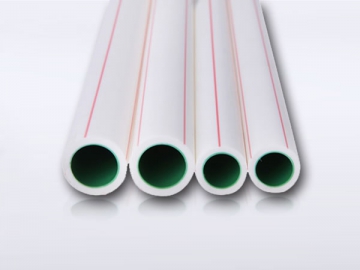

PPR Pipe

Application

The PPR pipe we produce can be used in the following fields:

1. Hot and cold water pipe system for residential houses

2. Delivery and discharging pipes for industrial water and chemical substances

3. Pure water and drinking water pipeline

4. Delivery system for beverage and medication production

5. Compressed air pipe

6. Pipe used for industry and agriculture

Features

1. Non-toxic, Hygienic and Eco-friendly

Our PPR pipe is made of polyolefin material whose molecule is composed of only carbon element and hydrogen element. Therefore, our polypropylene pipe is of high hygiene grade and will not cause any pollution to the natural environment in the process of production, construction and using. This product is a green building material which can be reused.

2. Corrosion Resistance

Except for a few kinds of oxidizing agents, our PPR water pipe is resistant to most of chemicals and will not become rusty, corroded or contaminated by bacteria. Thanks to its high corrosion resistance, our PPR pipe will not cause rust on the sink or bath and is able to avoid blocking caused by the corrosion of pipeline.

3. No Scaling and High Flow Capacity

Our PPR composite pipe dose not scale since is has smooth inner wall. With friction resistance coefficient of only 0.007, our product has high flow capacity.

4. High Temperature and High Pressure Resistance

The vicat softening temperature of our plastic tube is 131.3℃. Its maximum short-time working temperature is 95℃ and its long-term working temperature is 70℃. The designed working pressure of our water tube is 2.5Mpa.

5. Thermal Insulation and Energy Saving

The plastic PPR pipe we produce has heat conductivity coefficient of 0.24W/.℃, which is only 1/200 that of steel pipe. Therefore our products can achieve excellent heat preservation and energy saving effects if they are used as hot water pipelines.

6. Light Weight

The weight of the PPR pipe produced by our company which is a professional pipe supplier is only 1/7 that of metal tube.

7. Nice Appearance

Our product comes with elegant appearance and is in soft color. The inner and outer walls of our water tube are smooth, making for low flow resistance.

8. Easy Installation

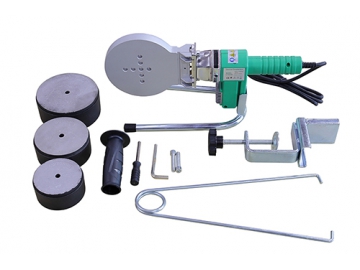

Our PPR water pipes can be installed in just a few seconds through hot melting connection technology. Nickel-plated metal inserts can be used to connect our plastic water pipe to metal pipes or the faucets.

9. Long Service Life

Our product has a service life of over 50 years used under normal conditions.

| Physical And Chemical Properties Of PPR Pipes | ||||||

| Items | Test Temperature | Test Parameter | Sample Parameters | Index | ||

| Test Time (h) | Hydrostatic stress (Mpa) | |||||

| Longitudinal shrinkage rate | 135 ± 2 | en ≤ 8mm 1 8mm ≤ en ≤ 16mm 2 en ≤ 16mm 3 | - | 3 | ≤ 2% | |

| Simple supporting beam impact test | 0 ± 2 | - | 10 | Percentage of breakage< 10% of the samples | ||

| Hydrostatic test | 20 95 95 95 | 1 22 165 1000 | 16.0 4.2 3.8 3.5 | 3 | No burst, no leakage | |

| Melt mass-flow rate MFR (230℃/2.16kg) | g/10min | 3 | Change rate≤30% of the raw materials | |||

| Thermal stability test under hydrostatic condition | 110 | 8760 | 1.9 | 1 | No burst, no leakage | |

| Size of the PPR Pipe SDR11/S5/PN10 | |||

| Nominal Outer Diameter | Diameter | Wall Thickness | Inner Diameter |

| 20 | 20 | 2.0 | 16.0 |

| 25 | 25 | 2.3 | 20.4 |

| 32 | 32 | 2.9 | 26.2 |

| 40 | 40 | 3.7 | 32.6 |

| 50 | 50 | 4.6 | 40.8 |

| 63 | 63 | 5.8 | 51.4 |

| 75 | 75 | 6.8 | 61.4 |

| 90 | 90 | 8.2 | 73.6 |

| 110 | 110 | 10 | 90.0 |

| 160 | 160 | 14.6 | 130.8 |

| Size of the PPR Pipe SDR9/S4/PN12.5 | |||

| Nominal Outer Diameter | Diameter | Wall Thickness | Inner Diameter |

| 20 | 20 | 2.3 | 15.4 |

| 25 | 25 | 2.8 | 19.4 |

| 32 | 32 | 3.6 | 24.8 |

| 40 | 40 | 4.5 | 31.0 |

| 50 | 50 | 5.6 | 38.8 |

| 63 | 63 | 7.1 | 48.8 |

| 75 | 75 | 8.4 | 58.2 |

| 90 | 90 | 10.1 | 69.8 |

| 110 | 110 | 12.3 | 85.4 |

| 160 | 160 | 17.9 | 124.2 |

| Size of the PPR Pipe SDR7.4/S3.2/PN16 | |||

| Nominal Outer Diameter | Diameter | Wall Thickness | Inner Diameter |

| 20 | 20 | 2.8 | 14.4 |

| 25 | 25 | 3.5 | 18.0 |

| 32 | 32 | 4.4 | 23.3 |

| 40 | 40 | 5.5 | 29.0 |

| 50 | 50 | 6.9 | 36.2 |

| 63 | 63 | 8.6 | 45.6 |

| 75 | 75 | 10.3 | 54.4 |

| 90 | 90 | 12.3 | 65.4 |

| 110 | 110 | 15.1 | 79.8 |

| Size of the PPR Pipe SDR6/S2.5/PN20 | |||

| Nominal Outer Diameter | Diameter | Wall Thickness | Inner Diameter |

| 20 | 20 | 3.4 | 13.2 |

| 25 | 25 | 4.2 | 16.6 |

| 32 | 32 | 5.4 | 21.2 |

| 40 | 40 | 6.7 | 26.6 |

| 50 | 50 | 8.3 | 33.4 |

| 63 | 63 | 10.5 | 42.0 |

| 75 | 75 | 12.5 | 50.0 |

| 90 | 90 | 15.0 | 60.0 |

| 110 | 110 | 18.3 | 73.4 |

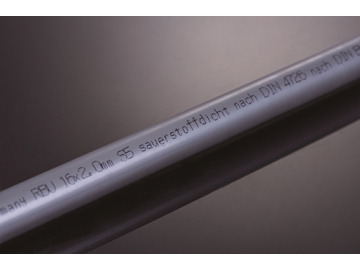

German Standard: DIN8077/8088

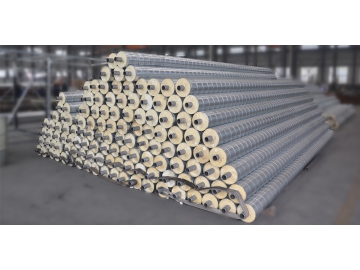

Supplied Form: 4m straight lengths

Color: White, green, blue, yellow, grey and other custom colors

Safety Coefficient =1.5

Raw Material: HYOSUNG R200P, BOROUGE R-130E

OEM: Available

Welcome to be our agent.

Attentions

1. The PPR pipes and fittings should be stored in airy warehouse or simple shed. They must avoid being stored in the open air or exposed to the sunshine directly. Additionally, they should be stored at least 1m away from a heat source.

2. The pipes need to be put on the ground neatly and avoids bending. They should be stacked layer by layer and the stacking height is not allowed to exceed 2m.

3. You should be cautious and gentle when you move the pipes and fittings and keep them away from greasy dirt, severe impact or sharp objects. Be sure not to throw, drop, roll or drag the pipes and fittings.

4. Do not use hard objects to rap the PPR pipes and fittings, especially when the ambient temperature is low.

5. The tubing must be cut along the direction perpendicular to its axial direction and the cut must be smooth.

6. The hot melting connection of the pipes should be done in strict accordance with the required depth. The maximum deviation angle between the pipe and fitting shall not exceed 50° during hot melting connection.

7. When bending the PPR pipes, the bending radius is not allowed to be shorter than 8 times of the diameter of the pipe. Never use open flame to heat the pipes for bending.

8. When connecting the PPR composite pipe to brass fittings, fiber or PTFE thread seal tape can be used for sealing but remember not to tighten them too tightly.

9. To connect two cross or overlapping pipes, you must use elbow fittings.

10. PP pipeline for water supply shall not be used for climbing.

11. After the directly buried pipes are enclosed. There should be markings on the ground or walls indicating the position and laying direction of the buried pipes. Never nail metal nails or other sharp objects onto the pipes.