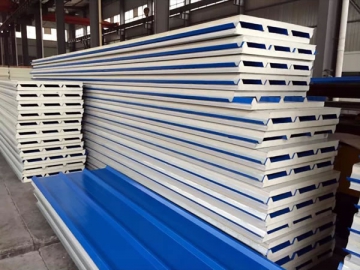

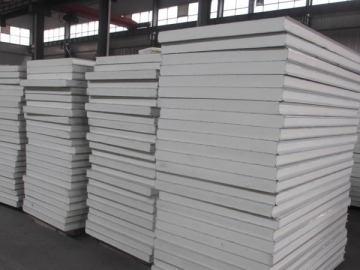

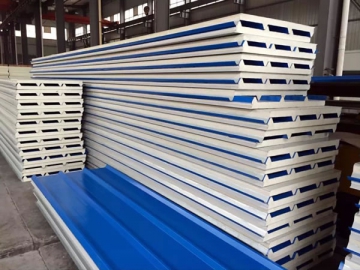

PU Sandwich Panel Line

The PU sandwich panel line is a composite material production line that integrates advanced mechanical, chemical, electrical, hydraulic, and pneumatic technologies.

Applications of PU Sandwich Panel Line

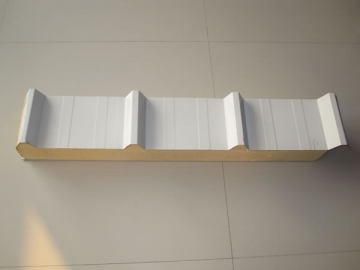

Featuring high efficiency and simple operation, this metal forming machine is regularly utilized for the manufacturing of PU sandwich panels which are often used as insulated wall and roof panels for steel structures, cold storages, and mobile buildings.

In order to suit varied customer demands, we can design and manufacture PU sandwich panel production lines in different specs, models and configurations.

Technical Data of PU Sandwich Panel Line| Sandwich Panel Spec. | ||

| Min. cutting length | 3 meters | |

| Max. stacking length | 15m | |

| Panel width | 1000mm (can be designed as per client's requirement) | |

| Panel thickness | Mini. thickness | 40mm (corrugated sandwich panel) |

| 50mm (wall panel) | ||

| Max. thickness | 150mm (excluding corrugated sandwich panel) | |

| Steel Sheet Spec. | ||

| Thickness | 0.4-0.7mm (color steel sheet) | |

| Width | 1250mm (can be designed as per client's requirement) | |

| Max. steel coil weight | 10 tons | |

| Inner dia. of steel coil | 508mm | |

| Whole Production Line Spec. | ||

| Production speed | About 3-7m/min (adjustable) | |

| Total length | about 105m | |

| Working height | 1200mm (height of panel coming out) | |

| Pressure for foaming | 150-200 bar | |

| Double belt conveyor | 23m | |

| Control mode | Mitsubishi PLC and converter | |

| Total power | About 100Kw (as per final designing) | |

| Power required | 380V/3phase/50Hz or as per customer's requirement. | |

| Air pressure | 0.7Mpa (for buyer to prepare) | |

-

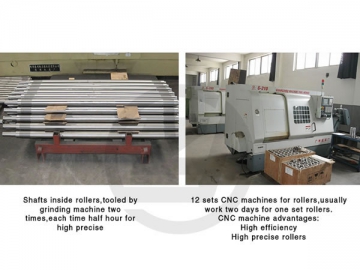

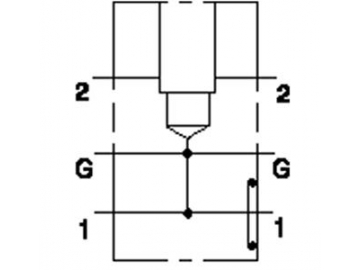

Roll forming machines forms panels up and down sheets. Machine’s lifetime can be more than 10 years.

-

23m double belts conveyor makes panels more even.

-

Fly cutting style cuts panels automatically according to set length.

-

Mitsubishi PLC controller with automatic mode and manual mode, realize continuous production.