Self-Cleaning Brush Screen Filter, ST

- Installation: vertical installation

- Flow rate (single filter): 15-1800 m³/h (larger flow can be obtained by connecting multiple units in parallel)

- Nominal pressure: 1.0 MPa, 1.6 MPa

- Operating pressure: 0.20-1.0 MPa

- Maximum operating temperature: 60 ℃

- Filtration degree: 200-3500 micron

- Control mode: differential pressure/timing/manual

- Cleaning time: 35-120 s

- Cleaning mechanism speed: 14-20 rpm

- Cleaning method: electric brush cleaning

- Cleaning pressure loss: 0.01-0.08 MPa

- Operating voltage: AC 380V, 50Hz, three-phase four-wire

- Control voltage: AC 220V, 50Hz

- LCD display interface, user-friendly design, easy operation

Technical Specifications | Model | Inlet/outlet connection (mm) | Max. flow rate (m³/h) | Filtration area (cm²) | Drain valve DN (mm) | D (mm) | Water consumption per cycle (L) | Motor power (kW) | Weight (kg) |

| ST-100 | DN100/10 | 80 | 3800 | DN50/10 | 325 | 130 | 0.55 | 230 |

| ST-125 | DN125/10 | 100 | 4500 | DN50/10 | 325 | 130 | 0.55 | 250 |

| ST-150 | DN150/10 | 150 | 4500 | DN50/10 | 325 | 130 | 0.55 | 260 |

| ST-200 | DN200/10 | 300 | 5100 | DN50/10 | 325 | 130 | 0.55 | 280 |

| ST-250 | DN250/10 | 400 | 9100 | DN50/10 | 400 | 180 | 0.75 | 420 |

| ST-300 | DN300/10 | 500 | 10000 | DN50/10 | 530 | 180 | 0.75 | 510 |

| ST-350 | DN350/10 | 800 | 14400 | DN50/10 | 620 | 200 | 0.75 | 650 |

| ST-400 | DN400/10 | 1000 | 17000 | DN80/10 | 720 | 250 | 0.75 | 760 |

| ST-500 | DN500/10 | 1800 | 30000 | DN80/10 | 920 | 250 | 0.75 | 950 |

The flow accuracy in the table is 400 μm . If in need of PN25 pressure rating, we can customize upon request. For other technical parameters, please consult Xuyang for details.

Installation Dimensions | Model | ST-100 | ST-125 | ST-150 | ST-200 | ST-250 | ST-300 | ST-350 | ST-400 | ST-500 |

| H | 500 | 540 | 550 | 630 | 630 | 750 | 750 | 750 | 900 |

| H1 | 990 | 1070 | 1090 | 1200 | 1200 | 1360 | 1390 | 1480 | 1525 |

| H2 | 1120 | 1280 | 1300 | 1420 | 1450 | 1650 | 1750 | 1810 | 2120 |

| L | 650 | 700 | 650 | 700 | 850 | 950 | 1050 | 1300 | 1650 |

| L1 | 283 | 283 | 283 | 283 | 345 | 415 | 475 | 515 | 650 |

Self-Cleaning Brush Screen Filter, STS

- Installation: vertical installation

- Flow rate (single filter): 15-1800m³/h (larger flow can be obtained by connecting multiple units in parallel)

- Nominal pressure: 1.0 MPa, 1.6 MPa

- Operating pressure: 0.20-1.0 MPa

- Maximum operating temperature: 60 ℃

- Filtration degree: 200-3500 micron

- Control mode: differential pressure/timing/manual

- Cleaning time: 35-120s

- Cleaning mechanism speed: 14-25 rpm

- Cleaning method: electric brush cleaning

- Cleaning pressure loss: 0.01-0.08 MPa

- Operating voltage: AC 380V, 50Hz, three-phase four-wire

- Control voltage: AC 220V, 50Hz

- LCD display interface, user-friendly design, easy operation

Technical Specifications | Model | Inlet/outlet connection (mm) | Max. flow rate (m³/h) | Filtration area (cm²) | Drain valve DN (mm) | D mm | Water consumption per cycle (L) | Motor power (kW) | Weight (kg) |

| STS-50 | DN50/10 | 25 | 2800 | DN25/10 | 325 | 130 | 0.55 | 170 |

| STS-80 | DN80/10 | 40 | 3400 | DN25/10 | 325 | 130 | 0.55 | 180 |

| STS-100 | DN100/10 | 80 | 4100 | DN40/10 | 325 | 150 | 0.55 | 210 |

The flow accuracy in the table is 400 μm. For other technical parameters, please consult Xuyang for details.

Self-Cleaning Brush Screen Filter, SY

- Installation: online installation

- Flow rate (single filter): 15-400 m³/h (larger flow can be obtained by connecting multiple units in parallel)

- Nominal pressure: 1.0 MPa, 1.6 MPa

- Operating pressure: 0.20-1.2 MPa

- Maximum operating temperature: 60 ℃

- Filtration degree: 20-3500 micron

- Control mode: differential pressure/timing/manual

- Cleaning time: 35-120s

- Cleaning mechanism speed: 14-20 rpm

- Cleaning method: electric brush cleaning

- Cleaning pressure loss: 0.01-0.08 MPa

- Operating voltage: AC 380V, 50Hz, three-phase four-wire

- Control voltage: AC 220V, 50Hz

- LCD display interface, user-friendly design, easy operation

Technical Specifications | Model | Inlet/outlet connection (mm) | Max. flow rate (m³/h) | Filtration area (cm²) | Drain valve DN (mm) | D mm | Water consumption per cycle (L) | Motor power (kW) | Weight (kg) |

| SY-50 | DN50/10 | 25 | 3300 | DN25/10 | 275 | 130 | 0.55 | 170 |

| SY-80 | DN80/10 | 40 | 3600 | DN25/10 | 275 | 130 | 0.55 | 180 |

| SY-100 | DN100/10 | 80 | 4000 | DN40/10 | 275 | 150 | 0.55 | 210 |

| SY-150 | DN150/10 | 150 | 4500 | DN50/10 | 275 | 130 | 0.55 | 240 |

| SY-200 | DN200/10 | 300 | 6000 | DN50/10 | 325 | 130 | 0.55 | 260 |

| SY-250 | DN250/10 | 400 | 7500 | DN50/10 | 400 | 180 | 0.55 | 420 |

The flow accuracy in the table is 400 μm. For other technical parameters, please consult Xuyang for details.

Installation Dimensions | Model | SY-50 | SY-80 | SY-100 | SY-150 | SY-200 | SY-250 |

| H | 720 | 750 | 820 | 850 | 980 | 1020 |

| L | 720 | 720 | 760 | 800 | 1050 | 1080 |

| L1 | 335 | 335 | 410 | 435 | 350 | 360 |

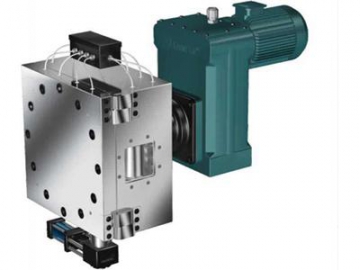

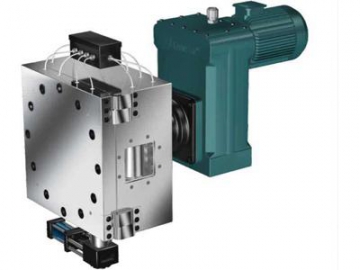

Self-Cleaning Brush Screen Filter, SM

- Installation: horizontal installation

- Flow rate (single filter): 150-400 m³/h (larger flow can be obtained by connecting multiple units in parallel)

- Nominal pressure: 1.0 MPa, 1.6 MPa

- Operating pressure: 0.20-1.2 MPa

- Maximum operating temperature: 60 ℃

- Filtration degree: 20-3500 micron

- Control mode: differential pressure/timing/manual

- Cleaning time: 35-120 s

- Cleaning mechanism speed: 14-20 rpm

- Cleaning method: electric brush cleaning

- Cleaning pressure loss: 0.01-0.08 MPa

- Operating voltage: AC 380V, 50Hz, three-phase four-wire

- Control voltage: AC 220V, 50Hz

- LCD display interface, user-friendly design, easy operation

Technical Specifications | Model | Inlet/outlet connection (mm) | Max. flow rate (m³/h) | Filtration area (cm²) | Drain valve DN (mm) | D mm | Water consumption per cycle (L) | Motor power (kW) | Weight (kg) |

| SM-150 | DN150/10 | 150 | 4500 | DN50/10 | 325 | 130 | 0.55 | 260 |

| SM-200 | DN200/10 | 300 | 5100 | DN50/10 | 325 | 130 | 0.55 | 280 |

| SM-250 | DN250/10 | 400 | 9100 | DN50/10 | 400 | 180 | 0.75 | 460 |

The flow accuracy in the table is 400 μm. For other technical parameters, please consult Xuyang for details.

Installation Dimensions | Model | SM-150 | SM-200 | SM-250 |

| B | 700 | 700 | 850 |

| C | 720 | 700 | 900 |

| C1 | 270 | 300 | 330 |

| L | 350 | 350 | 400 |

| L1 | 1000 | 1000 | 1200 |

| A | 295 | 350 | 410 |

Self-Cleaning Brush Screen Filter, SSY

- SSY manual self-cleaning filter

- Installation: online installation

- Flow rate (single filter): 15-80 m³/h (larger flow can be obtained by connecting multiple units in parallel)

- Nominal pressure: 1.0 MPa, 1.6 MPa

- Operating pressure: 0.20-1.0 MPa

- Maximum operating temperature: 60 ℃

- Filtration degree: 200-3500 micron

- Control mode: manual

- Cleaning time: 15-120 s

- Cleaning method: manual brush cleaning

- Cleaning pressure loss: 0.01-0.08 MPa

Technical Specifications | Model | Inlet/outlet connection (mm) | Max. flow rate (m³/h) | Filtration area (cm²) | Drain valve DN (mm) | D mm | Water consumption per cycle (L) | Weight (kg) |

| SSY-50 | DN50/10 | 25 | | DN25/10 | 275 | 60 | 50 |

| SSY-80 | DN80/10 | 40 | | DN25/10 | 275 | 60 | 60 |

| SSY-100 | DN100/10 | 80 | | DN25/10 | 275 | 80 | 120 |

The flow accuracy in the table is 400 μm. For other technical parameters, please consult Xuyang for details.

Self-Cleaning Brush Screen Filter, STN (for Sea Water)

- Installation: vertical installation

- Flow rate (single filter): 150-1800 m³/h (larger flow can be obtained by connecting multiple units in parallel)

- Nominal pressure: 1.0 MPa, 1.6 MPa

- Operating pressure: 0.20-1.0 MPa

- Maximum operating temperature: 60 ℃

- Filtration degree: 200-3500 micron

- Control mode: differential pressure/timing/manual

- Cleaning time: 15-120 s

- Cleaning mechanism speed: 14-25 rpm

- Cleaning method: electric brush cleaning

- Cleaning pressure loss: 0.01-0.08 MPa

- Operating voltage: AC 380V, 50Hz, three-phase four-wire

- Control voltage: AC 220V, 50Hz

- LCD display interface, user-friendly design, easy operation

Technical Specifications | Model | Inlet/outlet connection (mm) | Max. flow rate (m³/h) | Filtration area (cm²) | Drain valve DN (mm) | D mm | Water consumption per cycle (L) | Motor power (kW) | Weight (kg) |

| STN-150 | DN150/10 | 150 | 4500 | DN50/10 | 325 | 130 | 0.55 | 260 |

| STN-200 | DN200/10 | 300 | 5100 | DN50/10 | 325 | 130 | 0.55 | 280 |

| STN-250 | DN250/10 | 400 | 9100 | DN50/10 | 400 | 180 | 0.75 | 420 |

| STN-300 | DN300/10 | 500 | 10000 | DN50/10 | 530 | 180 | 0.75 | 510 |

| STN-350 | DN350/10 | 800 | 14400 | DN50/10 | 620 | 200 | 0.75 | 650 |

| STN-400 | DN400/10 | 1000 | 17000 | DN80/10 | 720 | 250 | 0.75 | 760 |

| STN-500 | DN500/10 | 1800 | 30000 | DN80/10 | 920 | 250 | 0.75 | 950 |

The flow accuracy in the table is 500 μm. For other technical parameters, please consult Xuyang for details.

Control System - Industrial single-chip PLC for an automatic control experience with a Chinese or English interface.

- A range of control options for the automated filter cleaning, including pressure differential and set timers. Manual and forced cleaning operations available.

- Adjust filtering and cleaning times right at the location.

- This filter offers a range of outputs for operation, cleaning, and fault signals, as well as a 485 communication interface.

Electric automatic self-cleaning brush screen filter - Filter shell material: carbon steel covered with epoxy resin powder, stainless steel, duplex steel and carbon steel with a plastic lining.

- Screen filter material: stainless steel, duplex steel

- Self-cleaning device: stainless steel, duplex steel, nylon

- Blowdown valve: cast iron

- Seal ring: nitrile rubber and silicone rubber.

- Control box: PVC