Automatic Self-Cleaning Suction Scanning Screen Filter, X Series

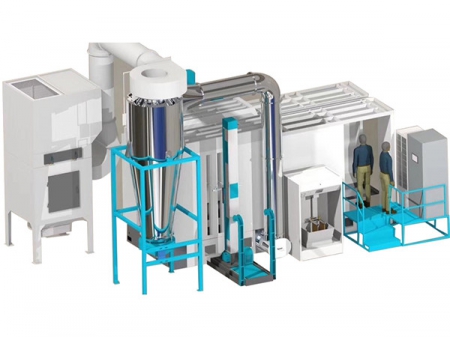

The self-cleaning suction scanning screen filter series comes in three variations-the XT vertical, XM horizontal, and XTD-providing a comprehensive filtration system for any application. Each filter utilizes powerful electric suction for cleaning and can be equipped with a filter screen, ranging from 20 to 500 micron, in different diameters from 2" to 24".

Self-Cleaning Suction Scanning Screen Filter, XT

Self-Cleaning Suction Scanning Screen Filter, XM

Self-Cleaning Suction Scanning Screen Filter, XTD

Self-Cleaning Suction Scanning Screen Filter, XMG

Water impurities are intercepted by the fine filter screen of the filter and accumulate on the inner surface of the screen, forming a filter cake that traps even the finer impurities. In this way, the dirty water is filtered and the self-cleaning suction scanning screen filter starts a cleaning cycle when the pressure difference between the inlet and outlet of the water reaches a predetermined value.

- The cleaning component is crafted from 304 stainless steel, featuring a suction scanner capable of both rotation and vertical movement, as well as multiple suction ports.

- The suction scanner boasts a 3" electric blowdown valve connected to its interior. This valve can be opened during cleaning, allowing a pressure difference between the internal water pressure and the outside atmosphere to create a vigorous suction force. Consequently, any contaminants are washed out of the scanner and expelled through the blowdown valve.

- The powerful reverse water flow created at the suction port is capable of effectively removing the difficult-to-get-rid-of contaminants stuck on the filter screen.

- This suction scanner is propelled by an electric bi-directional motor, which is synced with a screw rod mechanism that sorts out the spiral reciprocating motion, all while maintaining a specific rotational speed. This instrument is outfitted with a collection of suction ports that can effectively vacuum the entirety of the internal filter screen.

- The entire backwashing procedure typically requires 30-120 seconds while keeping the flow online.

Cooling water treatment:

A process that utilizes filtration to reduce sediment accumulation in heat exchangers, thus boosting the cooling power of cooling towers, air conditioning systems and DC systems. In addition, the water filtration keeps the make-up water system in top condition.Water source treatment:

A procedure to obtain clean surface water from rivers, lakes, seas, reservoirs and wells. This technique can remove unwanted particles including sand, bacteria, algae, and organic material.Industrial circulating water filtration:

Employed on equipment that requires specific water quality standards, such as coolers and rolling mills, as well as continuous casting machines, polishing equipment, pumps, electromagnetic valves and ion exchangers, sprayers and radiators. This form of filtration helps eradicate contaminants from the water, preventing blockages that could otherwise occur in pipes, hoses, and other components.Irrigation:

Highly suitable for water sources with high flow and impurities, and can be used for various purposes, such as agricultural irrigation, park sprinkling, golf courses, and sports fields.The paper industry:

efficient white water filtration in its operations.- The plastic industry: the filtration and circulation of cooling water to optimize injection processes.

- Membrane, resin and ultrafiltration pretreatment

- Seawater desalination systems and mariculture filtration systems with pretreatment filtration.

- Installation: vertical installation

- Flow rate (single filter): 15-1800 m³/h; larger flow can be obtained by connecting multiple units in parallel.

- Nominal pressure: 1.0 MPa, 1.6 MPa

- Operating pressure: 0.20-1.2 MPa

- Maximum operating temperature: 60 ℃

- Filtration degree: 50-800 micron

- Control mode: differential pressure/timing/manual

- Cleaning time: 25-120 s

- Cleaning mechanism speed: 14-20 rpm

- Cleaning method: suction scanning cleaning.

- Cleaning pressure loss: 0.01-0.08 MPa

- Operating voltage: AC 380V, 50Hz, three-phase four-wire

- Control voltage: AC 220V, 50Hz

- LCD display interface, user-friendly design, easy operation

| Model | | | | | | | |

| Inlet/outlet connection (mm) | 150 | 200 | 250 | 300 | 350 | 400 | 500 |

| Max. flow rate (m³/h) | 150 | 300 | 400 | 600 | 900 | 1200 | 1800 |

| Filtration area (cm²) | 6500 | 6500 | 11500 | 12500 | 13500 | 16500 | 16500 |

| Electric drain valve DN (mm) | 50 | 50 | 80 | 80 | 80 | 80 | 80 |

| Water consumption per cycle (L) | 150 | 150 | 400 | 400 | 400 | 450 | 450 |

| Motor power (kW) | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 |

| Approx. weight (kg) | 500 | 500 | 620 | 655 | 720 | 910 | 980 |

The flow accuracy in the table is 200 μm. For other technical parameters, please consult Xuyang for details.

| Model | | | | | | | |

| H | 580 | 600 | 720 | 720 | 700 | 800 | 800 |

| H1 | 1100 | 1120 | 1413 | 1413 | 1417 | 1525 | 1525 |

| H2 | 1720 | 1750 | 2080 | 2080 | 2110 | 16500 | 2200 |

| L | 880 | 900 | 1000 | 1000 | 1200 | 1500 | 1600 |

| L1 | 350 | 350 | 415 | 415 | 475 | 565 | 565 |

- Installation: horizontal installation

- Flow rate (single filter): 20-1200 m³/h (larger flow can be obtained by connecting multiple units in parallel)

- Nominal pressure: 1.0 MPa, 1.6 MPa

- Operating pressure: 0.20-1.2 MPa

- Maximum operating temperature: 60 ℃

- Filtration degree: 50-800 micron

- Control mode: differential pressure/timing/manual

- Cleaning time: 35-120 s

- Cleaning mechanism speed: 14-20 rpm

- Cleaning method: suction scanning cleaning.

- Cleaning pressure loss: 0.01-0.08 MPa

- Operating voltage: AC 380V, 50Hz, three-phase four-wire

- Control voltage: AC 220V, 50Hz

- LCD display interface, user-friendly design, easy operation

| Model | | | | | | | | |

| Inlet/outlet connection (mm) | 50 | 80 | 80 | 150 | 200 | 250 | 300 | 350 |

| Max. flow rate (m³/h) | 100 | 100 | 150 | 200 | 300 | 400 | 600 | 900 |

| Filtration area (cm²) | 1750 | 1750 | 3200 | 3200 | 6500 | 11500 | 12500 | 13500 |

| Electric drain valve DN (mm) | 50 | 50 | 50 | 50 | 50 | 80 | 80 | 80 |

| Water consumption per cycle (L) | 150 | 150 | 150 | 150 | 150 | 400 | 400 | 400 |

| Motor power (kW) | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | 0.55 | 0.75 |

| Approx. weight (kg) | 120 | 130 | 180 | 210 | 480 | 710 | 780 | 830 |

The flow accuracy in the table is 200 μm. For other technical parameters, please consult Xuyang for details.

| Model | | | | | | | | |

| A | 260 | 260 | 260 | 345 | 345 | 415 | 415 | 470 |

| A1 | 230 | 230 | 260 | 345 | 345 | 372 | 372 | 400 |

| B | 360 | 360 | 620 | 700 | 700 | 900 | 900 | 950 |

| C | 830 | 830 | 800 | 1050 | 1100 | 1120 | 1070 | 1150 |

| C1 | 300 | 300 | 250 | 350 | 300 | 385 | 345 | 510 |

| L | 500 | 500 | 800 | 900 | 900 | 1200 | 1200 | 1200 |

| L1 | 400 | 400 | 400 | 450 | 450 | 500 | 500 | 500 |

- Installation: vertical installation

- Flow rate (single filter): 1200-3500 m³/h (larger flow can be obtained by connecting multiple units in parallel)

- Nominal pressure: 1.0 MPa

- Operating pressure: 0.20-0.60MPa

- Maximum operating temperature: 60 ℃

- Filtration degree: 50-800 micron

- Control mode: differential pressure/timing/manual

- Cleaning time: 35-500 s

- Cleaning mechanism speed: 14-20 rpm

- Cleaning method: suction scanning cleaning.

- Cleaning pressure loss: 0.01-0.08 MPa

- Operating voltage: AC 380V, 50Hz, three-phase four-wire

- Control voltage: AC 220V, 50Hz

- LCD display interface, user-friendly design, easy operation

| Model | | | |

| Inlet/outlet connection (mm) | 500 | 600 | 700 |

| Max. flow rate (m³/h) | 2000 | 3000 | 4000 |

| Filtration area (cm²) | 13500X4 | 13500X4 | 13500X4 |

| Electric drain valve DN (mm) | 80-4 | 80-4 | 80-4 |

| Water consumption per cycle (L) | 400-4 | 400-4 | 400-4 |

| Motor power (kW) | 0.75-4 | 0.75-4 | 0.75-4 |

| Approx. weight (kg) | 1300 | 1400 | 1500 |

The flow accuracy in the table is 300 μm. For other technical parameters, please consult Xuyang for details.

- Installation: horizontal installation

- Flow rate (single filter): 20-1200 m³/h (larger flow can be obtained by connecting multiple units in parallel)

- Nominal pressure: 1.0 MPa

- Operating pressure: 0.20-0.60 MPa

- Maximum operating temperature: 60 ℃

- Filtration degree: 20-500 micron

- Control mode: differential pressure/timing/manual

- Cleaning time: 35-120 s

- Cleaning mechanism speed: 14-20 rpm

- Cleaning method: suction scanning with high pressure water flushing cleaning

- Cleaning pressure loss: 0.01-0.08 MPa

- Operating voltage: AC 380V, 50Hz, three-phase four-wire

- Control voltage: AC 220V, 50Hz

- LCD display interface, user-friendly design, easy operation

| Model | | | | | | |

| Inlet/outlet connection (mm) | 150 | 200 | 250 | 300 | 350 | 400 |

| Max. flow rate (m³/h) | 200 | 300 | 400 | 600 | 900 | 1200 |

| Filtration area (cm²) | 6500 | 6500 | 11500 | 13500 | 13500 | 16500 |

| Electric drain valve DN (mm) | 50 | 50 | 80 | 80 | 80 | 80 |

| Water consumption per cycle (L) | 150 | 150 | 400 | 400 | 400 | 450 |

| Motor power (kW) | 0.55 | 0.55 | 0.75 | 0.55 | 0.75 | 0.75 |

| Auxiliary flushing pump power (kW) | 2.2 | 2.2 | 2.2 | 2.2 | 3.0 | 3.0 |

| Approx. weight (kg) | 500 | 550 | 610 | 680 | 700 | 760 |

The flow accuracy in the table is 200 μm. For other technical parameters, please consult Xuyang for details.

- Industrial single-chip PLC for an automatic control experience with a Chinese or English interface.

- A range of control options for the automated filter cleaning, including pressure differential and set timers. Manual and forced cleaning operations are available.

- Adjust filtering and cleaning times right at the location.

- This filter offers a range of outputs for operation, cleaning, and fault signals, as well as a 485 communication interface.

- Filter shell material: carbon steel covered with epoxy resin powder, stainless steel, duplex steel

- Screen filter material: stainless steel, duplex steel

- Self-cleaning device: stainless steel, duplex steel

- Blowdown valve: cast iron

- Seal ring: nitrile rubber and silicone rubber.

- Control box: PVC