Skid-Mounted Drilling Rigs

Since petroleum drilling machine came into being, skid-mounted drilling rig has been the basic and most widely used type. Although it is not as easy to be moved as the mobile (self-propelled) drilling machine, skid-mounted drilling machine has flexible structure with steady derrick, powerful drilling capacity and strong adaptive capacity to environment. After AC variable frequency driving is applied into drilling equipment, skid-mounted drilling machine shows more obvious advantages compared with self-propelled drilling machine which has to be equipped with a diesel engine for vehicle running. As the improvement of technology, mounting, dismounting and transport of skid-mounted drilling machine is becoming more and more convenient and efficient.

- This machine adapts a hydraulic transmission box featuring small size, light weight, easy shift and stable working performance.

Our product is designed with an A-shaped derrick. There is wide operating space and open visual field around the wellhead. Thus our drilling machine is safe in use.

- The key components of this machine are driven by mechanical transmission. The whole machine is a highly cost effective product which is easy to operate and maintain.

- This series of skid-mounted drilling rigs include three models that are respectively ZJ40/2250J, ZJ40/2250LDB and ZJ40/2250L. They are suitable for being applied in drilling engineering to drill wells with the depth lower than 4000m. They can be used in different environments such as shallow sea areas ...

Including models of ZJ50/3150D and ZJ50/3150L, our ZJ50 series skid-mounted drilling rigs can be used to drill wells with the depth not exceeding 5000m. Based on the practical need of customers, they can work in shallow sea areas, beaches, deserts cold areas, etc.

A hydraulic disk brake is installed on the drawworks. The drawworks has the functions of automatic bit feeding with constant pressure, metical and electric collision protection, and emergency operation.

Composition

Our skid-mounted drilling rig is composed of several modules that are the derrick, substructure (including basic pedestal, drill floor, the backstage floor) and the pedestal for computer room.

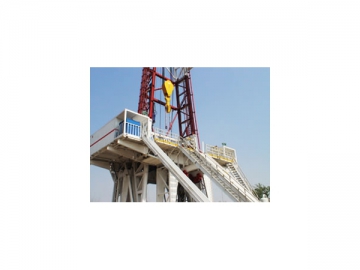

1. Derrick

Derrick, which is the most important part of a skid-mounted drilling machine, is mainly used to support lifting devices like the crown block, traveling block and the hook. The derrick can be used to place slurry circulation equipment such as the standpipes, swivel and the water hoses. It has the function of bearing the load generated in operations like tripping in or out the drilling bit, feeding in the casing pipe, and salvaging. Besides, it also provides height and space for tripping in or out as well as placing the drill stand.

2. Substructure

The substructure of a skid-mounted drilling rig can be classified into box-on-box type and self-lifting type. The substructure is mainly for placing the derrick, power units, driving system, drawworks, rotary table, drill rod, etc. It also provides space for the drilling operation platform and other wellhead equipment.

3. Driving System

With modular design, the driving system is quite suitable for skid-mounted drilling machine. This system has compact structure and is stable in performance to adapt to the drilling condition and the requirement of frequent movement.

Features

1. The K-shape derrick which is made of H-shape steel offers an open operating visual field and is easy to be transported. The derrick of our skid-mounted drilling rig complies with the PRC national standard of SY/T5609-1999 (Types and Basic Parameters of Petroleum Drilling Machines). Its design and manufacturing conform to specifications of API 4E, 4F (Specification for Drilling and Well Servicing Structures) and SY/T5025-1999.

2. The block-type substructure allows the drawworks and derrick to be mounted in a lower position. The drawworks provides power to lift the derrick up.

3. Our skid-mounted drilling rig is equipped with an integrated control cabin in which the driller can control almost all the operations.

4. Connected by universal shafts, the transmission system is easy to mount and dismount.

5. With a reasonable structure, this drilling machine is suitable for integral hoisting and is convenient to be transported in block by train or automobile.

6. We can offer a complete set of drilling machine producing the eight major systems. With high degree of mechanization, this skid-mounted drilling machine can be widely used in various fields and environments.