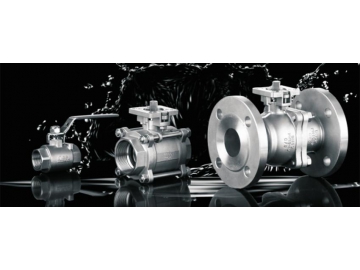

RBV010 Series Wafer Resilient Seated Butterfly Valve

The design of our RBV010 series wafer resilient seated butterfly valve meets strict requirements of industrial application, so this quarter-turn valve is able to work properly and steadily in different working conditions. It innovatively adopts a blow-out proof design by mounting a locating ring between processed stem groove and upper seal, so as to maintain the position of stem in case there is internal fault caused by an accident.

- RBV010A

- RBV010B

- RBV010C

Application

Water treatment, sea water desalination, irrigation, partition cooling system, electric power, sulfur removal, petroleum refining, oil field, ship, iron and steel, aluminum manufacturing, mining, chemical engineering, ultrapure water, pharmacy, food processing, beverage, brewing, sugaring, papermaking, HAVC, etc.

Working Environment and Materials

1. Applicable Temperature

The valve seat is available in various materials, which enables the butterfly valve to be applied at different ambient temperature.

| Material | Working Temperature |

| EPDM | -20℉ (-29℃ )~250℉ (121℃ ) |

| Buna-N | 0℉ (-18℃ )~212℉ (100℃ ) |

| Viton | 0℉ (-18℃ )~400℉ (204℃ ) |

| Polyurethane | -20 ℉ (-29℃ )~176℉ (80℃ ) |

| PTFE-Lined EPDM (Standard) | -20℉ (-29℃ )~250℉ (121℃ ) |

| PTFE-Lined EPDM (High-Temperature) | -20℉ (-29℃ )~302℉ (150℃ ) |

| Virgin PTFE & Conductive PTFE | 0℉ (-18℃ )~392℉ (200℃ ) |

| UHMWPE | 0℉ (-18℃ )~185℉ (85℃ ) |

2. Materials

There are various kinds of valve disc material and valve seat material options, so as to satisfy different demands for media and working condition. Our experienced sales engineer can offer professional suggestions and service in accordance with your needs.

| Part Name | Material |

| Body | Cast Iron |

| Ductile Iron | |

| Body Coating | Epoxy Coating |

| Disc | ASTM 304/316 Stainless Steel |

| Super Duplex Stainless Steel | |

| Aluminum Bronze | |

| Disc Surfacing | Electroplating |

| Nylon Coating | |

| Halar Coating | |

| Coated with NBR | |

| Coated with PTFE | |

| Stem | ASTM 304/316 Stainless Steel |

| ASTM 416/420 Stainless Steel | |

| Super Duplex Stainless Steel | |

| Monel Metal | |

| Seat | NBR |

| Food Grade EPDM/EPDM | |

| Viton | |

| Silicon Rubber | |

| PTFE |

Design Features

1. High Compatibility

1) Upper Flange

The flange achieves ISO5211 standard. It can be equipped with the handle, worm gear, pneumatic actuator or the electric actuator. The actuator can be easily installed on site without any bracket, which reduces error and lowers overall height.

2) Side Flange

It is based on compatible connection design. The end connection reaches DINPN10/16 and ASME Class150 standards.

2. Two-way Sealing

On the basis of midline soft sealing design, the butterfly valve comes with two-way sealing, zero leakage and easy opertion. Its installation is not restricted by the flow direction of media. Owing to leakproofness, it is perfect for isolating or regulating gas flow.

3. Full Rubber-lined Seat

Since our seat can completely separate the body from media within the pipeline, the body just makes use of standard anti-corrosion material instead of super one, considerably bringing down costs.

4. Blow-Out Proof Dry Stem

Due to special structure and axial sealing design, the stem can be entirely isolated from media. Therefore, different from the super corrosion-proof stem of some butterfly valves, our valve stem is always kept dry and only applies standard stem material.

5. Small Operation Torque

The interference fit between a valve disc and a seat has been accurately calculated, and the sealing surface of disc has undergone polishing treatment, which dramatically reduces operation torque and facilitates operation. Its actuator is reliable and efficient.

6. Easy Installation and Replacement

1) With lighter weight and smaller size, the butterfly valve is easy to install.

2) To take it apart, the operator just need to extract the stem from the disc, which ensures easy replacement.

7. Full Bore Design

1) The design maximizes discharge coefficient, and minimizes loss of flow.

2) Body

It is based on the wafer design. All its drill holes are able to achieve DINPN10, DIN PN16 and ASME Class150 standard.

3) Exterior Coating

a) Our standard body is coated with static epoxy, so as to guarantee corrosion resistance and abrasion resistance. In addition, optional surface treatment methods are hammer paint spraying, nylon coating, polyphenylene sulfide flame spraying, Halar coating, and anti-condensation coating.

b) To achieve perfect spraying effect, the body of butterfly valve will be galvanized before epoxy spraying. The galvanization treatment can be replaced by abrasive blasting or pickling in line with your demands, which effectively saves costs. Other coating is available, if required.

- Hammer Paint

- Polyphenylene Sulfide

- Anti-condensation Coating

- Epoxy Coating

- Galvanization

4) Disc

As a high-strength casting, the disc of butterfly valve is proud of small operation torque and long working life. Its edge has received spherical machining and manual polishing. Its streamlined design reduces flow resistance, increases Cv value, improves pressure recovery capability and enhances performance of this flow control device. The outer diameter clearance supports connection to various kinds of standard pipes.

5) Seat

a) EPDM is the abbreviation of ethylene propylene diene monomer. In general industrial filed, EPT, Nordel, ECD and EPR all belong to EPDM. As standard material of our seat, EPDM features wide application and attractive price. Our food grade seat has passed WRAS certification, and is suitable for food processing and standard industrial fields.

b) The skeleton-style rubber seat of RBV010-H butterfly valve can be manufactured from phenolic resin or aluminum in line with your needs.

c) The RBV010C1 and RBV010C2 adopt groove-style rubber seat. There is an integrated waterline on the end surface, leaving out the flange gasket. The seat performs well in firm installation, quick replacement and small torque.

6) Stem

a) You can choose single-stem without pin or double-stem without pin design. The connection between disc and stem has been machined finely, eliminating the possibility of hysteresis and strengthening all the connections.

b) Since both the stem and the disc are capable of preventing dust or bacteria, the butterfly valve is widely used in industries with a high demanding on sanitation. To resist to corrosion and abrasion, the stem and disc are completely wrapped in EPDM or BUNA-N.

c) As to double-stem without pin design, a flat or square stem end is innovatively connected to a disc without screws or pins, so as to drive the disc directly.

7) Shaft Sleeve

The shaft sleeve of butterfly valve is made of anti-corrosive phenolic resin or PTFE to absorb lateral thrust. It can also be manufactured from brass.

8) Primary Seal and Secondary Seal

The seals totally separate fluid media from body and stem. The primary one refers to the prepressing contact between the shoulder of disc and the internal surface of seat. The secondary one directs at the interference fit between the stem and the seat hole. The self-adjusting triple O-shape seal design guarantees two-way sealing and prevents foreign substances from entering into the cavity of stem.