Details Show

1. Damping Absorbtion

We use 3 circle and 4 circle top quality steel tubes to absorb the impacts caused by the kelly bar's pressure working.

2. Key trail

We use 6 keys drive trails at international standards to manufacture our kelly bar. Our key steel all undergoes heat treatment and straightening, and then welding on the tube.

3. Inner teeth section

This section is very important for the kelly bar. The quality of the inner teeth section can affect the entire kelly bar's service life. The inner three key plate uses a 300mm wide, quality steel plate, imported from Germany. After heat treatment, the plate is cut to the right size for application needs, then welded into the tube.

4. Square Head Joint Structure Patent

This structure is used to increase the wearability of square head. Throughout our 10 years of manufacturing production, we have not had any complaints from customers about broken kelly bar square heads., leading to use applying for this patents, which was awarded in 2014.

5. Interlocking Kelly Bar Pressure Block Patent

Pressure block are also key components to the interlocking kelly bar. Factories both at home and aboard all use a single riveting hole pressure block. This situation does not reduce the kelly bar's abrasion resistance. However, we use a double riveting hole block to greatly increase our kelly bar's service life. We were awarded this patent in 2014.

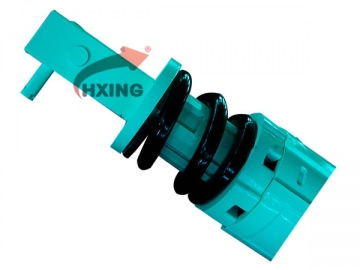

6. Kelly Bar Up and Down Protective Moving Device

All of our kelly bars are equipped with an up and down protective moving device. This device can effectively prevent kelly bars from free falling when lifting and pulling. This patent was awarded in 2013.

7. Kelly Bar Protecting Ring Patent

Protecting rings are used for anti-impact among every elements kelly bar. There are many factories using 40mm and 50mm width protecting rings, but only we use an 80mm wide protecting ring. We applied for this patent in year 2012, and it was awarded to us on the 27th of March 2013.