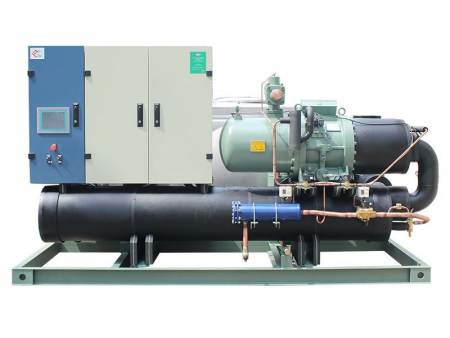

Water-Cooled Screw Chiller

Chilled water system for commercial applications

This high-efficiency twin screw compressor water-cooled screw type chiller is perfect for all cooling needs in large and medium-sized industrial and commercial places. With a capacity range of 70 kw - 5000 kw, use of R22, R134a and other refrigerants are available options. Additionally, the flexible modular design system enables a choice of 380V-50Hz-3N and other power supply systems that deliver chilled water outlet temperatures ranging from 5-20 degrees.

-

Energy efficient

The major components and patented intellectual property are all manufactured by ourselves, ensuring optimal system capacity. The total COP of this unit reaches 6.0. Moreover, the water-cooled chiller may feature our distinctively patented heat recovery device, capable of recovering more than 30% of cooling potential or the full amount with air conditioning. Further, the hot water's maximum temperature can reach 70°C. Heat recovery does not consume energy, but offers a five-percent boost in total unit efficiency.

-

Intelligent control

The controller of the chiller uses an advanced HMI control that boosts the defensive capacities of the comprehensive setup. The Siemens PLC controller, providing Modbus RTU, TCP, and S7 communication, can be chosen optionally.

-

Safe and secure

This system, tailored specifically for high precision water outlet, has been designed with various safety protocols to guarantee the unit's safe operation. Every unit has been rigorously tested against the safety detection system before being shipped out, guaranteeing its performance is up to national standards.

-

Easy installation and maintenance

The chiller unit have already been equipped with a refrigerant and compressor oil during the production, making it simple for the customer to connect the inlet and outlet pipes and power supply to get it up and running. Thanks to a clear and easy to understand control interface, any potential faults can quickly be identified, allowing swift repair. Additionally, each component in the unit has been carefully designed for maximum accessibility, making maintenance a breeze.

Water-Cooled Screw Chiller

Refrigerant: R134a

Power supply: 380V-3N-50Hz

| Model | Nominal cooling capacity | Power input kW | Capacity control % | Refrigerant charge kg | Condenser | Evaporator | Noise level dB(A) | Shipping weight kg | Operating weight kg | |||||||

| Pipe diameter (inlet/outlet) in | Water flow m3/h | Design water pressure MPa | Water pressure drop kPa | Pipe diameter (inlet/outlet) in | Water flow m3/h | Design water pressure MPa | Water pressure drop kPa | |||||||||

| kW | USRT | |||||||||||||||

| | 68 | 19 | 14 | 0 66 100 | 17 | 2-1/2″ | 14 | 1 | 41 | 2″ | 12 | 1 | 65 | 73 | 1020 | 1130 |

| | 95 | 27 | 18 | 24 | 2-1/2″ | 19 | 1 | 47 | 2″ | 16 | 1 | 68 | 74 | 1060 | 1170 | |

| | 126 | 36 | 23 | 31 | 2-1/2″ | 26 | 1 | 45 | 2″ | 22 | 1 | 65 | 75 | 1250 | 1410 | |

| | 175 | 50 | 33 | 0 50 75 100 | 41 | 3″ | 36 | 1 | 53 | 3″ | 30 | 1 | 68 | 75 | 1400 | 1580 |

| 180 | 51 | 34 | 45 | 3″ | 37 | 1 | 52 | 3″ | 31 | 1 | 70 | 76 | 1580 | 1730 | ||

| | 298 | 85 | 53 | 68 | 3" | 60 | 1 | 50 | 4″ | 51 | 1 | 65 | 76 | 2700 | 2930 | |

| | 340 | 97 | 60 | 75 | 4" | 69 | 1 | 52 | 4" | 58 | 1 | 68 | 77 | 2880 | 3150 | |

| | 400 | 114 | 70 | 81 | 4" | 81 | 1 | 52 | 4" | 69 | 1 | 65 | 77 | 3600 | 3960 | |

| | 449 | 128 | 78 | 98 | 5″ | 91 | 1 | 54 | 4" | 77 | 1 | 68 | 77 | 4100 | 4370 | |

| | 516 | 147 | 90 | 119 | 5″ | 104 | 1 | 56 | 5″ | 89 | 1 | 70 | 78 | 4410 | 4910 | |

| | 572 | 163 | 98 | 136 | 5" | 115 | 1 | 50 | 5" | 98 | 1 | 70 | 78 | 4730 | 5180 | |

| | 615 | 175 | 106 | 149 | 5″ | 124 | 1 | 55 | 5″ | 106 | 1 | 70 | 79 | 5360 | 5590 | |

| | 719 | 204 | 121 | 162 | 5" | 144 | 1 | 58 | 5″ | 124 | 1 | 75 | 79 | 5670 | 6190 | |

| | 823 | 234 | 140 | 183 | 5″ | 166 | 1 | 60 | 5″ | 142 | 1 | 78 | 80 | 6170 | 7070 | |

| | 1047 | 298 | 174 | 225 | 6″ | 210 | 1 | 75 | 6″ | 180 | 1 | 82 | 81 | 7250 | 8060 | |

| | 1171 | 333 | 192 | 0 25 37.5 50 62.5 75 87.5 100 | 306 | 6“ | 234 | 1 | 76 | 6" | 201 | 1 | 72 | 82 | 8550 | 9180 |

| | 731 | 208 | 130 | 204 | 5" | 148 | 1 | 52 | 5″ | 126 | 1 | 64 | 82 | 4370 | 4950 | |

| | 800 | 227 | 140 | 213 | 5" | 162 | 1 | 52 | 5″ | 138 | 1 | 64 | 82 | 5200 | 5470 | |

| | 898 | 255 | 156 | 238 | 6″ | 181 | 1 | 53 | 6″ | 154 | 1 | 65 | 83 | 5450 | 5740 | |

| | 1032 | 293 | 180 | 272 | 6" | 208 | 1 | 55 | 6″ | 177 | 1 | 68 | 83 | 5630 | 6180 | |

| | 1230 | 350 | 212 | 340 | 8″ | 248 | 1 | 64 | 8″ | 212 | 1 | 80 | 84 | 9450 | 10400 | |

| | 1438 | 409 | 242 | 383 | 8″ | 289 | 1 | 64 | 8″ | 247 | 1 | 82 | 84 | 9610 | 11600 | |

| | 1646 | 468 | 280 | 476 | 8" | 331 | 1 | 65 | 8″ | 283 | 1 | 83 | 85 | 12190 | 13300 | |

| | 2094 | 595 | 348 | 621 | 10″ | 420 | 1 | 80 | 8″ | 360 | 1 | 95 | 86 | 15890 | 17910 | |

| | 2342 | 666 | 384 | 714 | 10″ | 469 | 1 | 81 | 10″ | 403 | 1 | 96 | 87 | 16720 | 18960 | |

| | 3513 | 999 | 576 | 1071 | 16″ | 703 | 1 | 85 | 16″ | 604 | 1 | 96 | 88 | 20000 | 22000 | |

Heat recovery

The chiller's condensing heat, typically released into the atmosphere via a cooling tower, can now be effectively harnessed. With the heat recovery technology, heat absorbed during cooling can be transferred to the building, providing hot water where needed. During the cooling season, the heat recovery unit can provide free hot water above 50°C, utilizing up to 30-100% of the cooling capacity for heat recovery.