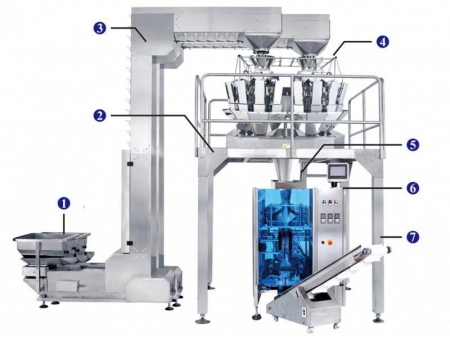

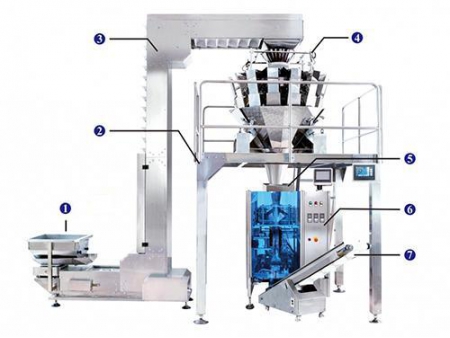

Vertical Form Fill Seal Machine with Linear Weigher, L420DL-D4T

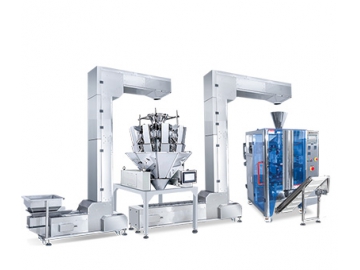

- The VFFS machine with linear weigher consists of a Z type elevator feeder, linear weigher, supporting platform, packaging machine, and a finished product conveyor.

- Bag format: pillow bag. A carry handle or gusset is optional.

- Applications: granular and powdery items like sugar, salt, seeds, sesames, peanuts, grains, beans, etc.

The electronic linear weigher can weigh multiple materials at the same time, enabling mixed products packaging. An electrodeless vibrating feeder is adopted to evenly dispense products, increase the load capacity and automatically adjust vibration amplitude.

A modular and integrated control system allows for direct paraments adjustment during operation based on the actual production situation to simplify operations.

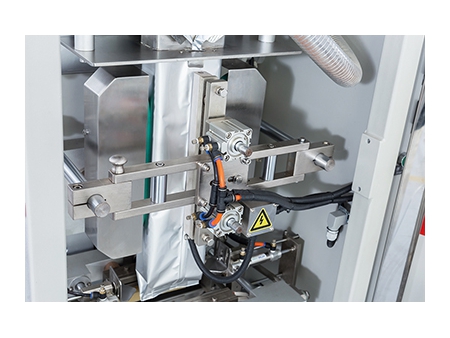

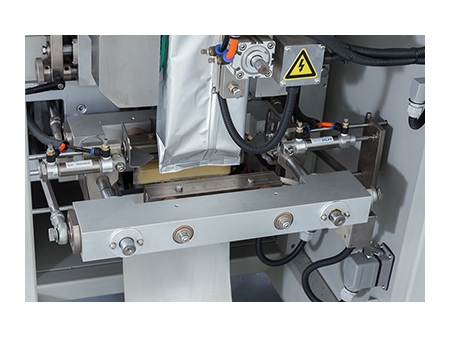

The packaging machine is controlled by a Panasonic servo motor and a single/double film drawing system is adopted to ensure the film transporting stability and bag forming smoothness. SMC/Airtac air cylinder helps to improve bag sealing property and reduce the failure rate.

External film unwind apparatus simplifies film changeovers. The standard code printer uses intermittent ribbon coding to ensure the color fastness of the printed date.

PLC control, Panoramic driver and Wienview touch screen feature simple operation and are sensitive to touche. The operation system supports a variety of languages, including English, Russian, French, Spanish, Arabic, Korean, Persian, etc.

The combination of elevator and weigher performs material level control and vibration disk feeding to enable auto feeding start and stop and auto feeding speed control according to actual conditions.

Stainless steel or carbon steel are both options for the elevator material. Food-grade plastic is used for the hopper material and features a capacity of 2L or 4L depending on your requirements.

Driven by micro motors, the finished bags are conveyed to the platform. The conveying capacity is up to 60-80 bags per minute with high smoothness and low noise.

The conveyor belt can be designed separately to fit your specific requirements. For example, PVC belt, stainless steel chain conveyor or PVC chain conveyor are optional based on the characteristics of your product materials.

| Model | SK-L380-D4T | SK-L420-D4T | SK-L520-D4T |

| Filling capacity | 30-500g | 100-1000g | 100-2000g |

| Bag width range | 50-180mm | 80-200mm | 100-250mm |

| Bag length range | 80-240mm | 80-300mm | 80-350mm |

| Speed | 5-85 bags/min | 5-80bags/min | 5-70bags/min |

| Material type | various film laminates | various film laminates | various film laminates |

| Machine Dimensions | L4500 * W2800 * H3700mm | L4500 * W2800 * H3700mm | L4500 * W2800 * H3700mm |

| Model | SK-L620-D2T | SK-L720-D2T | SK-L820-D2T |

| Filling capacity | 500-3000g | 500-5000g | 800-10000g |

| Bag width range | 150-300mm | 180-350mm | 200-400mm |

| Bag length range | 100-400mm | 100-500mm | 200-600mm |

| Speed | 5-55bags/min | 5-55bags/min | 5-50bags/min |

| Material type | various film laminates | various film laminates | various film laminates |

| Machine Dimensions | L4500 * W2800 * H3700mm | L4500 * W3000 * H4200mm | L4500 * W3000 * H4200mm |

If you are interested in our vertical form fill seal machine with linear weigher L420DL-D4T, you are welcome to contact us for more details.