Steel Belt Reduction Furnace

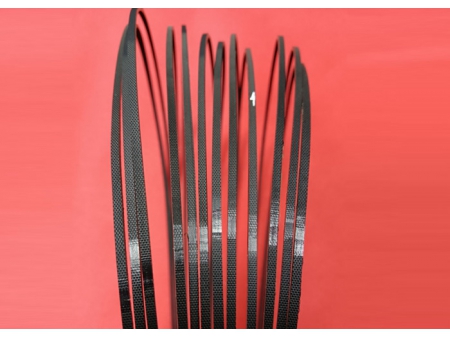

The steel belt reduction furnace is engineered for large volume reduction of metal powder including iron powder, copper powder, cobalt powder, molybdenum powder and tungsten powder, etc. This metal powder reduction furnace is also applicable for sintering of metal salts such as cobalt oxalate and APT, etc.

Advantage

1. Tremendous output

Metal powders are directly deployed uniformly on steel belt to make the best use of furnace room. Heat treatment is effectively acting on materials on the basis of fast adjustment on temperature and conveyor speed.

2. Low energy consumption

All fiber needlefelt carpet comes with modular structure, thus offering excellent thermal insulation, low energy storage and minimal heat loss.

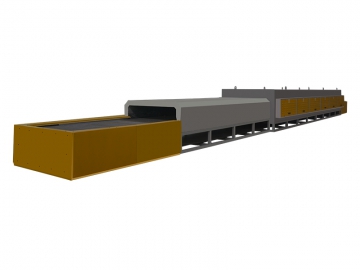

3. Durable furnace tube

Our steel belt reduction furnace is fitted with pre-pressing system for furnace tube. Moreover, we place silicon carbide board under furnace tube. The board has great rigidity, low coefficient of friction and considerable resistance to high temperature. As a result, metal tube receives balanced heating for smooth thermal expansion, and service life is 1.3 times more than similar products.

4. Exceptional automation

This tungsten powder reduction equipment has fully automatic control on temperature and production process. Comprehensive alarm system and interlocking protection ensure everything to be favorable in a holistic approach.

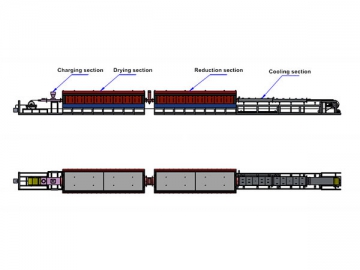

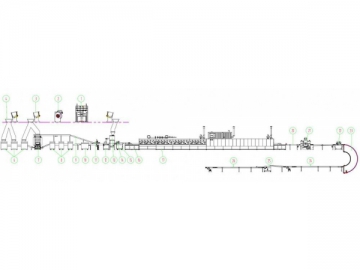

Structure

1. The entire steel belt reduction furnace comprises feeding unit, reduction unit, slow cooling unit, cooling unit, output unit and electronic control unit, etc.

2. The feeding unit in this powder processing equipment includes feeding platform and inlet muffle. There are hoppers on platform which can move with steel belt from left to right, thus maintaining uniformed feeding.

3. Reduction unit of this cobalt powder reduction furnace adopts ultra power effective structure. Modular all fiber needlefelt carpet is ceiling suspended on furnace top plate to prolong service life and reduced maintenance. Moreover, key parameters exceed national standards, such as power consumption of induction furnace, temperature rise and heating uniformity, etc.

4. Muffle in this steel belt reduction furnace is made up of heat resistant stainless steel and is welded by folded and corrugated steel. Specially enforced structure is designed in accordance with thermal and mechanical principles. SiC board is placed beneath for uniformed thermal expansion. Pre-pressing device is responsible for prolonged service life.

5. Inlet and outlet openings are enabled to be well hermitic by roller seal, gas seal or fiber seal, thus offering minimal gas consumption.

6. Conveyor system and multi-grade tension device are employed. Speed of steel belt is steplessly adjusted via variable-frequency drive, and is denoted by number.

7. This steel belt reduction furnace is equipped with intelligent temperature controller from Shimaden. This device employs self-adjustment and standard PID controller, whereby preventing temperature overshoot. Digital display readily realizes functions of selection, setting and configuration.

Main heating unit involves the combination of SCR series 3 phase thyristor power controller. In stead of traditional electrical on-off controlling mode, this controller utilizes continuous control not via on-off mode, but on the basis of temperature to automatically adjust heating power.

High accuracy and no noise generation can be achieved in temperature control for high power. In addition, there is no influence to internal power system.

Technical data| Model | ||||||

| Rated temperature (℃) | 950 | |||||

| Number of heating zone | 5 | 5 | 6 | 7 | 8 | 10 |

| Powder thickness (mm) | 19-39 Normally, iron powder thickness is 32mm. | |||||

| Steel belt speed (mm/min.) | 50-300 | |||||

| Production rate (kg/h) | 140 | 220 | 380 | 500 | 700 | 1000 |

| Rated power (kW) | 120 | 180 | 250 | 320 | 420 | 680 |

| Rated voltage (V) | 380 | |||||

| Hearth material | Heat resistant stainless steel SUS321, SUS310 | |||||

| Steel belt material | SUS321, SUS316L or SUS310s/&1.2mm | |||||

| Heating mode | Electric or gas heating | |||||

| Furnace structure | All cellucotton | |||||

| Temperature control | Shimaden temperature controller | |||||

Note

Non-standard steel belt reduction furnace is available in accordance with your requirements.

- Amorphous Alloy Powder Equipment

- Chemical Vapor Deposition Furnace

- Mesh Belt Atmosphere Brazing Furnace

Related Names

Metal Powder Reduction Machine | Powder Metallurgy Equipment