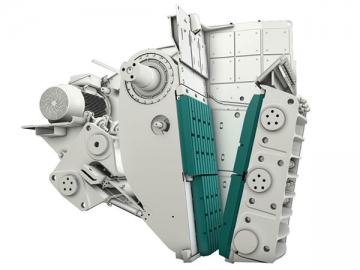

NH, NS Series Hydraulic Cone Crusher

The NH, NS series hydraulic cone crusher is specially developed by Mackorn to meet the needs of quarry owners or managers. It is designed in combination with the proved crushing theory and the professional knowledge of Swedish consultants. With required high performance and reliability, this high-speed cone crusher machine would achieve what your market wishes.

Our hydraulic cone crusher is smaller and lighter than similar products in the market, but it can offer a high level of crushing. Equipped with topnotch and durable spare parts with original packaging, this product can meet the stringent requirements for quarrying and crushing.

Main Design Features and Technical Advantages

The NS series product is a kind of advanced, high-yield, and high-speed secondary crushing equipment.

The NH series product is a type of high-yield, high-speed, and state-of-the-art tertiary crushing plant.

1. Dynamic Adjustment Settings

The fine crushing equipment is able to regulate the discharge opening settings by hydraulic pressure under load.

2. Versatility of Eccentricity and Crushing Chamber

The same type of hydraulic cone crusher can be chosen with different chambers and eccentricity so as to achieve required product specifications.

3. Easy Maintenance

Main components of the product can be disassembled from above for convenient maintenance. Also, a hydraulic oil station adopts human-oriented design concept, capacious inner space, and proper height for easy maintenance.

4. Durable and Safe Ball Bearing Design

Unique multi-faceted stress points extend replacement time of the accessory, while simultaneously reducing the phenomenon that copper bushes or other important spare parts are often damaged by excessive loss of a traditional bush with single-face stress points.

5. Optimized Cooling System Design

The optimized cooling system can well maintain the operating temperature, which enables the hydraulic cone crusher to work within the best temperature range.

6. Reinforced Design of Upper Frame Body

The reinforced design of upper frame body prolongs the service life of the crushing machine and also guarantees smooth operation for a long time.

Technical Parameters

| Standard Production Capacity (T/H) under Closed Side Setting CSS (mm) | ||||||||||||||||||||||

| NS Series Hydraulic Cone Crusher | Model | Motor Power | Chamber Model | Maximum Feed Size | 19 | 22 | 25 | 29 | 32 | 35 | 38 | 41 | 44 | 48 | 51 | 54 | 60 | 64 | 70 | 76 | 83 | |

| kW | mm | |||||||||||||||||||||

| 90 | EC | 240 | 85 | 92-115 | 101-158 | 107-168 | 114-143 | 121 | ||||||||||||||

| C | 200 | 70 | 76-95 | 82-128 | 90-112 | 96 | ||||||||||||||||

| 160 | EC | 360 | 126 | 138-173 | 147-230 | 156-293 | 165-310 | 174-327 | 183-344 | 196-306 | 205-256 | 214 | ||||||||||

| C | 300 | 108 | 116-145 | 127-199 | 135-254 | 144-270 | 152-285 | 161-301 | 169-264 | 180 | ||||||||||||

| MC | 235 | 91 | 98-123 | 106-166 | 116-218 | 124-232 | 131-246 | 139-246 | 147-275 | 154-241 | 165 | |||||||||||

| 250 | EC | 450 | 267 | 282-353 | 298-446 | 313-563 | 334-601 | 349-524 | 365-456 | |||||||||||||

| C | 400 | 225 | 239-299 | 254-381 | 269-484 | 284-511 | 298-448 | 318-398 | 333 | |||||||||||||

| MC | 300 | 195 | 214-267 | 228-342 | 242-435 | 256-461 | 270-486 | 284-426 | 303-378 | 317 | ||||||||||||

| 315 | EC | 560 | 349 | 368-460 | 392-588 | 410-718 | 428-856 | 465-929 | 489-978 | 525-1050 | 562-983 | 604 | ||||||||||

| C | 500 | 318 | 336-420 | 353-618 | 376-753 | 394-788 | 411-823 | 446-892 | 469-822 | 504-631 | ||||||||||||

| NH Series Hydraulic Cone Crusher | Standard Production Capacity (T/H) under Closed Side Setting CSS (mm) | |||||||||||||||||||||

| Model | Motor Power | Chamber Model | Maximum Feed Size | 4 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | 57 | 64 | 70 | |||

| kW | mm | |||||||||||||||||||||

| 90 | EC | 135 | 46 | 50-85 | 54-92 | 58-99 | 62-105 | 66-112 | 76-128 | |||||||||||||

| C | 90 | 43-53 | 46-89 | 50-96 | 54-103 | 57-110 | 61-118 | 70 | ||||||||||||||

| M | 65 | 36-44 | 38-74 | 41-80 | 45-76 | 48-59 | ||||||||||||||||

| MF | 50 | 36 | 38-67 | 32-57 | 35-48 | 38 | ||||||||||||||||

| F | 38 | 27-34 | 29-50 | 31-54 | 32-57 | 35-48 | 38 | |||||||||||||||

| EF | 29 | 30-40 (80% fineness of less than 4.5-5.5mm) | ||||||||||||||||||||

| 160 | EC | 185 | 69-108 | 75-150 | 80-161 | 86-171 | 91-182 | 104-208 | 115-208 | |||||||||||||

| C | 145 | 66-131 | 71-142 | 76-152 | 81-162 | 86-173 | 98-197 | 109-150 | ||||||||||||||

| MC | 115 | 57 | 62-140 | 67-151 | 72-162 | 77-173 | 82-184 | 93-145 | ||||||||||||||

| M | 90 | 64-84 | 69-131 | 75-142 | 80-152 | 86-162 | 91-154 | 104 | ||||||||||||||

| MF | 75 | 61 | 65-106 | 70-115 | 76-124 | 81-126 | 87-114 | 92 | ||||||||||||||

| F | 50 | 48-78 | 51-83 | 54-88 | 59-96 | 63-103 | 68-105 | 72-95 | 77 | |||||||||||||

| EF | 35 | 70-90 (80% fineness of less than 5-5.6mm) | ||||||||||||||||||||

| 250 | EC | 215 | 114-200 | 122-276 | 131-294 | 139-313 | 159-357 | 175-395 | 192-384 | |||||||||||||

| C | 175 | 101 | 109-218 | 117-292 | 125-312 | 133-332 | 151-378 | 167-335 | 183-229 | |||||||||||||

| MC | 140 | 97-122 | 105-262 | 113-282 | 120-301 | 128-320 | 146-328 | 161-242 | ||||||||||||||

| M | 110 | 117-187 | 126-278 | 136-298 | 145-318 | 154-339 | 176-281 | 194 | ||||||||||||||

| MF | 85 | 114 | 124-227 | 134-245 | 144-263 | 153-281 | 163-299 | 186-248 | ||||||||||||||

| F | 70 | 90-135 | 96-176 | 104-191 | 112-206 | 120-221 | 129-236 | 137-251 | 156-208 | |||||||||||||

| EF | 38 | 100-125 (80% fineness of less than 6-7.5mm) | ||||||||||||||||||||

| 315 | EC | 275 | 177 | 190-338 | 203-436 | 216-464 | 246-547 | 272-605 | 298-662 | 328-511 | ||||||||||||

| CX | 245 | 174-194 | 187-374 | 200-488 | 212-519 | 242-592 | 268-654 | 293-521 | 323-359 | |||||||||||||

| C | 215 | 171-190 | 184-367 | 196-480 | 209-510 | 238-582 | 263-643 | 288-512 | 317-353 | |||||||||||||

| MC | 175 | 162-253 | 174-426 | 186-455 | 198-484 | 226-552 | 249-499 | 273-364 | ||||||||||||||

| M | 135 | 197-295 | 211-440 | 226-470 | 240-500 | 274-502 | 302-403 | |||||||||||||||

| MF | 115 | 192 | 207-369 | 222-396 | 237-423 | 252-450 | 287-451 | 318-363 | ||||||||||||||

| F | 85 | 195-304 | 210-328 | 225-352 | 241-376 | 256-400 | 292-401 | 323 | ||||||||||||||

| EF | 65 | 211-293 | 227-316 | 244-298 | 261-290 | |||||||||||||||||

| 500 | EC | 300 | 448-588 | 477-849 | 544-968 | 601-1070 | 658-1172 | 725-1291 | 782-1393 | 849-1512 | 906-1331 | |||||||||||

| C | 240 | 406 | 433-636 | 461-893 | 525-1018 | 581-1125 | 636-1232 | 700-1357 | 756-1464 | 820-1461 | 876-1286 | |||||||||||

| MC | 195 | 380-440 | 406-723 | 432-837 | 492-954 | 544-1055 | 596-1155 | 675-1272 | 708-1373 | 769-1307 | 821-1206 | |||||||||||

| M | 155 | 400-563 | 428-786 | 455-836 | 519-953 | 573-1054 | 628-1154 | 692-1271 | 746-1372 | 810-1248 | 865-1098 | |||||||||||

| MF | 100 | 379-424 | 407-716 | 434-765 | 462-814 | 527-928 | 582-942 | 638-789 | 702 | |||||||||||||

| F | 90 | 357-395 | 385-656 | 414-704 | 442-752 | 470-800 | 535-912 | 592-857 | 649-718 | |||||||||||||

| EF | 80 | 280-405 | 304-517 | 328-558 | 352-598 | 376-639 | 400-680 | 455-775 | 503-728 | 551-669 | ||||||||||||

Remarks: Production Capacity, T/H

1. The data presented is general indicators of the crushing machine production performance. Data listed in the table is for the performance of our mining equipment during the open circuit production of dry materials with bulk density of 1.6T/M3. In addition, the maximum feed size assumed is the maximum feed size allowed by this crushing equipment without any fine material smaller than a closed side setting.

2. The crushing capacity of the hydraulic cone crusher may be affected by different factors such as the selected eccentricity, crushing ratio, crushing function index, feed size composition, circulating load, and the mud content in feed, etc. For detailed applications, please feel free to contact us.

3. The NS series hydraulic cone crusher has three optional standard crushing chambers: MC=medium coarse, C=coarse, EC=extra coarse.

4. The NH series hydraulic cone crusher has multiple optional crushing chambers: EEF=extremely fine, EF=extra fine, EFX=extra fine approximation, F=fine, MF=medium fine, M=medium, MC=medium coarse, C=coarse, CX=coarse approximation, EC=extra coarse.