Application

Are you looking to boost production efficiency and enhance the quality of your laminated films? Look no further! Our SUPLOCK solventless lamination machine is designed to do just that, it features duplex workstation and can achieve non-stop material changeover. It's a game-changer for various industries, including food packaging, pharmaceuticals, personal care products, laminated printing labels, vehicle interior protection film, and photovoltaic component protective films used in solar panel manufacturing.

Design Concept

After extensive visits to thousands of printing companies, we identified three common challenges when using solventless lamination:

- Moisture-induced Stretching: Nylon film tends to absorb moisture during material changes, leading to unwanted stretching and compromising lamination quality.

- Adhesive Overflow: Single-workstation solventless laminating machines often experience adhesive overflow during frequent stops and accelerations, particularly at low speeds.

- Unstable Product Quality: Frequent speed changes during material changes can negatively impact the stability of product quality.

Introducing Solventless Laminating Solutions

The underlying factor for these challenges? The need for machine stops and material changes, resulting in speed variations.

In response to customer demands, our technical research and development team explored various solutions. The result? A duplex solventless laminating machine that allows fast job changeover and non-stop operation, addressing all three challenges:

- Moisture Management: Continuous operation means nylon remains shielded from extended exposure to air, preventing moisture absorption and stretching.

- Adhesive Control: Constant-speed material changes eliminate adhesive overflow issues, even at low speeds.

- Stable Quality: Consistent-speed material changes enhance the stability of laminated product quality.

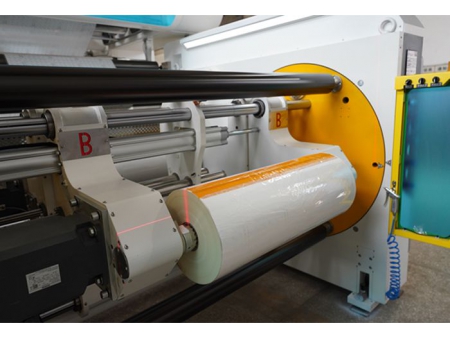

With the joint efforts of our technical research and development team, Siemens Digital Industries Group's technical support team, and Chongqing Weigen Industrial Design Co., Ltd., we proudly present the remarkable S2-1300A dual-workstation solventless laminator!

Experience higher work efficiency and redefine your perception of "duplex workstations." The S2-1300A solventless laminator is your solution for easy operation, improved quality, and cost savings!