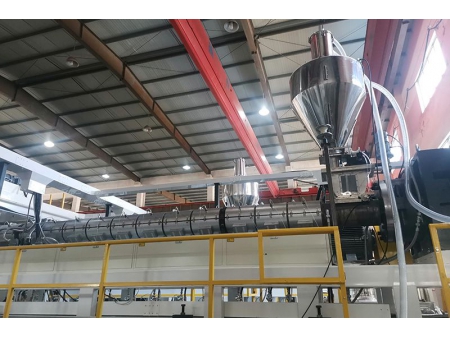

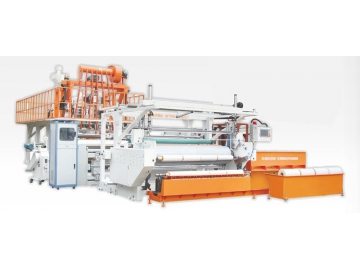

CPE Film Line

Extrusion line for producing cast polyethylene film (CPE film)

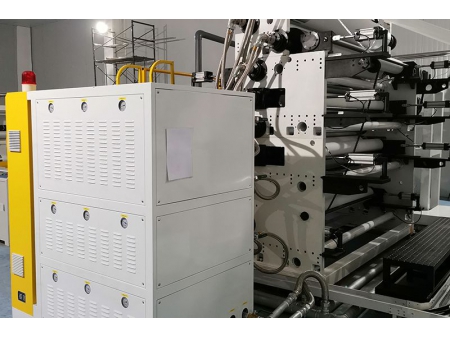

Our CPE film line incorporates advanced PLC technology, enabling film forming, corona treatment, edge cutting, and automatic duplex turret winder. The whole film extrusion line can be automatically controlled thanks to the functions of real-time parameter setting, display, diagnosis, and monitoring. In this way, PLC stabilizes the whole manufacturing process, improves efficiency and reduces human interferences.

Utilizing state-of-the-art plastic film extrusion and computer control techniques, the system achieves seamless automation for changeover, high-speed winding, meter preset, rapid film cutting. The operators can do settings and monitoring on the interface, as well as gather real-time data.

- Maximum Screw Extrusion Output: ≥1400kg/h

- Maximum Winding Speed: 200m/min (designed mechanical speed)

- Maximum Die Width: 3,800mm

- Maximum Film Width: 3,500mm

- Film Thickness: 30-100μm

- Maximum Winding Diameter: 1,000mm

- Applicable Material: Cast-grade polyethylene

- Power: Customized according to customer needs

- Production Volume: Customized according to film thickness

- Equipment Dimensions: Customized according to products needed by the customer

- Total Installed Power: Customized according to products needed by the customer

- The specially designed forming system ensures stable formation of flexible, highly transparent films with excellent uniformity in thickness and a wide range of heat tolerance.

- Centralized control of material handling, conveying, weighing, mixing and feeding

- Fully automatic system of film roll unloading, handling, and storage

- Extruder

Die

Die Cast system

Cast system Thickness gauge

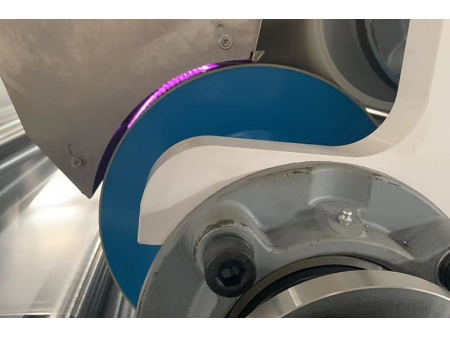

Thickness gauge Corona treatment

Corona treatment Edge cutting

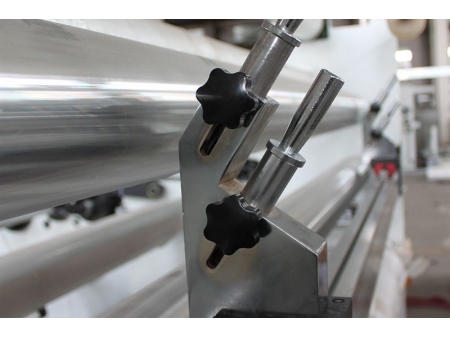

Edge cutting Winder

Winder Edge trim recycling

Edge trim recycling Film roll

Film roll Film storage

Film storage

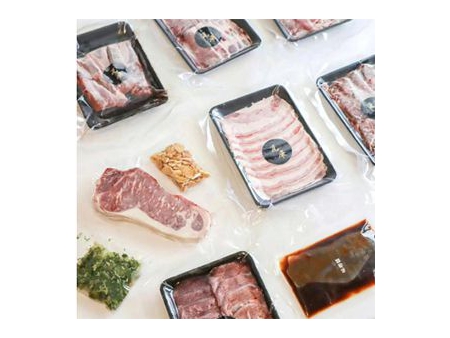

CPE film offers excellent transparency, puncture resistance, friction performance, composite properties, heat adhesion, and resistance to contamination during heat sealing.

Our CPE film line is primarily used for deep processing like color printing and plastic film laminating. The resulting CPE films are widely used in packaging for food, daily cosmetics, industrial products, and more.