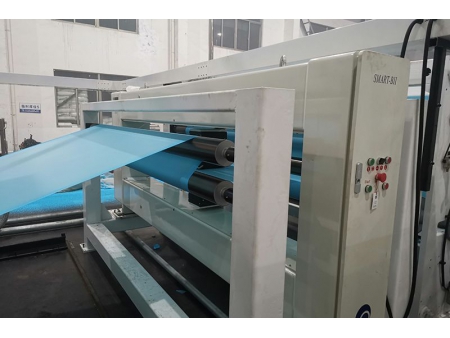

PE Embossed Film Line

Extrusion line for producing embossed film of baby diapers and sanitary napkins

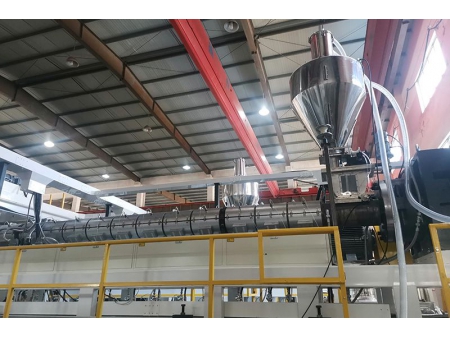

Our PE embossed film line is equipped with the screw that is highly compatible with raw materials, ensuring stable extrusion and high-precision output. It operates at a fast production speed with stable peeling. Additionally, our film production line allows for inline slitting and ensures smooth winding.

- Maximum Film Width: 3,200mm

- Film Thickness: 15-50gsm, 80-150gsm

- Maximum Production Speed: 220m/min

- Production Volume: 1,000kg/h

- Equipment Dimensions: 22m * 10m * 5m

- Total Installed Power: 550kW-800kW

- Often operated in single-extruder, but also available in dual-extruder or triple-extruder mode

- Equipped with automatic die and defect detection

- Equipped with gear pump which ensures high-precision output

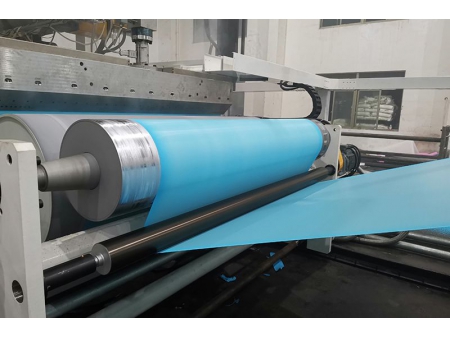

- Good peel-ability of embossing rollers and rubber roller

- High production speed of maximum 220m/min

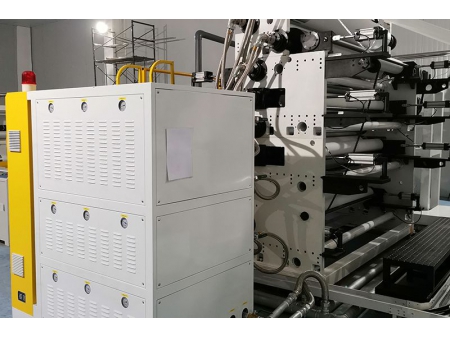

- Extruder

Die

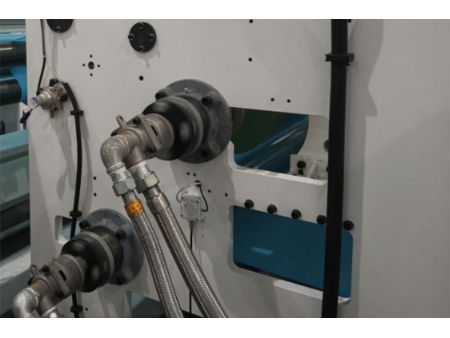

Die Cast system

Cast system Thickness gauge

Thickness gauge Corona treatment

Corona treatment Inline slitting

Inline slitting Winding

Winding

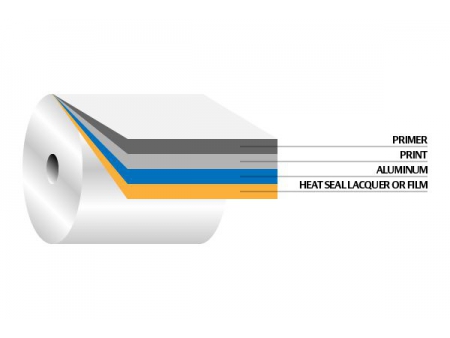

PE embossed film has frosted and diamond patterns on the surface, and can be widely used for medical protective and sanitary materials.

PE embossed film is primarily used in the hygiene industry for products like disposable personal care items, female sanitary pads, liners, baby diapers, adult incontinence products, medical protective items, surgical gowns, caps, shoe covers, and industrial protective gear.

Winding defects

Improper adjustment of film thickness

Tight film

Excessive tension during winding

Varying thickness of the film without changing settings or dies

Poor material dispersion

Inconsistent patterns on either side

Different pressure on each side of the rubber roller, check the roller medium height and the uniformity of hardness.

Poor manufacturing speed and peel-ability

Inadequate cooling of rubber roller before operation