EVA/POE Solar Film Extrusion Line

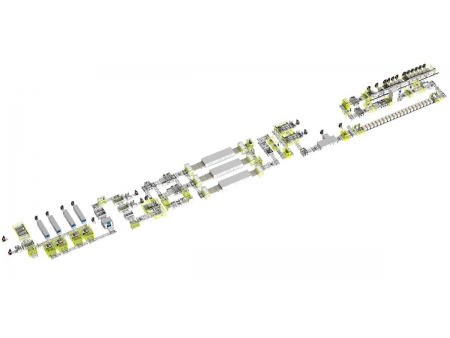

Solar panel film production line for manufacturing photovoltaic encapsulating film

At Sanxin, we take pride in offering a highly flexible solar film extrusion line that can be tailored to meet your specific requirements. Our goal is to provide you with specific solutions that address any challenges you may encounter, ensuring seamless alignment with your production and process needs.

The highlights include the followings:

- Production Speed Our solar panel film production line is engineered to operate at a speed of 20 meters per minute. Please note that the actual speed may vary depending on the type of raw materials used and other influencing factors.

- Automation Level Embrace cutting-edge technology with our cast film production line, featuring automatic changeover, film cutting, and roll loading. We have also integrated an interface for an AGV (Automated Guided Vehicle) to facilitate smooth and efficient material handling and production flow.

- Energy Efficiency Stay environmentally conscious with our solar panel film production line, designed to be more energy-efficient. We have fine-tuned the water circulation system, allowing for the use of low-temperature water when process requirements permit, significantly reducing energy consumption related to cooling equipment.

- Maximum Film Width: 1400mm*2 (customizable)

- Film Thickness: 0.1mm-0.8mm

- Maximum Production Speed: 20m/min

- Production Volume: 800-1100kg/h

- Equipment Dimensions: 26m*9m*5.3m

- Total Installed Power: 900kW

- Automatic winding and unloading reduces labor cost.

- Tuned water-circulation system lowers power consumption.

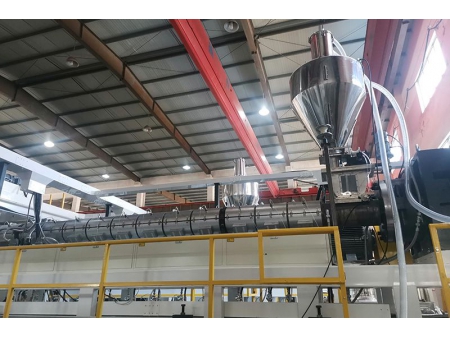

- Designed with a high quality extruder screw, which ensures good plasticization and high output.

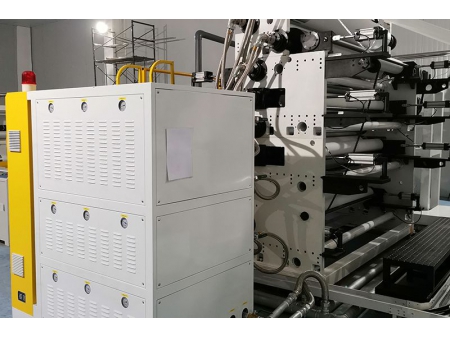

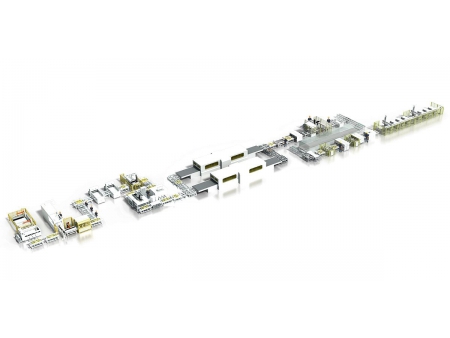

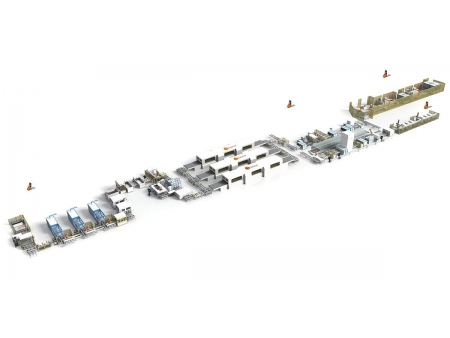

Extruder

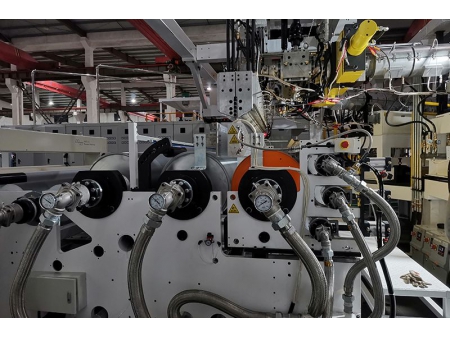

Extruder Die

Die Thickness gauge

Thickness gauge Embossing system

Embossing system Setting system

Setting system Inline slitting

Inline slitting Winder

Winder Film roll

Film roll Unloading & bagging

Unloading & bagging Water cooling station

Water cooling station

EVA (Ethylene Vinyl Acetate) is a thermosetting adhesive film used for bonding photovoltaic back sheets. Due to its outstanding adhesive strength, durability, and optical characteristics, EVA film has found widespread applications in solar panels and various optical products.

Solar cell encapsulation

Solar glass or photovoltaic back sheet encapsulation

How to address excessive static charge and obvious static marks on the film?

Please check if the equipment cable is properly grounded. If well grounded, then add static elimination before film winding, so as to ensure minimum static electricity.

What should I do if the film remains sticking even the rubber roller temperature is low.

Please inspect if there is blockage in the internal flow channel of roller. Flushing is required if there are significant temperature deviations in certain areas.

In addition, please check if there is excessive buildup of substances on the roller surface; if true, the roller should be re-grinded. We recommend the roller be sent back to the factory for re-surface grinding every two months.

How to deal with wrinkles and uneven edges on the films?

Please check if the roller is paralleled with the film, and if tension is appropriate.