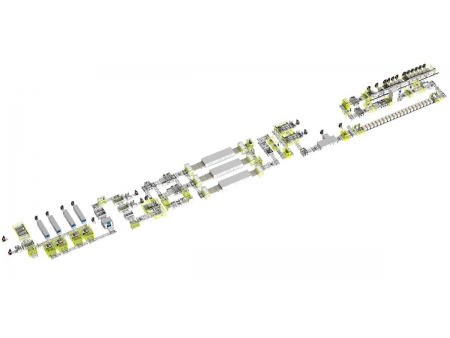

100MW Solar Panel Production Line

Request a Quote

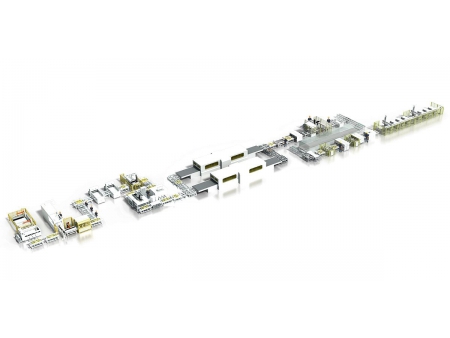

Turnkey solution for PV modules manufacturing

- 100 MW/year (22h, 330days)

- 25 modules/h

- 20-30 workers

- Application: 5BB-12BB; M6-M12

- Working noise: ≤70dBA.

- Stringer Machines

- Robot String Layup

- EVA/TPT Cutting & Layup

- EL & VI Tester

- Laminators

- Auto Framing Machine

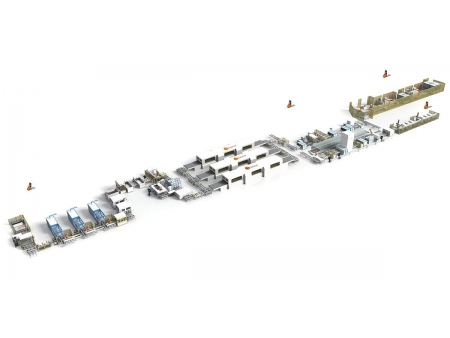

A 100MW solar module line is an automatic production line made up of quality individual equipment, like glass loading equipment, stringer machine, layup machine and laminators, to reduce manual cost to the maximum. The production line is also equipped with a MES system for production data monitoring to benefit the stable and reliable production.

The 100MW line can produce various types of solar panels, single and dual-glass, 5BB-12BB and monocrystalline and polycrystalline silicon. Each panel weighs up to 50kg and has a size up to 2,500mm*1,400mm. The biggest solar cell is M12 (210mm). And the cycle time is within 20 seconds.

PV Manufacturing Equipment List

- An automatic glass loading machine works to supply glass rapidly by automatically load, position and transport glass.

- An EVA cutting & layup machine can directly mix tailings with new materials through hot melting.

- A stringer machine uses the robotic system to position, grab and place solar cells, and applies infrared welding and automatic cutting to different cell strings.

- An automatic layup machine uses a robot to grab cell strings and adopts the contactless CCD positioning system for positioning precision.

- An EVA/TPT cutting & layup machine is used to cut and layup second EVA film and TPT backsheet with high precision cutting and layup technologies.

- An EL & VI tester can detect panel defects manually or with AI. Two inspection modes of EL and VI is available. The defects it can detect include cracks, broken grids, black spots, etc.

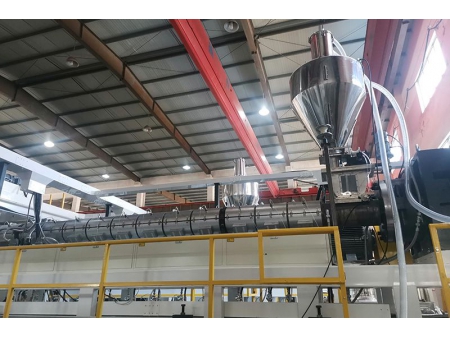

- An automatic laminator is a quality solar panel lamination machine and can be customized according to customer needs.

- An automatic edge trimming machine is used for automatic removal of burrs and exceed materials from PV module edges after lamination. The latest version also has an additional function of finer trimming.

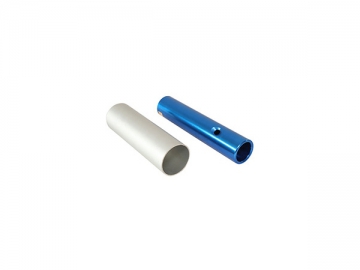

- An automatic framing machine is used for automatic silicon dispensing and assembling of solar panel frames. It features short cycle time and high precision to meet various panel framing needs.

- An auto J-box potting machine is composed of conveying, positioning and potting systems and used for automatic glue potting of PV junction boxes.

- A sun simulator provides a standard testing environment to know about the solar panel working conditions and conduct power and current tests on solar panels.

- An HiPot tester is an efficient and reliable machine used to test dielectric withstand and electrical insulation of PV modules.

- A vertical sorting machine is an automatic module sorter for sorting and sequencing of PV modules. It is capable of various sorting methods like long-side and short-side flat sorting and vertical sorting.

Three types of solar panel lines are available

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos