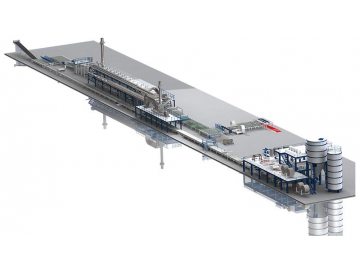

Dryer and Heat Exchanger Unit of Plasterboard Production Line

Dryer and heat exchanger unit consists of dispenser, dryer and discharger.

Processes of dryer and heat exchanger units strongly influence water containment of plasterboard, and finally decide whether a plasterboard is qualified. Therefore importance of dryer and heat exchanger unit is out of question.

LVJOE is well experienced, offering drying and heat exchanging devices of great qualities.

Two types: single belt and double belt. Double belt type is usually applied in dryer with over 10-layer roller path.

If a closing-up short roller is set on the dispenser, closing-up roller path is unnecessary.

(6-12 levels, according to production output)

Dryer is an essential part of the production line, a qualified dryer will effectively help ensure product’s quality, promote yield rate, decrease energy consumption and save cost.

LVJOE dryer is able to change direction of hot air flow by adjusting, which grants the ability to heat every plasterboard evenly, thus ensures drying quality of every board, and decrease energy consumption.

1. Types sorted by heat conduction method:direct heating type, indirect heating type, hot air heating type;

| Equipment Style | Direct heating type | Indirect heating type(million sqm/year) | Hot air heating type(million sqm/year) |

| Features | The hot air in the burner will go into the air circulation,the heat exchanging rate is high;Usually this type would take natural gas and diesel as fuel,is comparatively clean.The cost of fuel of this type is higher,but the heat exchanging rate is 10% to 20% higher than other types.The operation and maintenance for that,it is also environmental friendly. | The burner would heat the medium of the heat exchanger in the dryer.This medium inside the exchanger would heat further the air in the dryer,eventually dries the board.This medium could be steam or hot oil,for the latter got higher specific heat,is applied more widely. | The fuel in the hot air boiler would heat the clean air by the heat exchanger,then the hot air blow comes into being.Then the hot air would go to different zones of the dryer to dry the board.This type is adopted by the domestic new and big capacity production line. |

2. Sorted by hot air circulation method: vertical airflow dryer, horizontal airflow dryer, horizontal-vertical airflow dryer;

Vertical Airflow Dryer:Typical dryer type used in this industry. LVJOE’s vertical airflow dryer is designed with maintenance door and exterior bearing, which is convenient to inspect and maintenance. An adjustable panel is deployed to control hot airflow conveniently, thus to ensure quality of the product.

Horizontal Airflow Dryer:Horizontal airflow dryer applies modular design, able for increasing output by adding drying section extension according to need of output. Horizontal airflow dryer features short cross-flow path, so that multiple air inlet zones can be set, which grants the ability to flexibly control temperature and airflow direction. Therefore a better drying quality is achieved.

Horizontal-Vertical Airflow Dryer:Integrates advantages of vertical and horizontal airflow dryer, features high evaporation efficient, can flexibly modified according to output.

Drier`s Layer and capacity| Equipment Style | Direct heating type | Indirect heating type(million sqm/year) | Hot air heating type(million sqm/year) |

| Features | The hot air in the burner will go into the air circulation,the heat exchanging rate is high;Usually this type would take natural gas and diesel as fuel,is comparatively clean.The cost of fuel of this type is higher,but the heat exchanging rate is 10% to 20% higher than other types.The operation and maintenance for that,it is also environmental friendly. | The burner would heat the medium of the heat exchanger in the dryer.This medium inside the exchanger would heat further the air in the dryer,eventually dries the board.This medium could be steam or hot oil,for the latter got higher specific heat,is applied more widely. | The fuel in the hot air boiler would heat the clean air by the heat exchanger,then the hot air blow comes into being.Then the hot air would go to different zones of the dryer to dry the board.This type is adopted by the domestic new and big capacity production line. |

①Board inlet distributer applies absolute encoder for position metering, features stable running and precise locating performance;

②Automatic adjustment on inlet board slot, to reduce over burning;

③Temperature and humidity are automatically measured and adjusted, which ensures drying quality and decreases energy consumption;

④Optional energy consumption management system, visualized energy consumption management;

⑤Real-time displayed plasterboard position on master computer, which makes it convenient for on/off and temperature controlling, and helps decreasing wasting;

⑥Optimized placement control.