Electro-Hydraulic Press Brake

As a reliable sheet metal fabrication company, our WF67k electro-hydraulic CNC press brake is with high safety. Of rich available configurations and a much wider processing range, this sheet metal press brake enjoys highly precise and reliable performance as well as long service life.

Of a welded steel structure, this electro-hydraulic CNC press brake enjoys high mechanical precision and excellent properties, quite safe and convenient to operate. To be more specific, all the power facilities are mounted within the machine tool and controlled by the control board and pedal switches outside. In order to avoid overload and short circuit, the brake is also equipped with air switch.

Components of Electro-Hydraulic CNC Press Brake

1. Hydraulic Valves Block

2. Stroke

3. Gear Pump

4. Flange Type Connecting Seat

5. Master Motor

This structure of this bending machine comprises of the main motor, flanged connection seat, gear pump, hydraulic valves and sliding block. The gear pump is driven by the main motor and the clearance error between them would be solved by the flanged connection seat. Meanwhile, the pump and hydraulic valves are connected by the block transition instead of pipes. Both detailed designs significantly promote the mechanical life of this gear pump.

This back gauge is patent product developed by our company. The ball screws of this sheet metal brake are directly driven by the X-axis turbine and guided by the linear guide rails at both sides. This special design effectively avoids the precision error caused by the sprocket-wheel and chain design.

The electrical components of this bending machine tool are provided by Schneider(France). Schematic diagram and operation introduction on the inner side of the cabinet door could significantly help you operate the brake.

1. Quick Clamp

This is the deflection compensation device for the upper die of the quick-acting clamp.

Features of Electro-Hydraulic CNC Press Brake

1. Compared with its traditional counterparts, this electro-hydraulic CNC sheet metal bending brake enjoys much better properties. Comprising of quality gratings, the closed loop control system this brake adopts could control it in a highly precise way, ensuring the precision of bending operation and repeated positioning.

2. Its welded steel structure ensures the sheet metal brake's mechanical precision and rigidity. That is why it is so quite resistant to deformation.

3. A deflection compensation device is mounted onto the upper die of the quick-acting clamp to promote the precision of bending operation.

4. This bending machine could allow the sliding stroke to descend quickly or slowly, return quickly and stop immediately.

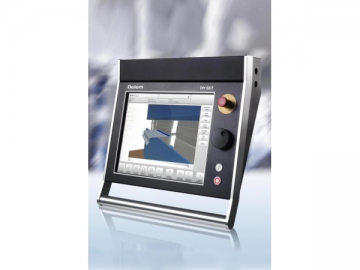

CNC System of Electro-Hydraulic Press Brake

For detailed information about this system, please click ""

1. Key Switch for Main Power

2. Power Indicator

3. Jog, Semi-auto, Full-Auto

4. E21System

5. Pump Start

6. Pump Stop Button

7. Emergency Stop

Configuration of Electro-Hydraulic CNC Press Brake

1. Hydraulic system provided by Atos(Italy);

2. Electrical system provided by Schneider(France)

3. Gear pump provided by Chengjie (Custom selection with foreign brands, such as Sumitomo);

4. Main motor provided by Shuangta (China) (Custom selection with foreign brands, such as Siemens);

5. E210 system provided by Estum(China)( Custom selection with foreign brands, such as the DA41 system provided by DELEM)

6. Ball screw provided by Taiwan supplier.

| Model | PN | Length of Table | Column Distance | Throat Depth | Stroke Length | Maximum Open Height | Main Motor Power | Dimensions |

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (kW) | L×W×H(mm) | |

| 300 | 1600 | 1250 | 170 | 90 | 195 | 3 | 1800×920×1660 | |

| 400 | 2500 | 2150 | 245 | 100 | 330 | 5.5 | 2700×1200×1950 | |

| 500 | 2500 | 2150 | 245 | 100 | 330 | 5.5 | 2700×1200×1950 | |

| 630 | 2500 | 2000 | 250 | 120 | 350 | 5.5 | 2700×1350×2120 | |

| 630 | 3200 | 2580 | 250 | 120 | 350 | 5.5 | 3400×1350×2120 | |

| 800 | 2500 | 2000 | 250 | 120 | 350 | 7.5 | 2700×1350×2120 | |

| 800 | 3200 | 2580 | 250 | 120 | 350 | 7.5 | 3400×1350×2120 | |

| 1000 | 2500 | 2000 | 300 | 130 | 400 | 7.5 | 2700×1465×2300 | |

| 1000 | 3200 | 2580 | 300 | 130 | 400 | 7.5 | 3400×1465×2300 | |

| 1000 | 4000 | 2980 | 300 | 130 | 400 | 7.5 | 4200×1465×2300 | |

| 1250 | 2500 | 2000 | 300 | 130 | 400 | 11 | 2700×1465×2300 | |

| 1250 | 3200 | 2580 | 300 | 130 | 400 | 11 | 3400×1465×2300 | |

| 1250 | 4000 | 2980 | 300 | 130 | 400 | 11 | 4200×1465×2300 | |

| 1600 | 3200 | 2580 | 340 | 150 | 450 | 11 | 3400×1620×2500 | |

| 1600 | 4000 | 2980 | 340 | 150 | 450 | 11 | 3400×1620×2500 | |

| 1600 | 5000 | 4000 | 340 | 150 | 450 | 11 | 5200×1620×2850 | |

| 1600 | 6000 | 5000 | 340 | 150 | 450 | 11 | 6200×1620×3000 | |

| 2000 | 3200 | 2580 | 340 | 150 | 450 | 15 | 3400×1620×2500 | |

| 2000 | 4000 | 2980 | 340 | 150 | 450 | 15 | 3400×1620×2500 | |

| 2000 | 5000 | 4000 | 340 | 150 | 450 | 15 | 5200×1620×2850 | |

| 2000 | 6000 | 5000 | 340 | 150 | 450 | 15 | 6200×1620×3000 | |

| 2500 | 3200 | 2580 | 400 | 200 | 500 | 18.5 | 3400×1700×2900 | |

| 2500 | 4000 | 2980 | 400 | 200 | 500 | 18.5 | 4200×1700×2900 | |

| 2500 | 5000 | 4000 | 400 | 200 | 500 | 18.5 | 5200×1700×3000 | |

| 2500 | 6000 | 5000 | 400 | 200 | 500 | 18.5 | 6200×1800×3200 | |

| 3000 | 3200 | 2580 | 400 | 200 | 520 | 22 | 3200×2000×3000 | |

| 3000 | 4000 | 2980 | 400 | 200 | 520 | 22 | 4200×2000×3000 | |

| 3000 | 5000 | 4000 | 400 | 200 | 520 | 22 | 5200×2000×3200 | |

| 3000 | 6000 | 5000 | 400 | 200 | 520 | 22 | 6200×2100×3400 | |

| 3500 | 3200 | 2580 | 400 | 250 | 570 | 22 | 3400×2000×3000 | |

| 3500 | 4000 | 2980 | 400 | 250 | 570 | 22 | 4200×2000×3000 | |

| 3500 | 5000 | 4000 | 400 | 250 | 570 | 22 | 5200×2000×3200 | |

| 3500 | 6000 | 5000 | 400 | 250 | 570 | 22 | 6200×2100×3400 | |

| 4000 | 3200 | 2580 | 400 | 250 | 580 | 22 | 3400×2000×3100 | |

| 4000 | 4000 | 2980 | 400 | 250 | 580 | 22 | 4200×2000×3100 | |

| 4000 | 5000 | 4000 | 400 | 250 | 580 | 22 | 5200×2000×3300 | |

| 4000 | 6000 | 5000 | 400 | 250 | 580 | 22 | 6200×2100×3500 | |

| 5000 | 4000 | 3000 | 500 | 300 | 640 | 37 | 4200×2300×3600 | |

| 5000 | 5000 | 4000 | 500 | 300 | 640 | 37 | 5200×2450×4000 | |

| 5000 | 6000 | 5000 | 500 | 300 | 640 | 37 | 6200×2450×4200 | |

| 6000 | 4000 | 3000 | 500 | 300 | 660 | 45 | 4200×2300×3600 | |

| 6000 | 5000 | 4000 | 500 | 300 | 660 | 45 | 5200×2450×4000 | |

| 6000 | 6000 | 5000 | 500 | 300 | 660 | 45 | 6200×2450×4200 |