CBB61s Motor Run Capacitor (Segmented Safety Film)

Product characteristics

■ Non-inductance winding structure, Segmented film

■ Excellent self-healing performance

■ Small equivalent series resistance

■ Low temperature rise

■ Stable performance, high reliability

■ Safety, fire and explosion protection

Applications

The film capacitor is mainly suitable for starting and running AC motors such as washing machine, air conditioner, electric fan, exhaust fan and single phase pump motor.

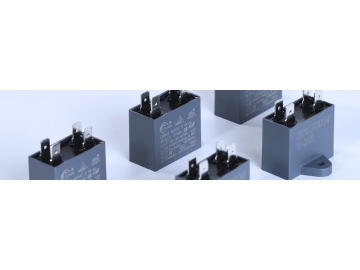

Structure

■ Metallized polypropylene film, Segmented film capacitors

■ Flame retardant engineering plastics V-0

■ Flame retardant epoxy resin V-0

■ Lead: Fast terminals such as 187# or 250#

| Safety Approvals | UL, TUV/VDE, CQC |

| Quoted Standard | GB/T3667.1, UL810, EN60252-1 |

| Type of Working | Continuous |

| Operating Class | CLASS B - 10000 hours CLASS C - 3000 hours |

| Operating Temperature (Min./Max.) | -25/70℃, -40/70℃, -40/85℃, -40/105℃ |

| Storage Temperature | -40/70℃ |

| Rated Voltage UN (a.c.) | 250~450 Volt a.c. |

| Rated Frequency fN(Hz) | 50Hz / 60Hz |

| Voltage Rise/Fall Time (max) | 15 Volt / µs |

| Maximum Permissible Voltage | 1.10 x Rated Voltage |

| Maximum Permissible Current | 1.30 x Rated Current |

| Dissipation Factor, tgδ | 20 x 10-4 at 20°C, 50 Hz |

| Class of Safety Protection | S3(P2) |

| Maximum Altitude | 2000 m |

| Capacitance Tolerance (Standard) | ± 5 % |

| Mounting | Any position |

| Case | ABS, PBT, V0 (UL94 standard) |

| Filling Resin | Self-extinguishing epoxy V0(UL94 standard) |

| Dielectric | Polypropylene film |

| Plate | Self-healing metal layer, segmented film |

| Voltage Test (Terminal to Terminal) | 2 x UN for 5 s |

| Voltage Test (Terminal to Case) | 2200 Volt for 2 s |

| Insulation Resistance (20℃) | Between terminals≥2000MΩ .μF (500Vdc,60s) |

| Leakage – Clearance in air between parts under voltage | ≥ 5mm |

| Vibration Test | IEC 60068-2-6 |

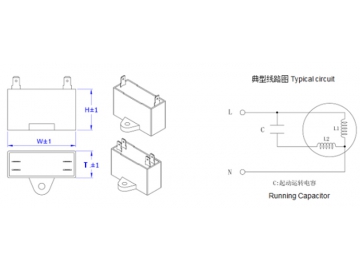

| Rated Cap. | 250/300VAC | 400/450VAC(C) | 450VAC(B) | ||||||

| W | H | T | W | H | T | W | H | T | |

| 1.0μF | 32 | 22 | 12 | 37 | 22 | 12 | 37 | 24 | 13.5 |

| 1.2μF | 32 | 22 | 12 | 37 | 23 | 12 | 37 | 25 | 14 |

| 1.5μF | 32 | 22 | 12 | 37 | 24 | 13 | 37 | 27 | 16 |

| 2.0μF | 32 | 22 | 12 | 37 | 27 | 15 | 37 | 28 | 17 |

| 2.2μF | 37 | 22 | 12 | 37 | 27 | 16 | 37 | 29 | 18.5 |

| 2.5μF | 37 | 22 | 12 | 37 | 28 | 17 | 37 | 31 | 19 |

| 3.0μF | 37 | 24 | 13.5 | 37 | 29 | 19 | 47 | 29 | 19 |

| 3.5μF | 37 | 25 | 14 | 47 | 28 | 17 | 47 | 31 | 19.5 |

| 4.0μF | 37 | 25 | 15 | 47 | 29 | 18.5 | 47 | 33 | 20.5 |

| 4.5μF | 37 | 27 | 15 | 47 | 30 | 19 | 47 | 33 | 22 |

| 5.0μF | 37 | 27 | 16 | 47 | 31 | 20 | 47 | 35 | 25 |

| 5.5μF | 37 | 28 | 17 | 47 | 33 | 22 | 47 | 35 | 25 |

| 6.0μF | 37 | 29 | 18.5 | 47 | 33 | 22 | 47 | 37 | 26 |

| 6.5μF | 37 | 31 | 19 | 47 | 35 | 24 | 47 | 38 | 26 |

| 7.0μF | 37 | 31 | 20 | 47 | 35 | 24 | 47 | 38 | 28 |

| 7.5μF | 37 | 31 | 20 | 47 | 38 | 26 | 47 | 40 | 28 |

| 8.0μF | 37 | 28 | 17 | 47 | 38 | 26 | 47 | 40 | 30 |

| 9.0μF | 37 | 31 | 20 | 47 | 38 | 28 | 57 | 40 | 28 |

| 10.0μF | 47 | 31 | 20 | 47 | 40 | 28 | 57 | 40 | 30 |

| 12.0μF | 47 | 33 | 20.5 | 57 | 40 | 28 | 57 | 45 | 30 |

| 12.5μF | 47 | 33 | 22 | 57 | 40 | 30 | 57 | 45 | 35 |

| 13.0μF | 47 | 33 | 22 | 57 | 40 | 30 | 57 | 45 | 35 |

| 14.0μF | 47 | 35 | 24 | 57 | 42 | 30 | 57 | 50 | 35 |

| 15.0μF | 47 | 35 | 25 | 57 | 45 | 30 | 57 | 50 | 35 |

| 18.0μF | 47 | 38 | 26 | 57 | 45 | 35 | -- | -- | -- |

| 20.0μF | 47 | 40 | 28 | 57 | 50 | 35 | -- | -- | -- |

| 22.0μF | 47 | 40 | 30 | -- | -- | -- | -- | -- | -- |

| 25.0μF | 57 | 38 | 28 | -- | -- | -- | -- | -- | -- |

| 27.5μF | 57 | 40 | 30 | -- | -- | -- | -- | -- | -- |

| 30.0μF | 57 | 42 | 30 | -- | -- | -- | -- | -- | -- |

Schematic and Typical Circuit Diagrams

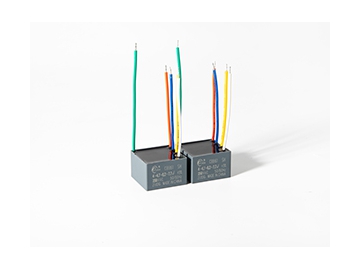

Features

1. Electrician polypropylene film as a medium, zinc-aluminum metallized layer as an electrode, high-quality engineering plastic case, flame retardant epoxy resin for its encapsulating;

2. PVC electronic wire lead-out, strong universality, flexible assembling.

Our Advantages

1. We have supplied capacitors to air conditioning industry for more than 6 years with minimal complaints and one of the lowest replacement rates.

2. Our product certification is complete: (CQC, UL, TUV), allowing us to sell our products to any UL or TUV approved country.

3. Imported materials and stable performance.