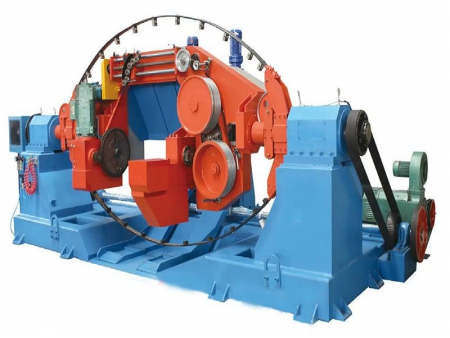

Tubular Stranding Machine, JLG Series

Request a Quote

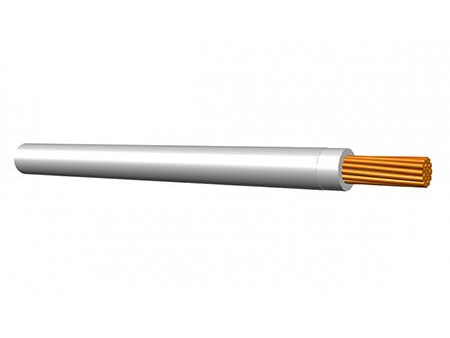

Tubular stranding line for manufacturing steel strands, copper and aluminum conductors

Tubular Stranding Machine: Smooth and Quiet Stranding Solution for Steel Strands and Conductors

Our tubular stranding machine is designed for the efficient stranding of steel strands, copper conductors, aluminum conductors, steel core aluminum conductors, and steel wire ropes. This versatile stranding machine can also be used for insulating cable core stranding and the production of certain control cables.

Features

- Solid base and seamless steel tube structure for stability and low noise

- Smooth and convenient speed control with variable speed motors

- Variable speed gearbox for precise pitch control and low labor intensity

- Equipped with safety measures like automatic wire-break detection and door-open stoppage

Specifications

| Model | JLG 500 | JLG 630 |

| Single wire diameter | Cu: Ø 1.2-5.0 mm Al: Ø 1.5-5.0 mm | Cu: Ø 1.2-5.0 mm Al: Ø 1.5-5.0 mm |

| Max finish wire diameter | Ø 21 mm | Ø 21 mm |

| Max rotation speed | 500 rpm | 500 rpm |

| Stranding pitch | 40-448 | 40-448 |

| Max line speed | 150 m/min | 150 m/min |

| Bobbin specification | PND500 | PND630 |

| Capstan wheel | 1250 mm | 1250 mm |

| Take-up bobbin | PN1600 | PN1600 |

| Height of center | 850 mm | 850 mm |

Details

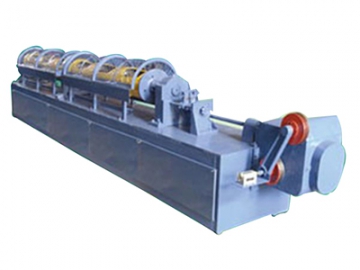

Pay-Off

- Pneumatic release and clamp, convenient loading and unloading of wire bobbins

- Manual adjustment of mechanical friction tension control on the operator side

Take-Up

- End-shaft structure with electrically controlled clamping and release of wire bobbins

- Electric lifting and clamping with safety protection mechanism

- Wire arrangement and speed control through time relays, providing high thrust and easy adjustment

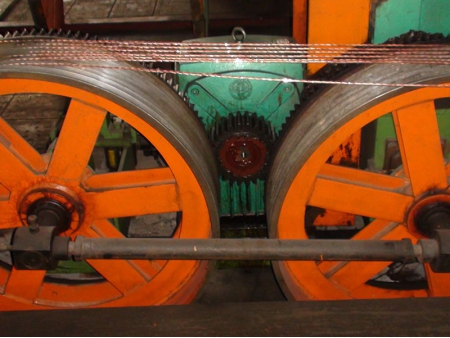

Double Wheel Capstan

- Dual-driven wheels with natural wire distribution to prevent conductor damage

- Pneumatic pressure system to prevent cable slippage during startup

- Excellent synchronization and pulling force

- Safety overload protection with pin coupling

Meter Counter

- Non-contact electronic meter counter for accurate and reliable measurements

- Mechanical meter counter included

Control System

- Siemens PLC control for smooth operation and reliable performance

- All technical parameters adjustable via the touchscreen interface, with the ability to store production process parameters

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos