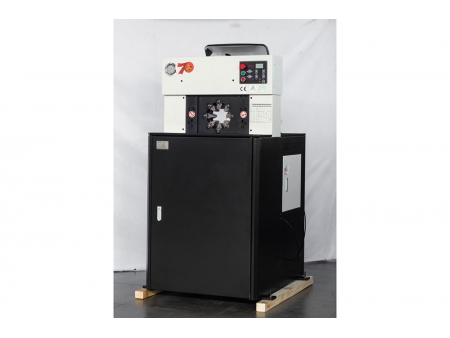

YONG-FENG Y160 Uxtra Thin Radial Hydraulic Hose Crimping Machine

Application

The crimp force of YONG-FENG Y160 uxtra thin radial hydraulic hose crimping machine is 2800kN, with a crimp range of 4~124mm and 11 sets of standard dies. YONG-FENG Y160 crimpers are widely used for crimping high-pressure fuel pipes, industrial hoses, water hoses, automobile air bags and ropes, metal pipes and steel tubes etc.

Max. inner diameter

Hoses with 2 braided wires: 2 ½"

Hoses with 4 spiral wires: 2 ½"

Hoses with 6 spiral wires: 2"

| Crimp head material | FORGE STEEL |

| Crimp range | 4-124mm |

| Hose size | 2 ½”, 6SN |

| Passing diameter | 152mm |

| Opening diameter | 152mm |

| Opening | 65mm |

| System pressure | 31.5Mpa |

| Crimp force | 2800kN |

| Drive | 5.5kw |

| Standard voltage | Customized |

| Control | Digital CNC with display |

| Standard dies | 11 sets |

| Weight | 1230 kg |

| L x W x H | 860*990*1550 mm |

| Dies Quickchange tool | Included |

| Foot Pedal | Included |

| Special Dies Customized | Included |

| Instruction Book | Included |

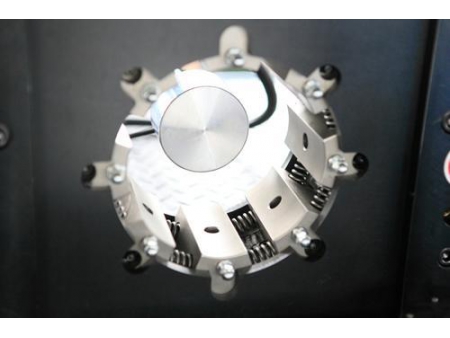

Details

The oil cylinder cover, oil tank and piston rod are made of 40 chromium, with a surface hardness of HRC26-30 and an operation layer hardness of HRC59-63. The hardened layer is 2mm thick.

The 40 chromium is high pressure resistant and tear resistant with great impact absorbing and carrying capacity. Therefore, the oil tank and piston rod are more durable.

Operation

The oil pump is immersed in hydraulic oil inside the oil tank for cooling and silence. The oil pump is driven using an electric motor and the hydraulic oil is pumped out, pushing the plunger in the oil tank. As a result, the die set compresses in a radial direction and crimps the hose connector. When the compression amount reaches the predetermined value, the compression will automatically stop. Then the magnetic reversing valve switches the direction and the plunger moves backwards. As a result, the die set expands and the hose crimping process is finished.