TAPM2020 CNC Angle Line (Including CNC Structural Steel Punching, Marking, Shearing Machine)

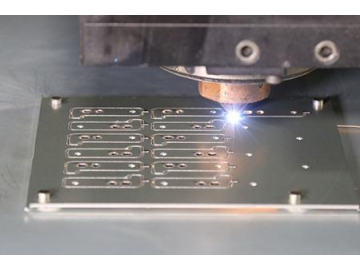

Our TAPM2020 CNC metal punching, marking, shearing machine for angle steels is a CNC production system specially designed for the electrical, telecommunications, and angle steel tower industries. This equipment efficiently achieves automatic marking, punching and cutting functions for angle steel.

When designing our equipment, we consider both safety and ergonomics. However, safety does not always mean efficiency, which is why our machines are all in compliance with CE regulations and standards for both functionality and security.

Our enhanced CNC angle line guarantees the operating staff’s safety, and also achieve a number of functions during the cycle of operation. Due to this, uncertain factors that come with equipment like this are largely reduced, and the productivity can be maximally performed.

Features

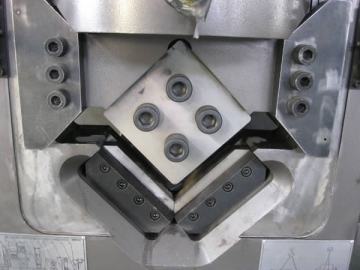

1. The marking unit has a brand new closed frame featuring excellent rigidity and the marking stadis can be set randomly.

2. Labor intensity is significantly reduced. For example, the marking, punching and cutting are all automatically conducted, and the finished product is pneumatically rotated and unloaded.

3. This enhanced CNC punching equipment can adapt single steel with bigger curvatures with its material salver device and material press device.

4. Our CNC marking equipment supports both Chinese and English languages, making it easy to operate. It can also display work piece figures easily.

5. Programming is simple, and the operator can enter the work piece information, including dimension, bore diameter, stadia and quantity.

6. This CNC machinery for angle steel can directly use the data gathered from the sample software.

7. CNC technology is used in this automatic angle steel machining equipment. Its feeding system is controlled by the servo motor. Due to this, it has a high efficiency and can generate work pieces with stable precision.

8. Our CNC shearing equipment can process material with fixed-lengths without cutting.

9. It has a self-diagnostic function for finding faults

10. The imported hydraulic parts, pneumatic components and electrical elements of our CNC angle line all have a great stability rate.

Parameters of TAPM2020 CNC Processing Equipment| Model | |

| Processing range(mm) | From 63×63×4 to 200×200×20 (Q420) |

| Max. punching capacity (diameter × thickness) (mm) | Φ26×20 |

| Punching force(kn) | 1,200 |

| Marking force(kn) | 1,030 |

| Shearing force(kn) | 2,100 |

| Max. length of workblank (m) | 14 |

| Max. length of finished product (m) | 14 |

| Number of punching head on each side | 3 |

| Number of character marking group | 4 |

| Number of character in each marking group | 15 |

| Dimension of character (mm) | 14×10×19 |

| Adjustable range of stadia (mm) | From 20 to 170 (Stepless) |

| Number of CNC axes | 3 |

| Cutting mode | Dual blades cutting |

| Max. feeding speed of angle steel (m/min) | 40 |

| Processing precision | In accordance with GB2694-81 |

| Programming mode | Keyboard input, RS232 interface, floppy disk and USB interface |

| Dimension (mm) | 32,000×7,000×3,000 |

| Weight (kg) | 17,000 |