| Model | | | |||

| Power Supply | AC 380V 50Hz three-phase N PE | ||||

| Maximum Power | 11 | 18 | 21 | ||

| Operation Environment | 5℃~ 35℃/≤85%RH | ||||

| Performance | Temperature and Relative Humidity Range | -70℃~ 120℃ | |||

| 15℃~ 85℃ 20%~95%RH | |||||

| Dew Point Range | 4°℃~ 84℃ | ||||

| Model Heating Rate"2 | 2.5℃/min | 2.5℃/min | 2℃/min | ||

| Model Cooling Rate"2 | 1.8℃/min | 1.8°C/min | 2℃/min | ||

| Pressure Range | 1KPa~1bar | ||||

| Pressure Fluctuation | ≤±2 Kpa(1bar~40KPa)/≤±5%(40KPa~2KPa)/≤0.1KPa(≤2KPa) | ||||

| Pressure Falling Down Time | within 30 minutes | ||||

| Inspection Window | multiplayer glasses with conducting film heating, size W240mmxH310mm | ||||

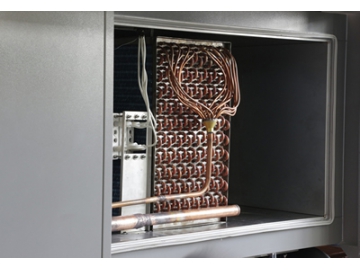

| Condenser | air-cooled condenser | ||||

| Interior Capacity (L) | 150 | 544 | 1040 | ||

| Internal Dimensions (mm) | W | 600 | 800 | 1010 | |

| D | 500 | 800 1010 | 1010 | ||

| H | 500 850 1020 | 850 | 1020 | ||

| External Dimensions (mm) | W | 960 | 1200 | 1430 | |

| D | 2640 | 2855 | 3455 | ||

| H | 1900 | 2490 | 2290 | ||

| |||||

Our vacuum test chambers are primarily used to conduct environmental adaptability and reliability tests on electronic components under low pressure, high temperature, low temperature, or combined conditions. They also facilitate the measurement of electrical performance when the test specimen is powered.

The vacuum system consists of two integral components: the vacuum measurement system and the vacuum acquisition unit. The vacuum measurement system measures and controls the vacuum level using pressure sensors. The vacuum data is converted into linear electrical signals and can be directly displayed and controlled by the equipment controller.