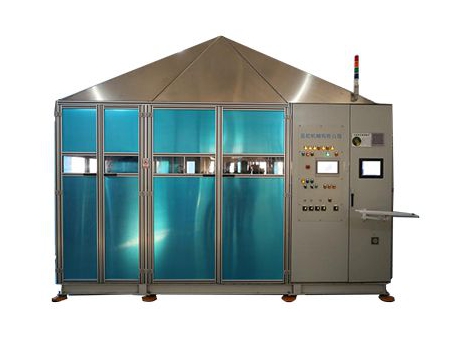

Rubber Seal Forming Machine

Request a Quote

JCX-X-I

JCX-X-II

JCX-X-III

JCX-X-I: Gantry structure with profile correction

JCX-X-II: One set of vertical wheels, two sets of horizontal wheels

JCX-X-III: Y-profile wheel

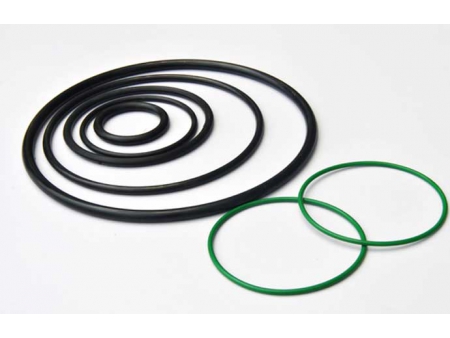

Applications

Rubber seal forming machine is used for the final forming of rubber sealing strips.

Rubber Seal Forming Machine (Gantry structure)

| Model | |

| Dimensions | L2855mm×W645mm×H1400mm (subject to final design drawings) |

| Power Transmission | 1 reducer motor drives two sets of gears, and the upper and lower gears output two sets of power. |

| Structure | The power shaft is connected to 3 groups of forming mechanisms through universal joint couplings. |

| Forming Mechanism | 3 sets of forming mechanisms (without forming wheels), with a gantry structure. Both upper and lower forming wheel shafts have power, and the material of the shafts is 40Cr with high-frequency quenching. |

| Tooling Mold | 3 sets of forming mechanisms (without forming wheels) are installed on a 20mm thick base plate. The base plate has ball bearings for easy replacement, and the upper shaft adjustment is mechanically controlled with digital display adjustment. |

| Adjustment Range | The center adjustment range of the shaft is 70-110mm. |

| Alarm | Sound-light alarms are triggered in case of abnormal frequency converter, transmission motor, material breakage, or door switch. |

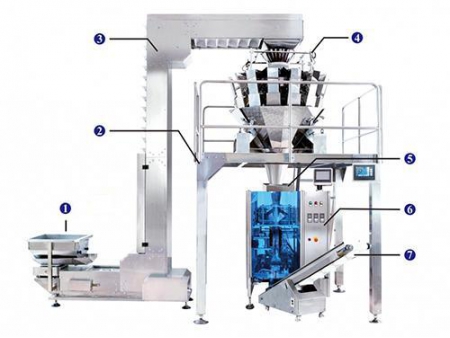

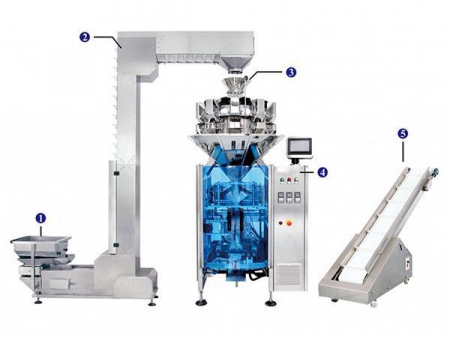

Rubber Seal Forming Machine (vertical horizontal wheels)

| Model | |

| Dimensions | L2600×W880×H1170mm (subject to final design drawings) |

| Drive Motor | Vertical forming wheel group: variable frequency motor. Horizontal forming wheel group: variable frequency motor. Vertical traction: variable frequency motor. |

| Transmission Speed | 2~35m/min, frequency conversion speed control |

| Speed Control | Equipped with a swing rod potentiometer for automatic adaptation to the line speed. |

| Vertical Forming Wheel Group | 1 pair, the upper wheel is driven by an independent motor and can be adjusted up to 20 degrees. The lower wheel is passive and adjustable in the forward and backward directions. (The vertical wheel group undergoes quenching treatment but not surface hardening. It needs to be adjusted and undergo self-quenching and surface treatment according to requirements.) |

| Horizontal Forming Wheel Group | 2 pairs of wheels, each pair can be individually adjusted in the forward and backward as well as up and down directions. It is driven by one motor. (The horizontal forming wheel group is finished with quenching and surface treatment.) |

| Vertical Traction | 1set, driven by one independent motor |

| Guide Plate | An adjustable-width guide plate at the entrance, with a pressure roller. |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos