Indirect Contact Dryer

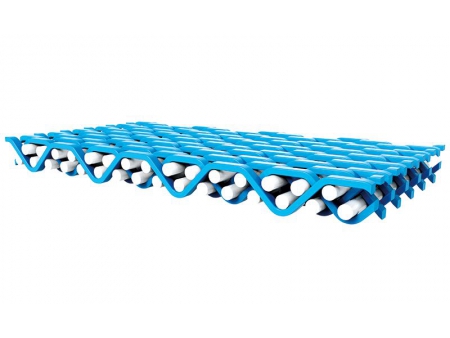

The indirect contact dryer is suitable for drying or cooling pastes, particles and powders in a slurry state. The special stirring blade features high heat transferring efficiency, providing a self-cleaning function.

Hollow chock shaped blades are fitted on the hollow shaft where the heat media flows through the blade. The temperature range of the blade dryer is -40 ℃ to 320 ℃.

Applications

The large heating area in the drying unit dries the material very fast and it is suitable for a wide variety of different industrial applications.

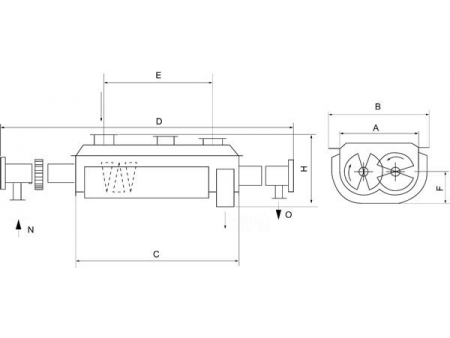

| Specification | QJ3 | QJ9 | QJ13 | QJ18 | QJ29 | QJ41 | QJ52 | QJ68 | QJ81 | QJ95 | QJ110 |

| heat transferring area m2 | 3 | 9 | 13 | 18 | 29 | 41 | 52 | 68 | 81 | 95 | 110 |

| effective volume m3 | 0.06 | 0.32 | 0.59 | 1.09 | 1.85 | 2.8 | 3.96 | 5.21 | 6.43 | 8.07 | 9.46 |

| range of rotating speed r.m.p | 15-30 | 10-25 | 10-25 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 5-15 | 5-15 | 5-10 |

| power kw | 2.2 | 4 | 5.5 | 7.5 | 11 | 15 | 30 | 45 | 55 | 75 | 95 |

| width of vessel mm | 306 | 584 | 762 | 940 | 1118 | 1296 | 1474 | 1652 | 1828 | 2032 | 2210 |

| total width mm | 736 | 841 | 1066 | 1320 | 1474 | 1676 | 1854 | 2134 | 1186 | 2438 | 2668 |

| length of vessel mm | 1956 | 2820 | 3048 | 3328 | 4114 | 4724 | 5258 | 5842 | 6020 | 6124 | 6122 |

| total length mm | 2972 | 4876 | 5486 | 5918 | 6808 | 7570 | 8306 | 9296 | 9678 | 9704 | 9880 |

| distance of material inlet & outlet mm | 1752 | 2540 | 2768 | 3048 | 3810 | 4420 | 4954 | 5384 | 5562 | 5664 | 5664 |

| height of center mm | 380 | 380 | 534 | 610 | 762 | 915 | 1066 | 1220 | 1220 | 1220 | 1220 |

| total height mm | 762 | 838 | 1092 | 1270 | 1524 | 1778 | 2032 | 2362 | 2464 | 2566 | 2668 |

| steam inlet "n" ( inch) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 11/2 | 11/2 | 11/2 | 11/2 | 2 |

| water outlet "o" (inch) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 11/2 | 11/2 | 11/2 | 11/2 | 2 |

Features

1. The heat consumption of blade is low: It consumes 1.2 kg of steam to evaporate 1kg of water to dry slurry materials.

2. The cost of the blade dryer is low: Efficiency is high and processing time is shortened.

3. The wide range of materials can be processed: Heat sensitive material and the materials to be processed under high temperature might be processed by applying different heating sources.

4. Low pollution: solvents can be easily collected and recirculated, especially when operating in a closed system.

5. Steady operation: The material particles fully contact the heat transferring surface for uniform drying.