CNC Hydraulic Press Brake

TAM-S Series

TAM-S Series

TAM-S series CNC hydraulic press brake is equipped with a high-precision quick clamping device, and a stable backgauge system. This significantly reduces labor intensity, improves production efficiency, and ensures high-quality bending accuracy. Additionally, this bending machine adopts a hydraulic integrated system from a reputable German brand, greatly reducing the failure rate.

- Sheet bending

- Machine parts manufacturing

- Automotive manufacturing process

- Electronic components manufacturing

- Furniture manufacturing process

- Steel tube bending

(bending capacity: 80 to 320 ton)

| Model | Force (kN) | A | B | C | D | E | Main power (kW) | Oil volume (L) | X axis stroke (mm) | R axis stroke (mm) | Max. speed (mm/s) | Dimensions (L*W*H) (mm) | Weight (kg) | ||

| Max. bending length (mm) | Distance between uprights (mm) | Throat depth (mm) | Cylinder stroke (mm) | Opening height (mm) | Approaching speed | Working speed | Returning speed | ||||||||

| 800 | 2500 | 2000 | 300 | 160 | 425 | 7.5 | 200 | 450 | 200 | 200 | 0-15 | 200 | 2990*1470*2410 | 6100 | |

| 1000 | 3200 | 2700 | 400 | 200 | 475 | 12.4 | 200 | 450 | 200 | 220 | 0-15 | 180 | 3700*1550*2645 | 7800 | |

| 1100 | 2500 | 2000 | 400 | 225 | 500 | 12.4 | 200 | 600 | 200 | 220 | 0-15 | 180 | 3010*1670*2720 | 7800 | |

| 1100 | 3200 | 2700 | 400 | 225 | 500 | 12.4 | 200 | 600 | 200 | 220 | 0-15 | 180 | 3710*1670*2720 | 9000 | |

| 1100 | 4100 | 3600 | 500 | 225 | 500 | 12.4 | 200 | 600 | 200 | 220 | 0-15 | 180 | 4610*1770*2720 | 10900 | |

| 1300 | 2500 | 2000 | 400 | 225 | 500 | 12.4 | 200 | 600 | 200 | 200 | 0-15 | 160 | 3010*1670*2720 | 7800 | |

| 1300 | 3200 | 2700 | 400 | 225 | 500 | 12.4 | 200 | 600 | 200 | 200 | 0-15 | 160 | 3710*1670*2720 | 9000 | |

| 1300 | 4100 | 3600 | 500 | 225 | 500 | 12.4 | 200 | 600 | 200 | 200 | 0-15 | 160 | 4610*1770*2720 | 11300 | |

| 1300 | 5100 | 4600 | 400 | 225 | 500 | 17.8 | 200 | 600 | 200 | 180 | 0-15 | 130 | 5610*1820*2960 | 15200 | |

| 1300 | 6100 | 5600 | 400 | 225 | 500 | 17.8 | 200 | 600 | 200 | 180 | 0-15 | 130 | 6610*1820*3110 | 17700 | |

| 1700 | 2500 | 2000 | 400 | 225 | 500 | 17.8 | 200 | 600 | 200 | 200 | 0-15 | 160 | 3030*1680*2720 | 8700 | |

| 1700 | 3200 | 2700 | 400 | 225 | 500 | 17.8 | 200 | 600 | 200 | 200 | 0-15 | 160 | 3730*1680*2720 | 10100 | |

| 1700 | 4100 | 3600 | 500 | 225 | 500 | 17.8 | 200 | 600 | 200 | 200 | 0-15 | 160 | 4630*1790*2720 | 12100 | |

| 1700 | 5100 | 4600 | 400 | 225 | 500 | 17.8 | 200 | 600 | 200 | 160 | 0-15 | 110 | 5630*1800*2960 | 17000 | |

| 1700 | 6100 | 5600 | 400 | 225 | 500 | 17.8 | 200 | 600 | 200 | 160 | 0-15 | 110 | 6630*1800*3160 | 20000 | |

| 2300 | 2500 | 2000 | 420 | 225 | 500 | 21.4 | 400 | 600 | 200 | 140 | 0-13 | 150 | 3040*1700*2720 | 10500 | |

| 2300 | 3200 | 2700 | 420 | 225 | 500 | 21.4 | 400 | 600 | 200 | 140 | 0-13 | 150 | 3750*1700*2720 | 11800 | |

| 2300 | 4100 | 3600 | 420 | 225 | 500 | 21.4 | 400 | 600 | 200 | 140 | 0-13 | 150 | 4650*1700*2720 | 13700 | |

| 2300 | 5100 | 4600 | 420 | 225 | 500 | 21.4 | 400 | 600 | 200 | 130 | 0-13 | 130 | 5640*1880*3060 | 18600 | |

| 2300 | 6100 | 5600 | 420 | 225 | 500 | 21.4 | 400 | 600 | 200 | 130 | 0-13 | 130 | 6640*1880*3210 | 21600 | |

| 2500 | 2500 | 2000 | 400 | 250 | 525 | 21.4 | 400 | 600 | 200 | 130 | 0-13 | 130 | 3050*1920*2975 | 11700 | |

| 2500 | 3200 | 2700 | 400 | 250 | 525 | 21.4 | 460 | 600 | 200 | 130 | 0-13 | 130 | 3750*1920*2975 | 14000 | |

| 2500 | 4100 | 3600 | 400 | 250 | 525 | 21.4 | 460 | 600 | 200 | 130 | 0-13 | 130 | 4650*1920*2975 | 16000 | |

| 2500 | 5100 | 4600 | 400 | 250 | 525 | 21.4 | 460 | 600 | 200 | 120 | 0-13 | 110 | 5650*1920*3125 | 21200 | |

| 2500 | 6100 | 5600 | 400 | 250 | 525 | 21.4 | 460 | 600 | 200 | 120 | 0-13 | 110 | 6650*1920*3325 | 24600 | |

| 3200 | 3200 | 2700 | 400 | 300 | 575 | 25.2 | 460 | 600 | 200 | 100 | 0-13 | 110 | 3930*2110*3205 | 17700 | |

| 3200 | 4100 | 3600 | 400 | 300 | 575 | 25.2 | 460 | 600 | 200 | 100 | 0-13 | 110 | 4830*2110*3205 | 20300 | |

| 3200 | 5100 | 4600 | 400 | 300 | 575 | 25.2 | 460 | 600 | 200 | 90 | 0-13 | 90 | 5830*2150*3690 | 26100 | |

| 3200 | 6100 | 5600 | 400 | 300 | 575 | 25.2 | 460 | 600 | 200 | 90 | 0-13 | 90 | 6830*2150*3855 | 30400 | |

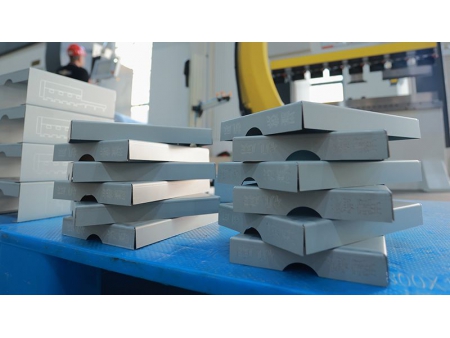

- Quick Vertical Loading and Unloading Quick Clamps

Equipped with precise fast fixtures, toolings can be installed and replaced in both directions from the bottom and lateral two-way of the fixture, which can effectively reduce the tooling replacement time, improve production efficiency, and have a greater load-bearing capacity.

- Stable Backgauge Structure

Double linear guide structure ensures the best positioning accuracy. Multi-stage stop design increases the positioning range.

- Easy Backgauge structure

Standard for 30-50 ton model

Novel and unique design structure, multi-stage stop design, extended positioning range - Throat deformation compensation device

Ensures bending accuracy and effectively prevents collision interference with non-standard workpieces through the detection unit.

- Mechanical compensation device

Controlled by CNC system to ensure the bending accuracy is always stable.

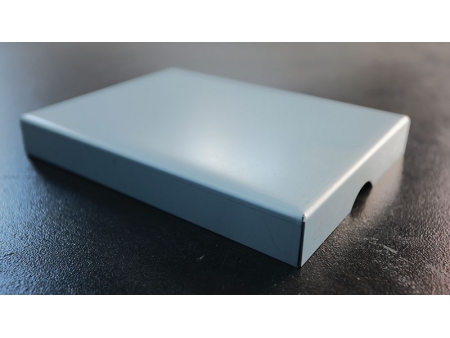

- High-quality bending tooling

Integral hardened for durability and long-lasting performance.

- High-performance hydraulic System

It is imported from Germany with higher frequency response and lower failure rate, resulting in smoother and faster machine operation.

- Fuel storage tank made of oil-resistant special materials

- CNC system: Switzerland Cybelec CT12

12 inch touch screen

- Italy Laser Protection Light Curtain

- Sheet Thickness Measuring Device

- Angle Monitoring and Correction Device

- X-R-Z1-Z2 4 Axes Backgauge System

- X-R-Z1-Z2-X' 5 Axes Backgauge System

- X1-X2-R1-R2-Z1-Z2 6 Axes Backgauge System

- Servo Replacement of Tooling Slots

- Bending Aids System

- Pneumatic Lifting Pallet

- Pneumatic Rear Pallet Device

The pneumatic brush-assisted backgauge is suitable for thin sheet metal processing.

- Italy ESA S640

- Italy ESA S860W

- Switzerland Cybelec VT-19

- Switzerland Cybelec VT-15