CNC Heavy Duty Hybrid Press Brake

UBB-D Series

UBB-D Series

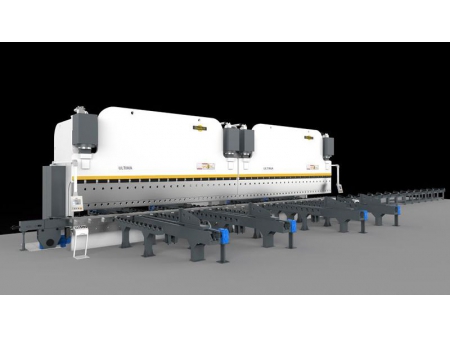

UBB-D series heavy duty hybrid press brake adopts DeraTech's proprietary oil-electric hybrid drive system (Patent No: 201721645295.3), which is exclusively and globally applied for the first time in large-tonnage heavy-duty bending machines. This oil-electric hybrid drive system has the advantages of energy saving, high efficiency, environmental friendliness, and fast response.

- Energy-saving: The servo motor only consumes electricity when bending the sheet metal, saving 50%-70% of power compared to traditional bending machines.

- Fuel-efficient: It requires only 1/4 of the hydraulic oil volume used in traditional CNC bending machines while maintaining lower temperature rise, effectively protecting the performance of hydraulic components.

- Equipped with specially developed structural oil cylinders (Patent No: 201721644984.2): achieves smooth and high-speed operation of the slide, greatly improving machine efficiency.

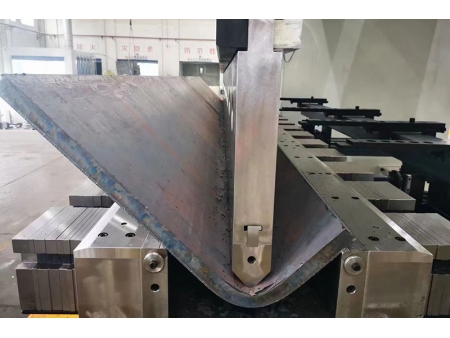

- Insert structure for lower die: The lower die slot can be adjusted from 50mm to 200mm, providing quick and convenient operation.

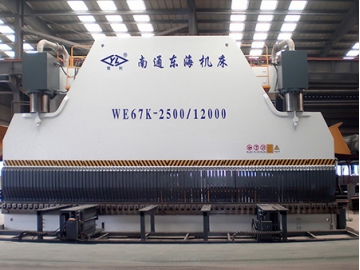

UBB800-7000D

UBB800-7000D

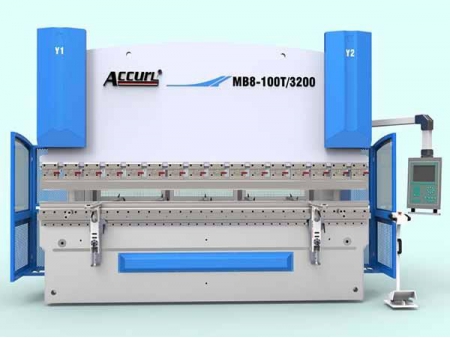

Hybrid Press Brake UBB-400/6000D

UBB-400/6000D

Hybrid Press Brake

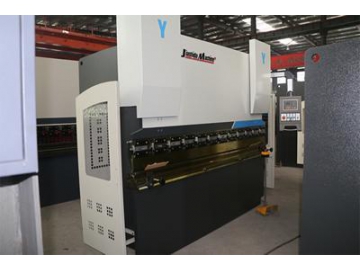

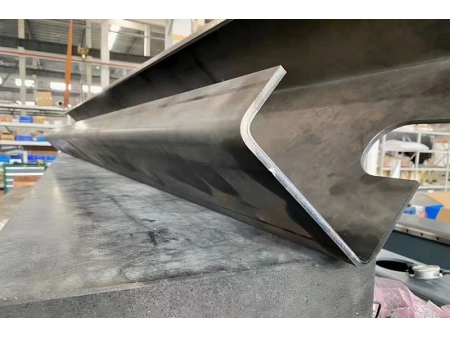

Heavy-duty press brake is applicable for:

- sheet bending

- steel structure manufacturing

- shipbuilding presses

- steel bridge fabrication

- heavy equipment manufacturing

- pressure vessel manufacturing

(bending capacity: 400 to 800 ton)

| Model | Force (kN) | A | B | C | D | E | Oil volume (L) | Main power (kW) | X axis stroke (mm) | Max. speed (mm/s) | Dimensions (L*W*H) (mm) | Weight (kg) | ||

| Max. bending length (mm) | Distance between uprights (mm) | Throat depth (mm) | Cylinder stroke (mm) | Opening height (mm) | Length | Width | Height | |||||||

| 4000 | 3200 | 2600 | 450 | 300 | 600 | 2×120 | 2×8.5 | 1000 | 110 | 0~8 | 110 | 3460*2350*3600 | 24500 | |

| 4000 | 4000 | 3200 | 450 | 300 | 600 | 2×120 | 2×8.5 | 1000 | 110 | 0~8 | 110 | 4260*2350*3600 | 27300 | |

| 4000 | 5000 | 4000 | 450 | 300 | 600 | 2×120 | 2×8.5 | 1000 | 100 | 0~8 | 100 | 5260*2350*4700 | 33500 | |

| 4000 | 6000 | 5000 | 450 | 300 | 600 | 2×120 | 2×8.5 | 1000 | 100 | 0~8 | 100 | 6260*2350*5000 | 39000 | |

| 4000 | 7000 | 6000 | 450 | 300 | 600 | 2×120 | 2×8.5 | 1000 | 100 | 0~8 | 100 | 7260*2350*5500 | 44000 | |

| 4000 | 8000 | 7000 | 450 | 300 | 600 | 2×120 | 2×8.5 | 1000 | 100 | 0~8 | 100 | 8260*2350*5900 | 50000 | |

| 5000 | 3200 | 2600 | 500 | 300 | 600 | 2×150 | 2×12.4 | 1000 | 90 | 0~7 | 90 | 3480*2580*4600 | 31500 | |

| 5000 | 4000 | 3200 | 500 | 300 | 600 | 2×180 | 2×12.4 | 1000 | 90 | 0~7 | 90 | 4260*2580*4700 | 35000 | |

| 5000 | 5000 | 4000 | 500 | 300 | 600 | 2×180 | 2×12.4 | 1000 | 90 | 0~7 | 90 | 5260*2580*4900 | 39000 | |

| 5000 | 6000 | 5000 | 500 | 300 | 600 | 2×180 | 2×12.4 | 1000 | 90 | 0~7 | 90 | 6260*2580*5200 | 45000 | |

| 5000 | 7000 | 6000 | 500 | 300 | 600 | 2×180 | 2×12.4 | 1000 | 90 | 0~7 | 90 | 7260*2580*5500 | 50000 | |

| 5000 | 8000 | 7000 | 500 | 300 | 600 | 2×180 | 2×12.4 | 1000 | 90 | 0~7 | 90 | 8260*2580*5900 | 57000 | |

| 6000 | 4000 | 3200 | 550 | 300 | 600 | 2×180 | 2×17.8 | 1000 | 90 | 0~7 | 90 | 4260*3530*4950 | 43000 | |

| 6000 | 5000 | 4000 | 550 | 300 | 600 | 2×180 | 2×17.8 | 1000 | 90 | 0~7 | 90 | 5260*3530*5050 | 48000 | |

| 6000 | 6000 | 5000 | 550 | 300 | 600 | 2×180 | 2×17.8 | 1000 | 90 | 0~7 | 90 | 6260*3530*5200 | 54000 | |

| 6000 | 7000 | 6000 | 600 | 350 | 700 | 2×180 | 2×17.8 | 1000 | 90 | 0~7 | 90 | 7260*3530*5600 | 63000 | |

| 6000 | 8000 | 7000 | 600 | 350 | 700 | 2×180 | 2×17.8 | 1000 | 90 | 0~7 | 90 | 8260*3530*6000 | 71000 | |

| 7000 | 4000 | 3200 | 650 | 350 | 700 | 2×180 | 2×17.8 | 1000 | 90 | 0~7 | 90 | 4260*3600*5300 | 49000 | |

| 7000 | 5000 | 4000 | 650 | 350 | 700 | 2×180 | 2×17.8 | 1000 | 90 | 0~7 | 90 | 5260*3600*5500 | 55000 | |

| 7000 | 6000 | 5000 | 650 | 350 | 700 | 2×180 | 2×17.8 | 1000 | 90 | 0~7 | 90 | 6260*3600*5700 | 62000 | |

| 7000 | 7000 | 6000 | 650 | 350 | 700 | 2×180 | 2×17.8 | 1000 | 90 | 0~7 | 90 | 7260*3600*5900 | 70000 | |

| 7000 | 8000 | 7000 | 650 | 350 | 700 | 2×180 | 2×17.8 | 1000 | 90 | 0~7 | 90 | 8260*3600*6200 | 79000 | |

| 8000 | 4000 | 3200 | 700 | 400 | 800 | 2×220 | 2×21.4 | 1000 | 90 | 0~7 | 90 | 4260*3650*5700 | 62000 | |

| 8000 | 5000 | 4000 | 700 | 400 | 800 | 2×220 | 2×21.4 | 1000 | 90 | 0~7 | 90 | 5260*3650*5900 | 69000 | |

| 8000 | 6000 | 5000 | 700 | 400 | 800 | 2×220 | 2×21.4 | 1000 | 90 | 0~7 | 90 | 6260*3650*6000 | 76000 | |

| 8000 | 7000 | 6000 | 700 | 400 | 800 | 2×220 | 2×21.4 | 1000 | 90 | 0~7 | 90 | 7260*3650*6200 | 84000 | |

| 8000 | 8000 | 7000 | 700 | 400 | 800 | 2×220 | 2×21.4 | 1000 | 90 | 0~7 | 90 | 8260*3650*6600 | 94000 | |

| 10000 | 5000 | 4000 | 800 | 400 | 950 | 2×420 | 2×25.2 | 1000 | 70 | 0~7 | 70 | 5350*4100*6300 | 89000 | |

| 10000 | 6000 | 5000 | 800 | 400 | 950 | 2×420 | 2×25.2 | 1000 | 70 | 0~7 | 70 | 6350*4100*6400 | 99000 | |

| 10000 | 7000 | 6000 | 800 | 400 | 950 | 2×420 | 2×25.2 | 1000 | 70 | 0~7 | 70 | 7350*4100*6600 | 109000 | |

| 10000 | 8000 | 7000 | 800 | 400 | 950 | 2×420 | 2×25.2 | 1000 | 70 | 0~7 | 70 | 8350*4100*6800 | 119000 | |

| 10000 | 10000 | 9000 | 800 | 400 | 950 | 2×420 | 2×25.2 | 1000 | 70 | 0~7 | 70 | 10350*4100*7600 | 143000 | |

| 10000 | 12000 | 10000 | 800 | 400 | 950 | 2×420 | 2×25.2 | 1000 | 70 | 0~7 | 70 | 12350*4100*8500 | 167000 | |

| 12000 | 5000 | 4000 | 1000 | 400 | 1000 | 2×420 | 2×25.2 | 1000 | 60 | 0~6 | 60 | 5350*4200*6400 | 102000 | |

| 12000 | 6000 | 5000 | 1000 | 400 | 1000 | 2×420 | 2×25.2 | 1000 | 60 | 0~6 | 60 | 6350*4200*6600 | 112000 | |

| 12000 | 7000 | 6000 | 1000 | 400 | 1000 | 2×420 | 2×25.2 | 1000 | 60 | 0~6 | 60 | 7350*4200*6800 | 123000 | |

| 12000 | 8000 | 7000 | 1000 | 400 | 1000 | 2×420 | 2×25.2 | 1000 | 60 | 0~6 | 60 | 8350*4200*7000 | 135000 | |

| 12000 | 10000 | 9000 | 1000 | 400 | 1000 | 2×420 | 2×25.2 | 1000 | 60 | 0~6 | 60 | 10350*4200*7900 | 162000 | |

| 12000 | 12000 | 10000 | 1000 | 400 | 1000 | 2×420 | 2×25.2 | 1000 | 60 | 0~6 | 60 | 12350*4200*8800 | 186000 | |

- High precision linear scale

Equipped with linear scale that delivers measuring accuracy of 0.005mm, ensuring the synchronized operation of Y1 and Y2 axes.

- Mechanical compensation crowning table

Crowning table provides mechanical compensation to the deflections, ensuring the high precision of bending.

- Standard press brake tooling (punches and dies)

All punches and dies are quench hardened for high durability. (Custom press brake tooling is also available)

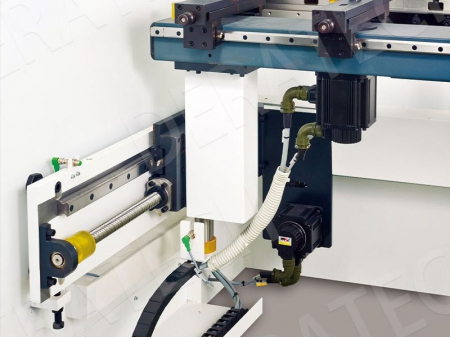

- Stable backgauge

Driven by servo motor and ball screw mechanism, offering rapid and efficient operation with high positioning accuracy; the design of multiple stations provides a wide handling range;

Single axis control or multiple axes control is optional; - Reasonable structure design

Standard configuration of 3 1 axes, i.e. Y1-Y2 axes (control up/down movement of left and right cylinders), X axis (controls the front/back movement of backgauge), W axis (controls mechanical compensation crowning table)

- Switzerland Cybelec CT12

- Italy ESA S640

- Italy ESA S860W-18.5

- Switzerland Cybelec VT-19