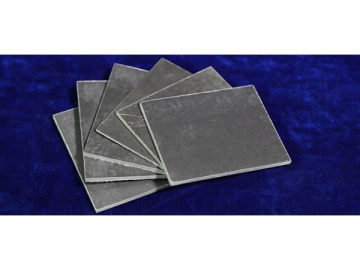

Functional Laminated Sheet

At Friend Group, you can also find a variety of laminated sheets with special functions such as magnetic conductive sheet, epoxy glass mat laminated sheet, semi-conductive epoxy glass cloth sheet and more. These laminated products provide special mechanical and electrical performances for various applications.

Process: Made through hot pressing and drying processes

Properties: The laminate material features great mechanical strength, heat resistance and magnetic conductivity.

Application: It is commonly used to make slot wedges for large size electric motors. The magnetic slot wedges are able to reduce motor temperature rise and thereby increase motor efficiency and service life.

(Similar to the EPGM203 Sheet of IEC Standard)

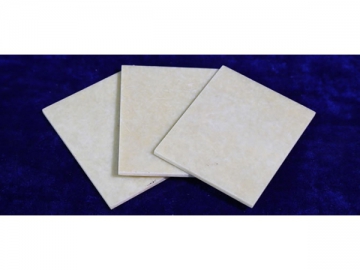

Process: Made through hot pressing and drying processes

Properties: Since the insulation material is made through hot pressing of glass mat instead of glass cloth, reinforced with epoxy resins, it features isotropy and is ideal for making insulation threaded rods, screw bolts and nuts.

Application: It is usually used for making the electrical insulator for H-grade motors and electrical equipment.

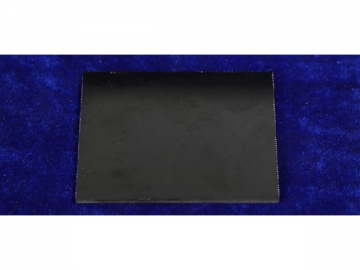

Process: Made through hot pressing of two or more layers of glass cloth, impregnated with epoxy resins.

Property: Excellent anti corona performance

Application: With excellent resistance to corona, the glass-reinforced epoxy laminate sheet is used as the anti-corona material in the slot of large size motor. In addition, it can be used as the material for non-metal parts working under high temperature.

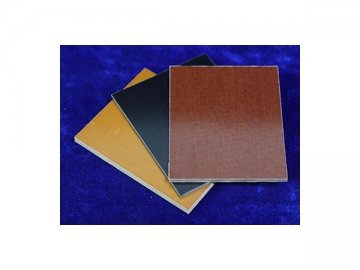

Process: The laminated material is fabricated through hot pressing of two or more layers of glass cloth, impregnated with melamine resins. It is equivalent to the G5 laminated sheet of NEMA standard.

Property: Excellent resistance to arc, tracking and flame.

Application: It is used to make the structural parts for electrical equipment. The structural parts are required to have high resistance to arc and surface fouling.

Process: The laminated sheet is made from two or more layers of glass cloth through hot pressing process, impregnated with benzoxazine resins.

Property: It is a high temperature resistant and flame retardant insulation sheet with superior electrical performance and stable mechanical strength in a condition where the temperature is increasing. Moreover, the laminate is halogen free and wear resistant.

Application: It is ideal for use under a high temperature, meeting the halogen free and fire resistant requirements.

Process: Made through hot pressing of two or more layers of glass cloth, reinforced with organic silicon resins.

Property: It features high mechanical strength, and excellent resistance to arc and high temperature. It can work for a long time under a high temperature of at least 180℃.

Application: The laminated sheet is suitable for making the slot wedges and cushion blocks for H-grade heat resistant motors and insulation structural parts for electronic use. Especially, it is great for making insulation parts in high demand for high temperature and arc resistance.

| Models | Specifications | |

| Thickness | Nominal size | |

| | 2 ~ 8mm | 1020 x 1220mm |

| | 0.5 ~ 50mm | 1020 x 1220mm |

| | 0.4 ~ 12mm | 1020 x 2040mm |

| | 0.5 ~ 50mm | 1020 x 2040mm |

| | 0.5 ~ 50mm | 1020 x 1220mm, 1020 x 2040mm |

| | 0.4 ~ 30mm | 1020 x 1220mm, 1020 x 2040mm |