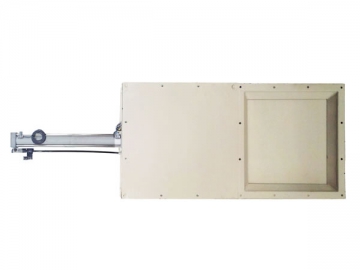

Grain Pre-cleaner

DEGAO has a wealth of knowledge in grain cleaning systems. Our design engineers would be more than happy to pick out the most suitable grain pre-cleaner for your industrial processes. We only ask that you supply us with your incoming product composition and desired outgoing product separation.

Features of Grain Pre-Cleaner

1. DEGAO grain pre-cleaner is quite effective with impurity removal tasks as more than 99% of rocks, straw, and large materials can be separated from the plump, full and clean grains.

2. A horizontal rotary sifter is used to separate granular materials according to their relative sizes and shapes. The sifter consists of a drum that can be further divided into two sections: feed and discharge. The two sections adopt different styles of screen openings to achieve the desired screening efficiency.

3. Incoming materials are fed to the grain pre-cleaner in the direction that is opposite to the outgoing grains.

4. The discharge section is fitted with a spiral chute to increase the distance that materials have to travel before exiting the sifter. Extended sifting length ensures grains are thoroughly separated by fineness and impurities are completely removed.

5. Under constant rotation, both fiberous materials and straw would roll into balls. At this point, an external brush is used to clear those balls out of the pre-cleaning system via the spiral chute.

6. A low power grain cleaning unit that gives high yields.

7. Common traits of our grain cleaner include great ease of sieve replacement, compact structure, small footprint and stable operation.

8. Widely used in animal feed, grease, flour, rice milling, grain warehouse, food, and chemical engineering industries.

| Model No. | ||||

| Productivity (t/h) | 10-20 | 20-40 | 40-60 | 60-80 |

| Power (kw) | 0.55 | 0.55 | 0.75 | 1.5 |