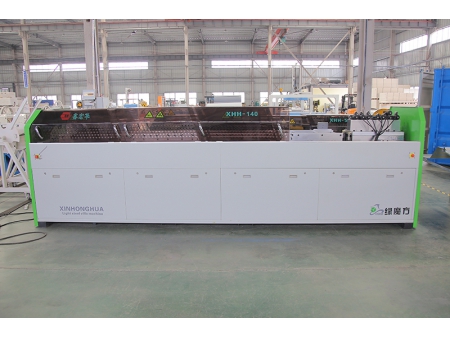

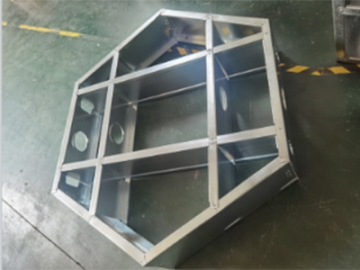

XHH-C310 Light Gauge Steel Framing Machine

Steel Frame Roll Forming Machine

XHH-C305/310 light gauge steel framing machine provides cold-formedform steel solutions to floor joist and trusses for residential and light commercial buildings. It is capable of producing 305/310 wide profiles, which features increased loading capacity by 10% compared to 89mm wide profiles and greatly saves steel. The machine comes with a production speed of 1.8t/h.

| Model | C305/310 |

| Dimension | 7600*1500*1700mm |

| Main Servo Motor Power | 22kW |

| Hydraulic Motor | 11kW |

| Forming Steps | 12Steps |

| Forming Speed | 15tons/8hours |

| Voltage | 380V/50Hz/3Phase |

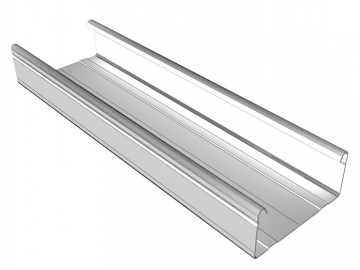

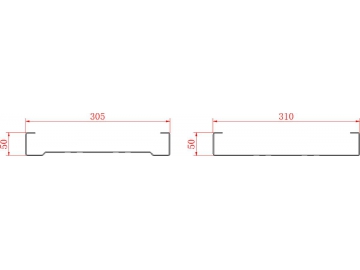

| Effective Width | 305mm, 310mm |

| Material Width | 425mm |

| Flange Height | 50mm |

| Lip | 12mm |

| Material Thickness | G300-G450: 0.95-2.5mm G550: 0.95-2.0mm |

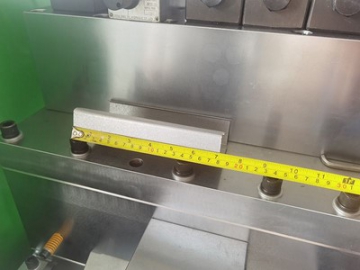

| Tolerance for Cutting and Punching | ±1mm |

| Tolerance for Forming | ±1mm |

| Control System | IPC computer controlling system |

| Design Software | Vertex Software |

| Rollers | Made using SKD-11 steel with heat treatment, plate hard chrome on the surface of rollers |

| Material for Shaft | SKD-11 |

| Material for Puncher | SKD-11 |

| Material for Cutter | SKD-11 |

-

Post punching mould

XHH LGS Machine all with post punching and post cutting, which make more high precision performance on position & dimension

-

Lower material wasting

Short distance between punching & cutting die limits the start-up material waste length at 0.2m, and end material waste length within 1 meter.

-

Save Cost

The length of each start-up waste of the XHH post-punching & cutting machine is about 1m. Most machines on the market are pre-punching & post-cutting (other suppliers), thus the waste material is about 8m on each start-up.

Start-Up/Change Steel Coil 8.11-12.13 kg 5 Steel Coils/Day 8.11-12.13 kg Material Saved/Year 12.17-18.2 T

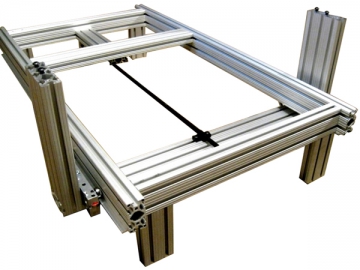

- Main forming system

- 5 Tons Hydraulic Uncoiler

- Servo motor system

- IPC computer controlling system (Lenovo Laptop)

- Production software (1set)

- Design Software-Vertex, forever using license

- Hydraulic Automatic Punching Device (Lip Notch, Swage, Big Service Hole, Triple Web Hole, Triple Flange Hole)

- Hydraulic post-cutting device (material: SKD-11)

- Automatic printing device

- Run out table (4m)