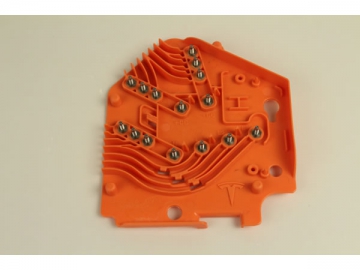

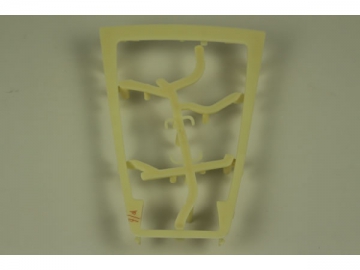

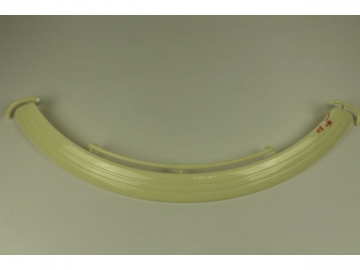

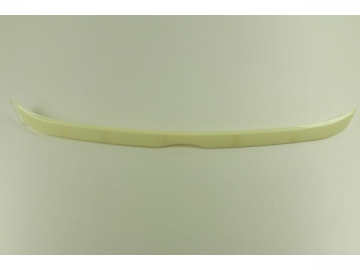

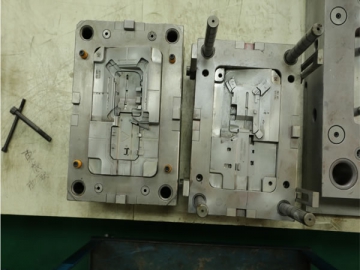

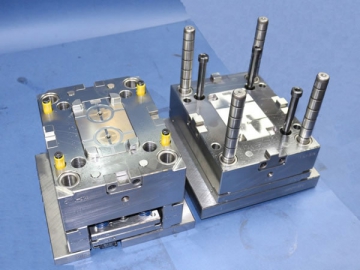

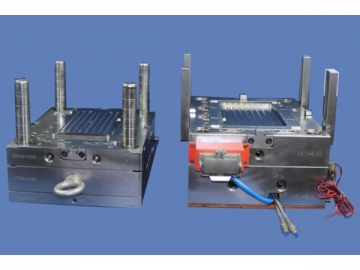

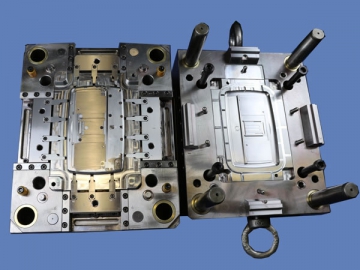

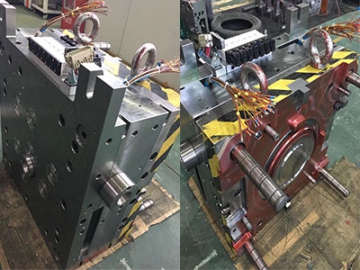

Plastic Injection Mould (Supplying Auto Parts Mould)

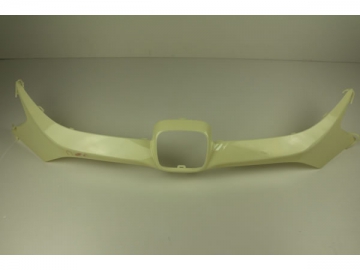

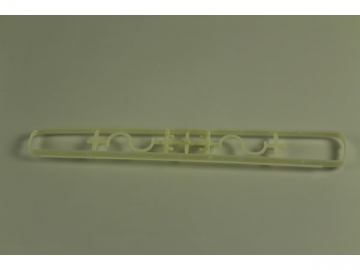

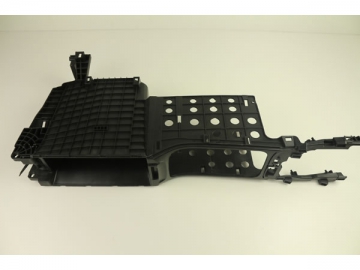

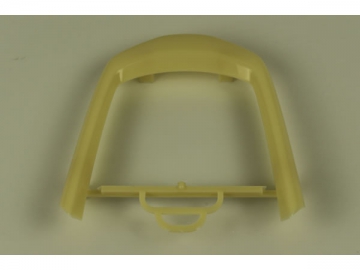

With rich experience in mould products design and manufacturing, our company is specialized in supplying plastic injection moulds for auto parts. The auto parts moulds we make are well accepted by auto parts factories, car repair shops and automobile manufacturers due to their excellent workmanship, high precision and superior quality. So far, we have provided superior bezel moulds, grille moulds, connector moulds and electroplated auto parts moulds for automobile companies and professional auto parts companies in Japan, America and Europe. With rich mould manufacturing experience, our company is able to meet your personalized requirements on plastic injection moulds.

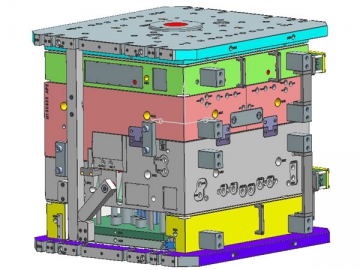

In order to avoid deformation of the finished auto parts, as a professional plastic injection mould manufacturer, we shorten the runners of our plastic injection mould and arrange the mould' plastic injection gate, ejection gate and air vent in a reasonable way to achieve uniform mould cooling. To guarantee the finished moulded products are in uniform thickness, we set the plastic injection gate in the thicker part of the product with the help of professional mold flow analysis.

Our company has the following advantages in making auto parts moulds

1. We have professional and experienced work team taking change of auto parts moulds design and manufacturing.

2. During price inquiry process, cost beak down is available for helping customers control the purchasing and production cost.

3. After the project has been confirmed, we offer mold flow analysis report and DFM report to work out an optimal plastic injection mould solution.

4. In the mould manufacturing process, the production progress will be shared with the customers in real time.

5. Obtaining the TS16949 certificate, our company can provide one-stop services of auto parts mould manufacturing and auto parts production for customers in auto parts industries.

Moulded Product Sample Display