Blow Moulding Machine

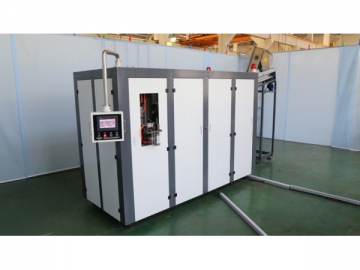

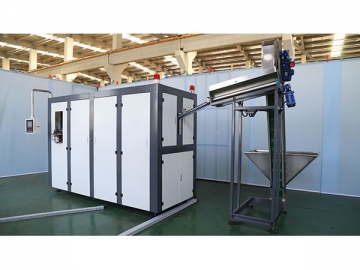

Pictured is a blow molding machine we made 8 years ago. It is still running in tip-top condition. Dahong blow molding machine is the go-to solution for blowing preforms of various sizes into the shape of the finished bottle. This high level of flexibility saves money for bottling plants, as there is no restriction on the size of soda bottle preforms.

Features

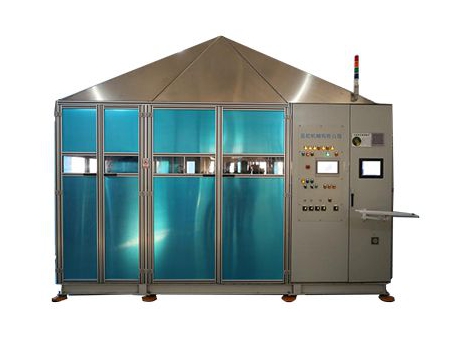

1. Fast, productive blow molding operation yields 4000 soda bottles (0.5L) or 1600 soda bottles (5L) per hour.

2. Reliable Schneider electrical system uses servomechanisms to correct the performance of the blow molding unit. Machine components are made using NC lathe.

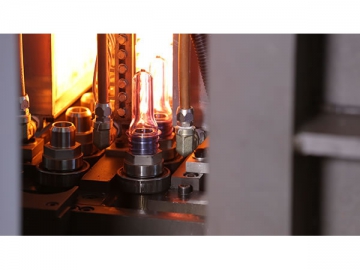

3. Energy-saving, low-profile holding trays hold each bottle preform on a piece of plate along the conveyor. Single heating tube generates heat on both sides to save electricity. High-pressure exhaust gas is re-circulated through the pneumatic system for maximum gas savings.

4. Dahong blow molder delivers more than 30% energy savings compared with competitive products on the market.

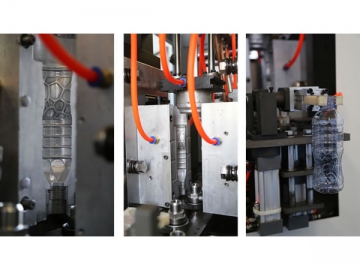

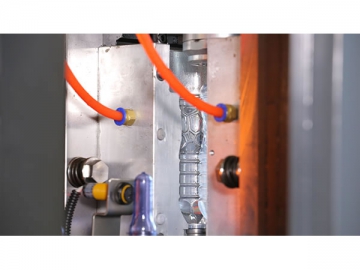

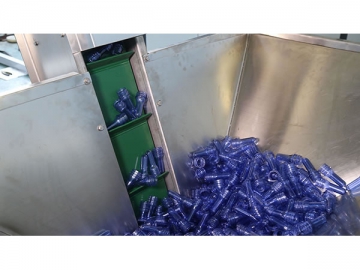

5. By changing in and out different molds, operators can produce different soda bottle shapes. Dual-station blow molding machine using single-cavity molds allows the production of different bottle shapes on two stations at the same time using the same blanks (preforms).

6. Accommodates various preform materials and quality grades. Optimized blow molding technology allows the machine to adjust itself according to different preforms.

7. Real-time monitoring of the machine's operating status. Displays running data clearly.