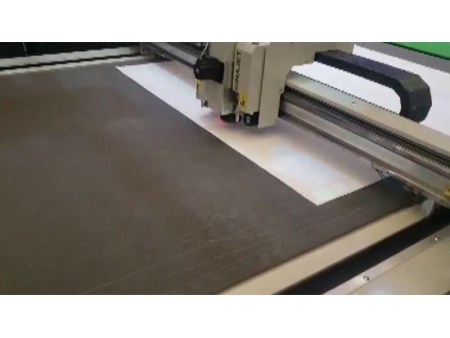

Digital Cutter for Textile/Garment Industry

Request a Quote

- 3m Fabric Cutting with Auto Feeding

- 30-Layer Lining Cutting

- Digital Cutting with Camera Scanning

- Digital Cutting with Video Projection System

- Shirts Cutting with Video Projection System

Modular combination of cutting knives:

high speed rotary knife, notching tool, drilling tool and more cutting tools to meet a number of apparel fabric cutting application needs;Advanced software:

it can satisfy your individual production demands;Inkjet tool/plotting pen:

it is used in cutting operations where cut parts need to be marked;Various custom-specific requirements are acceptable

Applications:

made to measure (MTM) custom clothing, sample cutting, small batch garment manufacturing

Options

There are six models available to meet different needs. Those models vary from the cutting area (L*W). Customized machine model can be offered upon request.

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, notching tool, drilling tool, punching tool and more knives are optional

- Marking modules: Inkjet tool and plotting pen are optional

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF/AI/PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 5.5-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, notching tool, drilling tool, punching tool and more knives are optional

- Marking modules: Inkjet tool and plotting pen are optional

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF/AI/PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 5.5-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, notching tool, drilling tool, punching tool and more knives are optional

- Marking modules: Inkjet tool and plotting pen are optional

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF/AI/PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 5.5-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, notching tool, drilling tool, punching tool and more knives are optional

- Marking modules: Inkjet tool and plotting pen are optional

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF/AI/PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 5.5-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, notching tool, drilling tool, punching tool and more knives are optional

- Marking modules: Inkjet tool and plotting pen are optional

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF/AI/PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 5.5-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

- Repeatability: ≤0.1mm

- Max. cutting thickness: 25mm

- Max. cutting speed: 1500mm/s

- Cutting tools: rotary knife, notching tool, drilling tool, punching tool and more knives are optional

- Marking modules: Inkjet tool and plotting pen are optional

- Material hold-down: vacuum clamping

- File format: DXF/ HPGL/ CUT/ GBR/ PLT/ ISO/ PDF/AI/PDF

- Interface: network interface

- Voltage: 220V/380V/50-60HZ

- Drive system: intelligent digital servo drive

- Pump power: 5.5-9.0KW

- Working environment: temperature 0-40℃; humidity 20%-80%RH (non-condensing)

Sinajet offers custom-manufactured digital cutting systems for the field of garment and apparel manufacturing, they are suitable for cutting various woven and knitted fabrics to make suits, shirts, dresses, and much more types of apparels. High resolution vision camera system is equipped for precise locating and contour cutting of stripes, plaids and different patterns in a fast manner. Besides, our digital cutters are offered with user-friendly operating system, creating a perfect platform for your clothing manufacturing.

Features

Automatic Nesting

It achieves fully automatic nesting on textile while matching to stripes and plaids, with the highest utilization of material. This provides the best possible cutting layout and gets jobs into production faster and more precise.

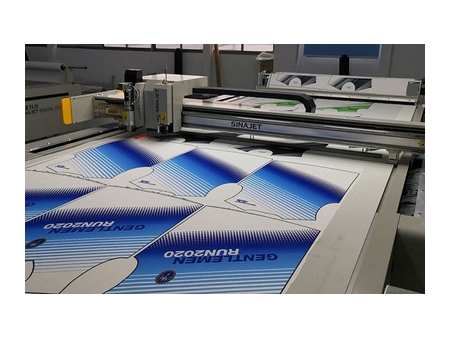

Vision Scan Contour Cutting

The vision system recognizes contour marks printed on various materials, and then the precise cutting is automatically implemented. The entire process eliminates the need for manual cutting where paper pattern is required.

Conveyor Table and Off-load Table (integrated)

It allows operator to collect cut piece while the machine is continuously working, improving cutting efficiency.

Automatic Layout and Cutting for Horizontal Striped T-shirt

The vision system automatically recognizes horizontal stripes to achieve automatic layout and cutting, eliminating the need for manual operation during the entire process.

Innovative Cutting for Knitted T-shirt

It enables the operations from fabric feeding, cutting to cut piece collection to be completed in an efficient manner, which requires only one person to operate. It is a perfect way solving the elastic deformation of knitted fabric.

Simultaneous Feeding and Cutting

This provides unmanned operation through automatic fabric feeding and cutting, ensuring high efficiency for uniforms and clothing manufacturing.

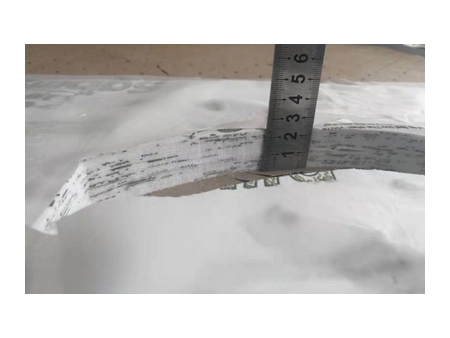

2.0cm High Accuracy Cutting

It satisfies the needs of multi-layer cutting for small batch production.

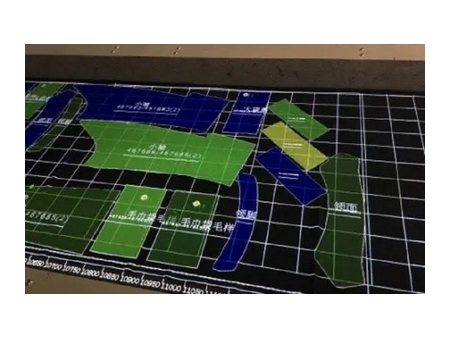

Projection System for Precise Cutting

Projection system for cut path alignment can efficiently replace the conventional manual cutting method that requires paper patterns.

Dynamic Projection with Various Colors

Objects are projected with various colors, providing effective sorting of cut pieces. It allows operator to better recognize the material to be cut, preventing cutting errors.

Glue Dispensing

Automatic glue dispensing is used for the seam line of trouser, eliminating the need for manual operation.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos