Safety Device

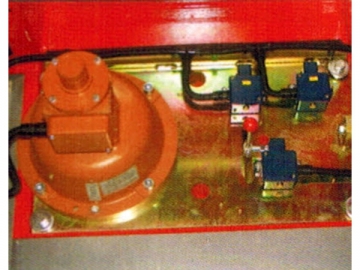

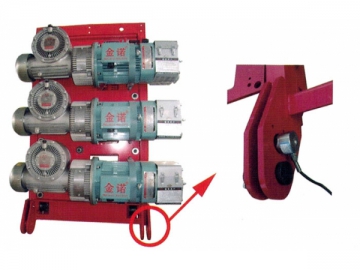

Safety devices, or safeties, are critical elements of any construction hoist. They prevent an elevator from plummeting down the hoistway causing catastrophes when something goes wrong. Safety systems provided by Jingya are engineered and manufactured by Shanghai Research Institute of Building Sciences (SRIBS) to ensure they provide dependable emergency braking performance.

Sure, there are many elevator safety device providers in China. Our safety system is robust, reliable, cost effective and easy to maintain. Can they say the same for their products? Compare our safety system with any other safeties offered by our competitors, you'd soon discover why most customers choose us over the rest. We provide these construction hoist safety devices in various series, including SAJ02-1.2, SAJ08-1.2, SAJ30-1.2, SAJ40-1.2, SAJ40-2.0, SAJ50-2.0, SAJ60-2.0, and SA/70-1.4, etc.

To facilitate the maintenance of our elevator braking system, we revolutionize the way braking components are lubricated. Now maintenance staff can add lubricating oil to the braking system while they are in the elevator car. No more dangerous climbing.

As the geared elevator becomes a more pervasive element in the society, we have developed a safety device with a speed booster built in it. In addition to being used in construction elevators, our safety systems are also widely found on motors in wind turbines, dock cranes, and elevated platforms. Technically speaking, any gear-driven machinery can use our safety device.

Frequently Asked Questions

1. How long is your safety device designed to last?

Any safety system has a limited lifetime. Our safety product has a warranted operating life of 5 years from the day the product leaves factory.

2. Any maintenance or inspection is required throughout its guaranteed lifetime?

Gear needs lubricating every 120 hours of use. Please see our instruction for detailed information. Each safety system needs to be inspected every year for proper functioning.

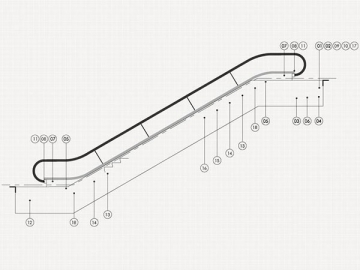

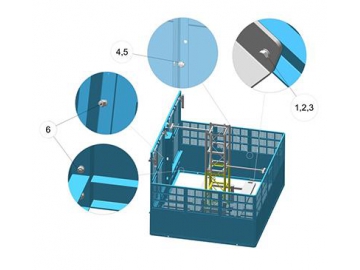

3. How can I make sure the safety system is secured in place?

First off, the bolts you use for securing the safety system should not be lower than grade 8.8. Meanwhile, be sure to tighten each of four bolts evenly.

Secondly, check if the gear rack and pinion are engaged properly after installation. Gear backlash for SAJ02-1.2 and SAJ08-1.2 should fall between 0.3mmm and 0.7mm. Gear backlash for the rest should be controlled between 0.5mm-1.0mm. Rotate the gear wheel manually, and you should feel it sways slightly. Backlash can be measured by means of feeler-gauge or lead-wire.

Last but not least, make sure the normally-closed contacts of the limit switch are wired into the elevator control circuit which controls the downward movement of the elevator. Failure to do so may lead to serious consequences.

4. How to deal with abnormal safety brake noise during operation?

The abnormal sound of the safety system may be caused by many different factors. Please refer to our website for related information.

It is strongly recommended that the safety system should be placed in a hermetically sealed environment. The response speed of the flyweight has been adjusted by using specialized equipment, not by relying on experience or naked-eye observing. Unauthorized opening of the safety device is forbidden. In the meantime, we do not provide parts replacement, on-site installation or operator training services for buyers outside China. So, first-time buyer is advised to order a little more than is needed for a rainy day.