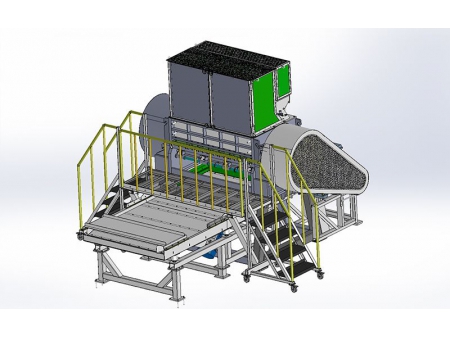

Tyre Debeader (Tyre Bead Cutter)

From complete turnkey factories to individual machines, TIANTIE can provide customers with a wide range of standard equipment and custom recycling solution to help them achieve their business goals.

The entire tyre recycling system involves multiple processes, and the tyre debeader is the first processing equipment in the waste tyre recycling and processing industry.

Tyre debeader is a device that efficiently pulls both beads from both sides of a tyre at the same time. Removal of the bead wires facilitates the subsequent shredding of the whole tyre into rubber chips.

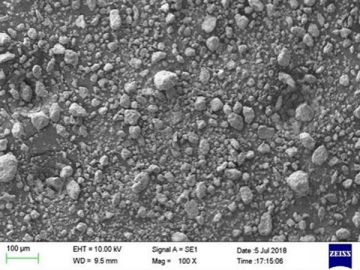

The tyre bead cutter plays a crucial role in rubber and tyre recycling processes as it helps reduce the volume of waste tyres and facilitates further processing. The recycled tyre shreds can be used as raw materials for other products such as tyre-derived fuel, rubber mulch, playground surfaces, and more.

- Capacity: 30-40 beads/hour

- Tyre Diameter: ≤1200 mm

- Motor Power: 5.5 kW

- Hydraulic Power: 2.2 kW

- Weight: 2.65 T

- Dimensions: 3290×1240×1377 mm

- The tyre is lifted by a hydraulic cylinder and transferred by the movable frame into the bead locking device, featuring simple operation and high level of safety.

- The cutting blade and guide rail are made of special materials, ensuring high strength, wear resistance, and durability.

- The tyre debeader is equipped with a tyre lifting device, allowing for breaking tyres with an outer diameter ≤1200mm, reducing labor and increasing productivity.

- The tyre lifting and positioning program is manually controlled, while the bead locking and cutting operations are automatically completed. The tyre speed can be adjusted through frequency control, ensuring precise and reliable operation with high efficiency.

- The hydraulic system adopts internationally advanced constant power variable plunger pump technology, resulting in low working noise, high pressure, and ensuring the equipment's lifespan and safe operation of the control system.

Talk to Waste Initiatives today to find out more about our waste & recycling solutions.