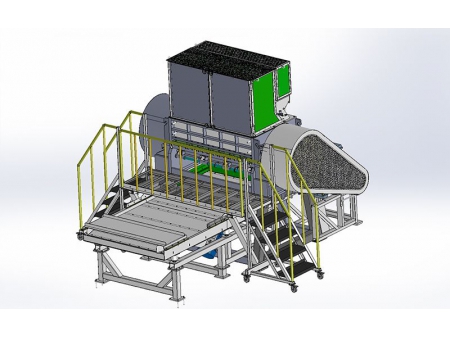

Tyre Chip Shredder

Tyre chip shredder is mainly composed of a feeding hopper, main shaft, and discharge hopper. It can crush rubber chips smaller than 50*50mm into smaller rubber particles measuring 18-20mm. The fixed blade has a service life of over 9000 tons, while the moving blade has a service life of over 4000 tons. The blades are detachable or repairable, ensuring a long lifespan and convenient maintenance. This size reduction machine has stable performance and a high load capacity, capable of shredding large and hard rubber chips, saving significant space and transportation costs.

The tyre chip shredder consists of a feeding hopper, upper body, lower body, V-belt, main shaft, bearings, short blade, long blade, a screen insert, and a discharge hopper.

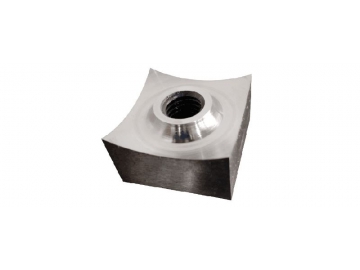

| Number of Blades | 120 pieces | |

| Blade Size | Ø600×112mm (diameter × thickness) | |

| Working Length of Cutting Chamber | 1600mm | |

| Output size | 18mm-20mm rubber chips | |

| Shaft | Material | 42CrMo |

| Speed | 260r/min | |

| Capacity | 3000kg/h | |

| Motor | Brand | SUNVIM |

| Power | 132kW | |

| Bearing Brand | Wafangdian Bearing (Harbin) | |

| Dimensions (L×W×H) | 3800×3200×3667mm | |

| Weight | 11000kg | |

| Blade Usage | Service life of moving blades is more than 9000 tons, and service life of fixed blades is more than 4000 tons. Damaged blades can be removed and repaired multiple times. | |

This tyre shredding machine is suitable for industrial rubber processing and recycling, capable of crushing rubber chips smaller than 50*50mm into smaller rubber particles.

- The processing of the shredder body has high accuracy in key dimensions, ensuring smooth and safe operation of the equipment.

- The slope of the top feeding hopper of the shredder has been adjusted through experiments to greatly improve its material guiding function. The front end is designed with a window structure for easier maintenance and repair.

- The main shaft of the shredder is made of 42CrMo and undergoes vacuum heat treatment. The high-precision processing and tight clearance between the blade seat ensure stable and uniform operation.

- The moving and fixed blades of the shredder are made of high-hardness special customized steel, providing good wear resistance and high hardness.

- The bearings of the shredder are oil-cooled to prevent high temperature during operation, extending the working time and service life of the machine.

- The bottom support of the shredder is welded with high-strength square tubes, and the welding structure has high strength. The bottom is equipped with anchor bolts to enhance stability and reduce vibration.

Talk to Waste Initiatives today to find out more about our waste & recycling solutions.