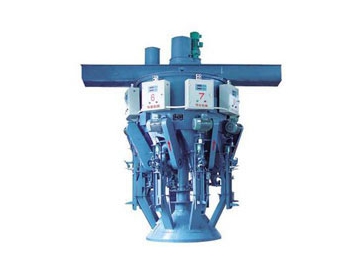

Automatic Bagging Scale, SYC-DCS-900Z Weigh Bagging Machine

The SYC-DCS-900Z automatic bagging scale suitable for 5-25kg woven bags and plastic bags, and carries out vacuum packaging for rice, coarse grains and other granular materials. It automatically carries out feeding, weighing, feeding bags, clamping bags, filling, sealing and packaging, and is adaptable to packaging a variety of different materials.

Weighing range: 5-25kg

Weighing error: ±0.1%F.S

Weighing speed: 400-960 (bag/h)

Air pressure: 0.5-0.7 Mpa

Total air consumption: 6m³/h

Total power consumption: 9Kw three phase 5 wire(woven pag packaging)/12Kw (vacuum packing)

Ambient temperature: 0-40 ℃

Ambient humidity: no more than 90% RH at 40 degrees centigrade, allowing greater humidity at low temperatures.

Dimension (length * width * height): 6172*3742*3321mm

1. Complete function

1) The packaging machine features 3 different functions: woven bag packaging, inflatable packaging and vacuum packaging.

2) The bag feeder's bagging scale is a combination of a horizontal bag feeder and vertical bag feeder, and can be used for both woven bags and packaging bag with handle.

2. High degree of automation

1) After manually placing the bag, the weigh bagging machine will automatically supply, load, open, detect, weigh, fill with carbon dioxide, fill with the granular material, seal, and vacuum the bag. This equipment also features a fault alarm.

2) The SYC-DCS-900Z automatic bagging scale uses a servo and touch screen, PLC programmable control system, and a clear, easy to use human-machine interface.

3. Excellent safety and long service life

1) It uses a closed structure, and a chain device. If staff interferes with the equipment, it will automatically stop and sound an alarm. It will not restart until a manual confirmation reset has occurred.

2) Both the feeding mechanism and the measuring mechanism are in an airtight working room, which isolate against corrosion and wear to the cylinder and sensor caused by rice flour and water vapor. This significantly extends the service life.

4. Strong stability and strong interference resistance

1) The quantitative bagging scale uses three sensors, which greatly improves the stability and anti-interference ability of the equipment.

2) The independent single cylinder feeding mechanism means each cylinder only completes one action, which is different from a traditional design of one gas powered cylinder to complete 3 actions. This more than doubles the cylinder's service life.

5. Weighing effect

1) The external weighing mechanism is a handle for the scale. Using the calibrated handle adjustment device, the inlet size can be adjusted according to different rice grain sizes and different moisture content levels, ensuring the best operation mode is carried out.

2) Optional: Internet of Things cloud technology, wireless data transmission function, online diagnosis function, online service function.

The bagging scale is composed primarily of the mechanical components and electric control components.

The mechanical components include the filling mechanism (which uses a weighing sensor to collect the weight signal), the automatic bag making mechanism (formed using the molding device), the sealing mechanism, and the pneumatic sealing transmission system.

The electronic control components include the electric control, the logic control unit, and an independent temperature control unit (which is controlled using a programmable controller and microcomputer processing)

Cylinder

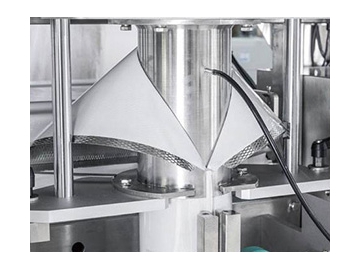

Cylinder  Sewing Bag Device

Sewing Bag Device  External Adjusting Handle

External Adjusting Handle  Sensor

Sensor